Manufacturing unit for integrated thin film solar cells

A technology for thin-film solar cells and manufacturing devices, which is applied in the direction of fine working devices, manufacturing tools, and final product manufacturing. Excellent linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, details of the present invention will be described in detail based on the drawings showing embodiments of the present invention.

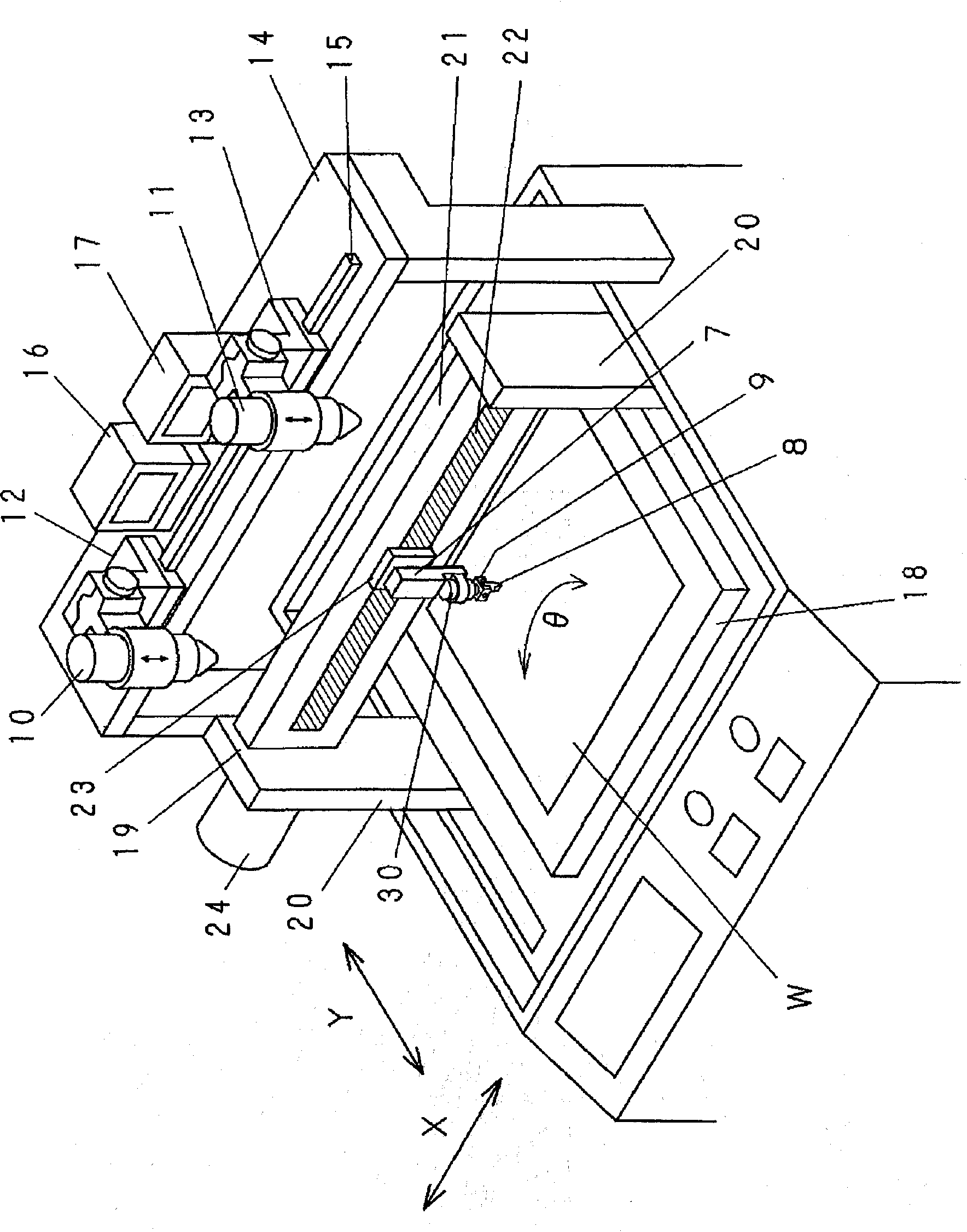

