Load cell for detecting supporting force on load-bearing support element

A technology for load cells and support components, which is applied in the direction of weighing equipment, special scales, and force measurement using elastically deformable components, and can solve problems such as contamination of support components and damage to sensitive measuring instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

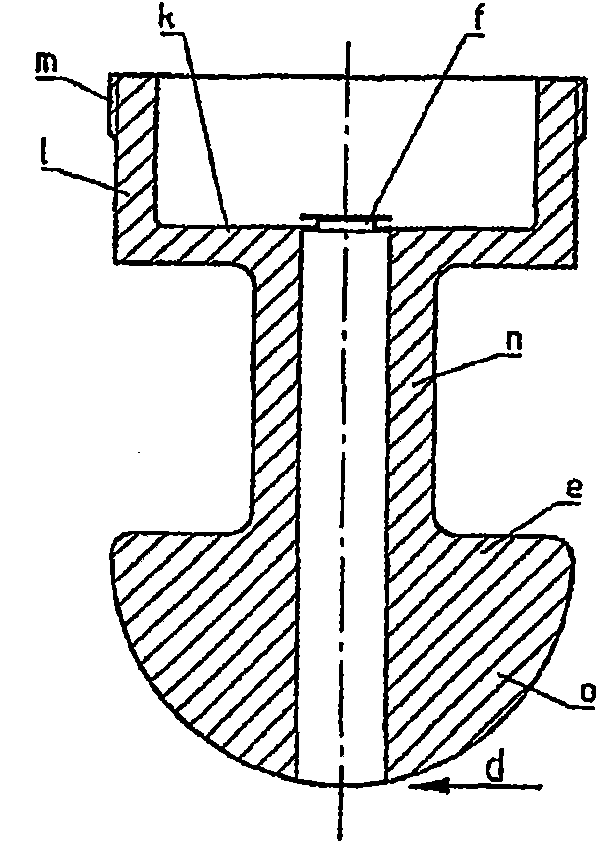

[0032] according to image 3 , the load cell consists of a steel rust-resistant deformable part e, the strain of which is induced by the force to be measured is not detected by means of strain gauges glued to this part, but by means of strain-sensitive resistors manufactured using thin-film technology . This has the advantage of high long-term stability, since thin-film resistors produced in thin-film technology are not glued to the carrier, but are adhered to the carrier as a composite of atoms by cohesive sputtering.

[0033] according to Figure 4a , 4b , thin-film resistors are provided on the end faces of the flat cylindrical carrier f initially separated from the load cell, the material of which corresponds to that of the deformed part, or at least exhibits similar thermal expansion properties. During the processing of the load cell, the carrier part and the deformation part are adhesively bonded together at their outer edge g by means of welding laser or electron bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com