Hollow fiber ultra-filtration membrane assembly having wave division plate

A separation plate, wave-shaped technology, applied in the field of hollow fiber ultrafiltration membrane modules, can solve the problems of easy clogging, easy breaking, and inability to flush the membrane, and achieve the effect of increasing the effluent flow rate and easy backwashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

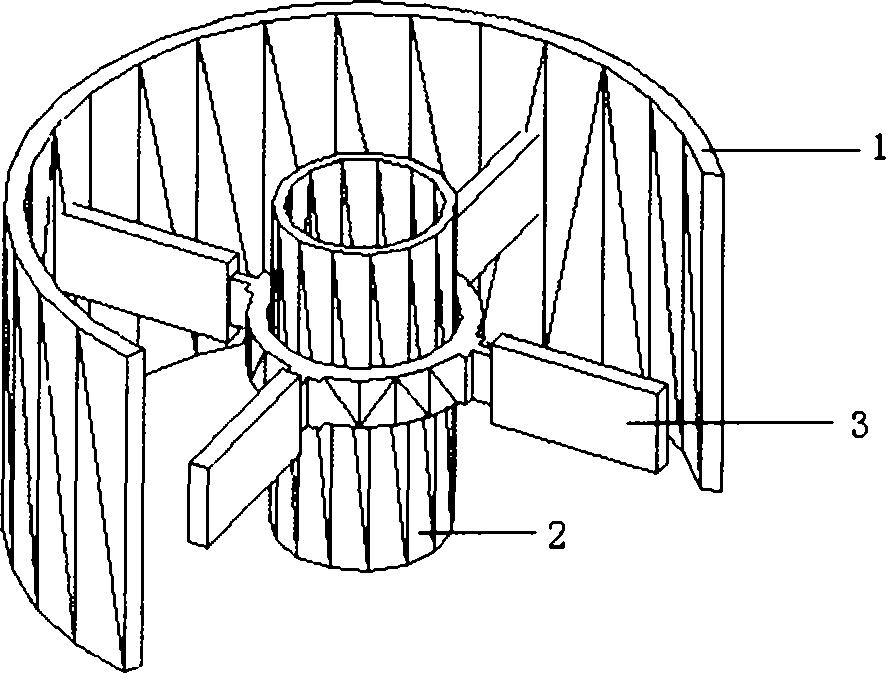

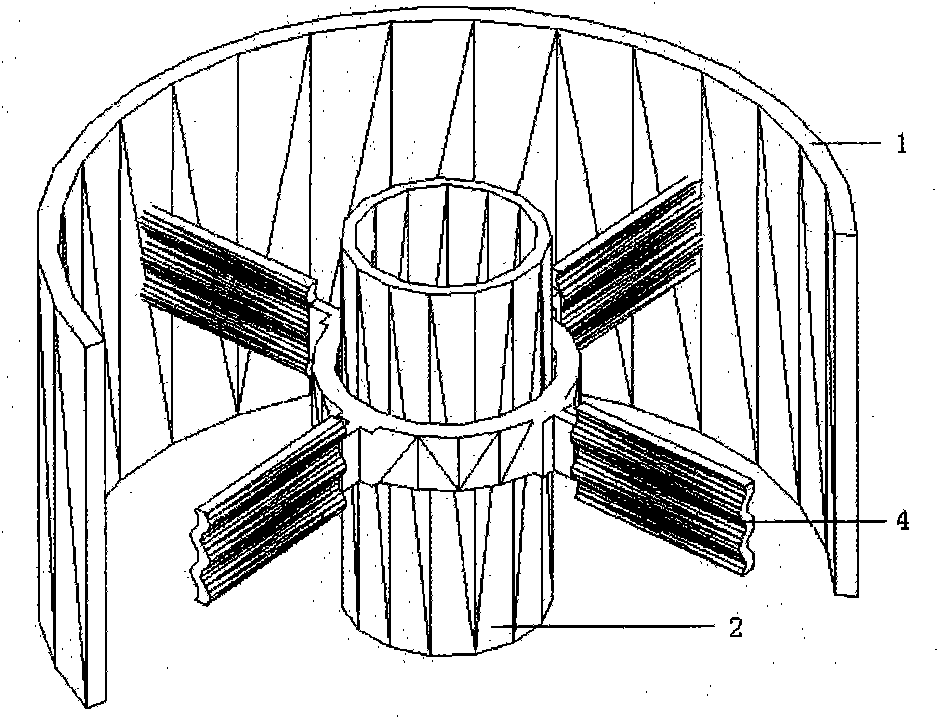

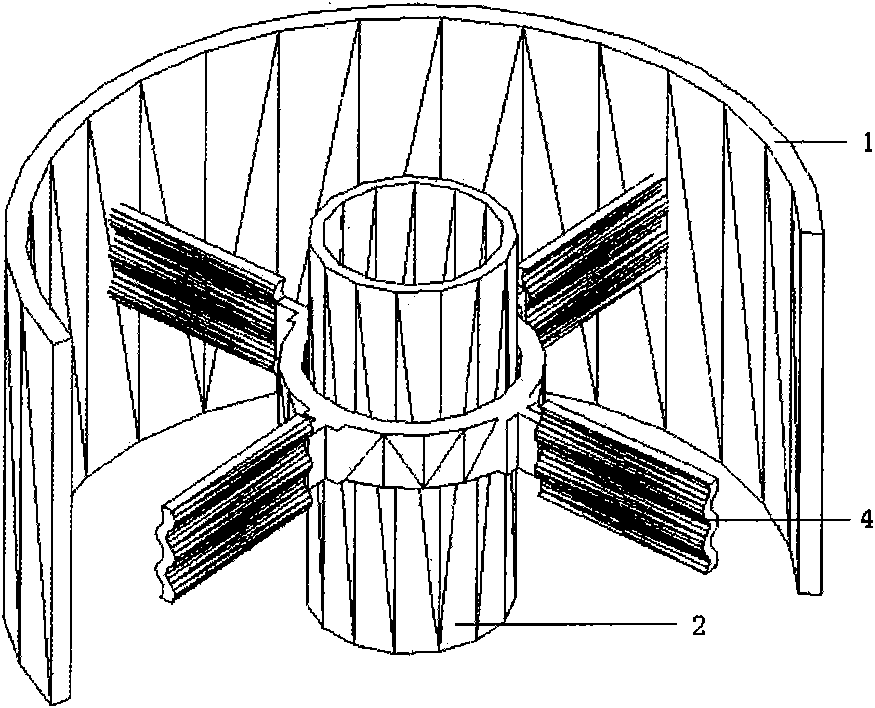

[0010] Such as figure 2 Shown is a schematic structural diagram of a hollow fiber ultrafiltration membrane module with a wavy separator. The hollow fiber ultrafiltration membrane module with wavy partitions is composed of a pressure-bearing shell 1 , a hollow conduit 2 , ultrafiltration membrane filaments and a wavy partition 4 . The center of the pressure-bearing shell 1 is provided with a hollow conduit 2 along the axial direction, and at least two corrugated partition plates 4 are arranged radially between the hollow conduit 2 and the pressure-contained shell 1. Filter silk.

[0011] During use, enter water from the water inlet on the pressure-bearing shell 1 and the hollow conduit 2, wash the ultrafiltration membrane wire, and discharge water from the water outlet on the pressure-bearing housing 1. The separation effect between the rooms is good, the flow rate of the water outlet is increased, and it is easier to backwash and positively wash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com