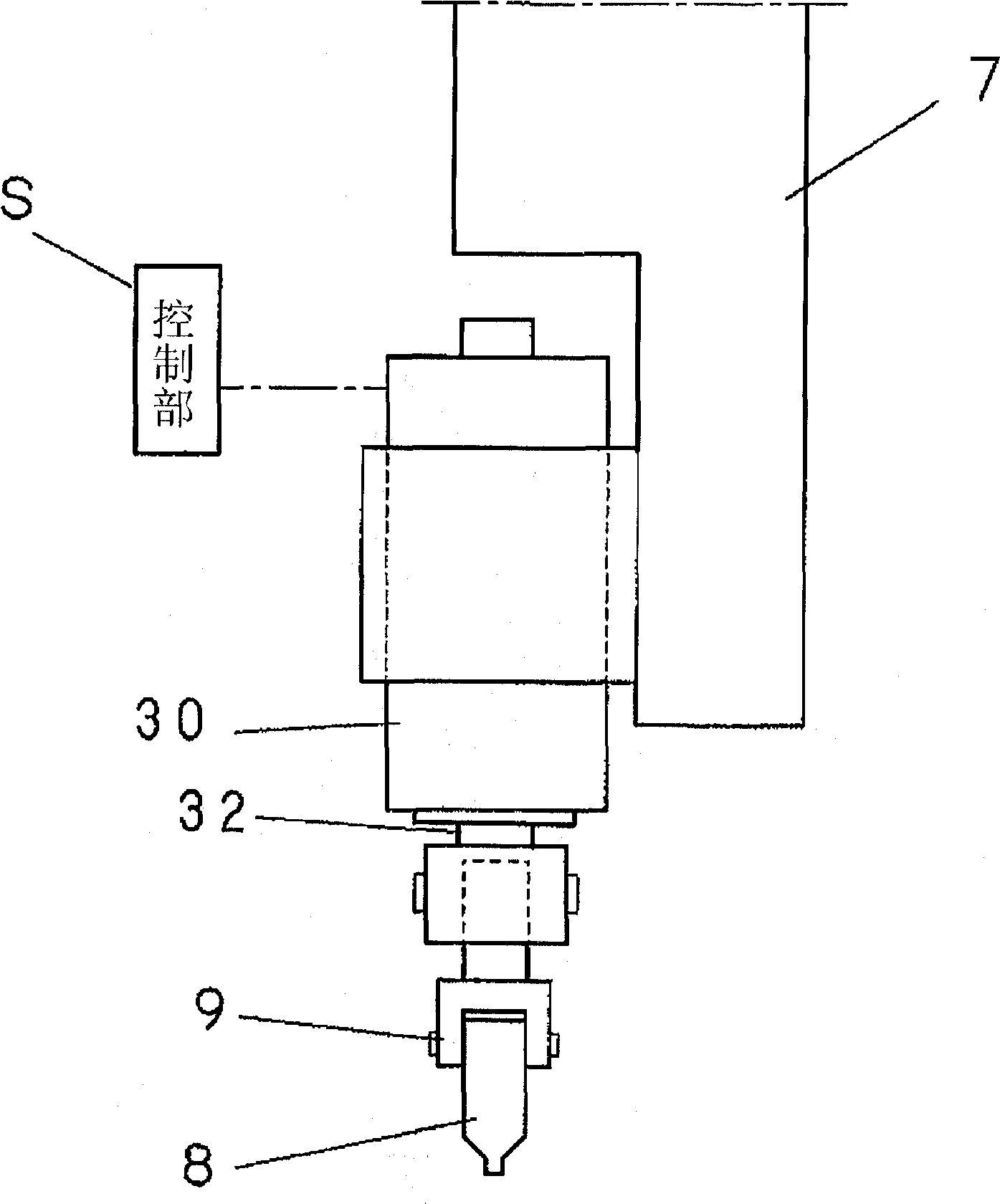

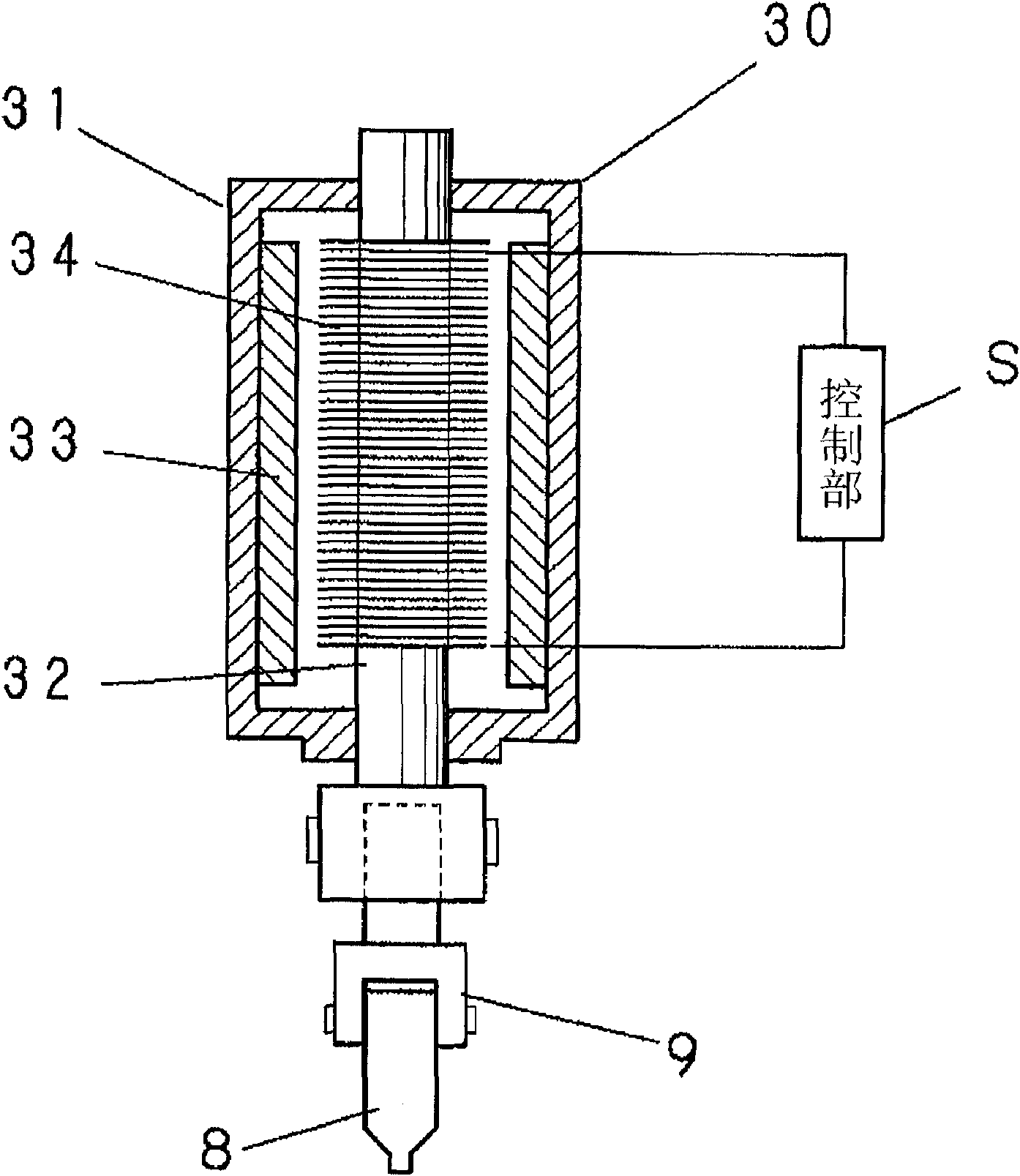

[0048] figure 1 It is a perspective view showing an embodiment of the manufacturing apparatus of the integrated thin film solar cell of the present invention. The device has a platform 18 that can move in the horizontal direction (Y direction) and can rotate 90 degrees and an angle θ in the horizontal plane. The platform 18 essentially forms a supporting mechanism for the solar cell substrate W.

[0049]The bridge body (bridge) 19 is arranged across the mode on the platform 18, and the bridge body 19 includes supporting columns 20, 20 on both sides of the clamping platform 18, and a guide bar (guide bar) extending in the X direction. )twenty one. The bracket supporting body 23 is movably installed along the guide 22 formed on the guide bar 21 , and is moved in the X direction by the rotation of the motor 24 .

[0050] A scri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com