Electromagnetic drying heating equipment

A technology for drying heating and equipment, applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of open fire safety hazards, easy aging of resistance wires, high economic costs, etc., and achieve long trouble-free time, man-machine Superior aspect, good drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

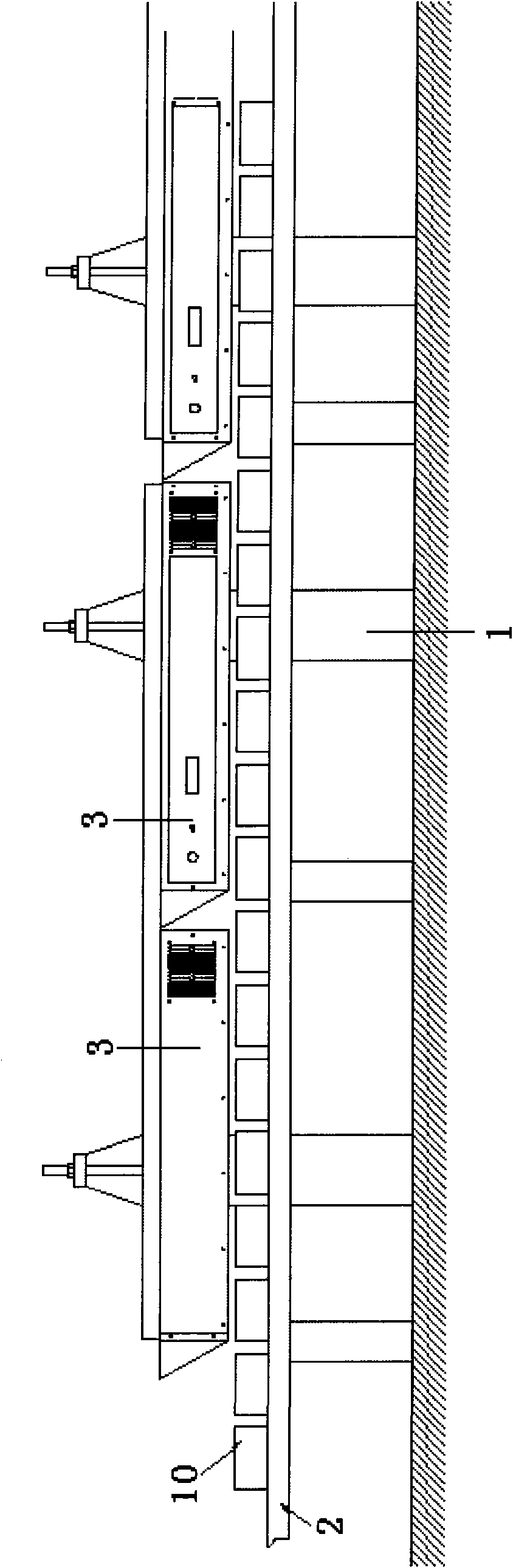

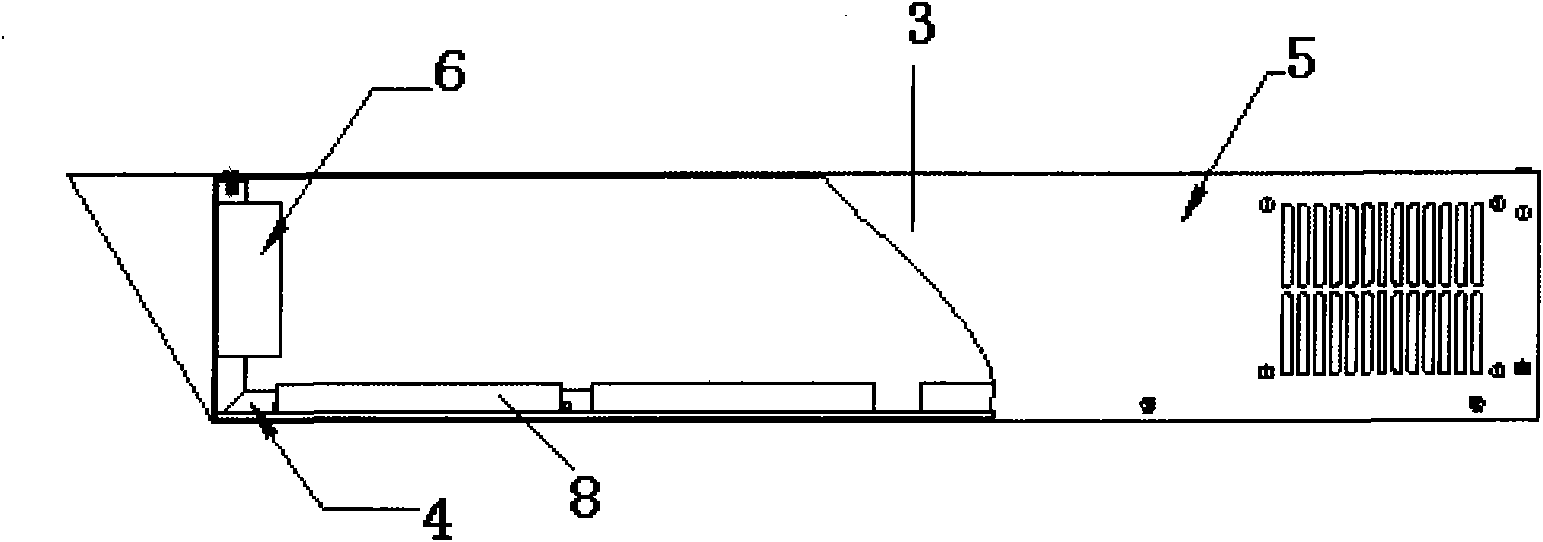

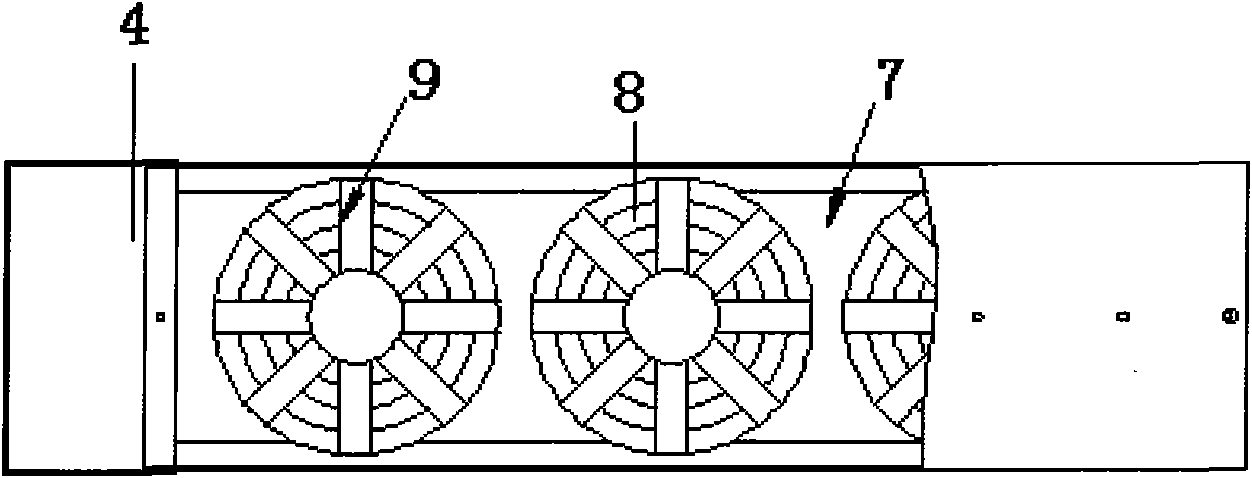

[0023] An electromagnetic drying and heating equipment, comprising a frame 1, left and right gears are respectively installed at both ends of the frame 1, and a transmission belt 2 for circulation transmission is set on the left and right gears, and a transmission belt 2 arranged in a row is installed on the frame 1. The heater 3, the heater 3 is located above the transmission belt 2. Each heater 3 includes a base plate 4 and a loam cake 5 covered on the base plate 4, an air duct is formed between the loam cake 5 and the base plate 4; a fan 6 is installed at the air inlet of the air duct, and The air outlet of fan 6 faces in the air duct. A glass-ceramic 7 is fixedly installed on the bottom plate 4 , and a number of serial or parallel coil disks 8 are arranged and distributed on the glass-ceramic 7 , and a magnet block 9 is pasted on the upper surface of each coil disk 8 . A temperature sensor is installed on the heater 3 .

[0024] During the working process, the tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com