Supercharged empty hub propeller for ship

A propeller and hollow hub technology, which is applied in the direction of ship propulsion, propulsion components, propulsion device engines, etc., can solve the problems of unadjustable propellers, reduced water flow velocity and water pressure, and reduced propulsion efficiency, so as to improve the scope of use and use Efficiency, water flow rate and water pressure increase, and the effect of increasing propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

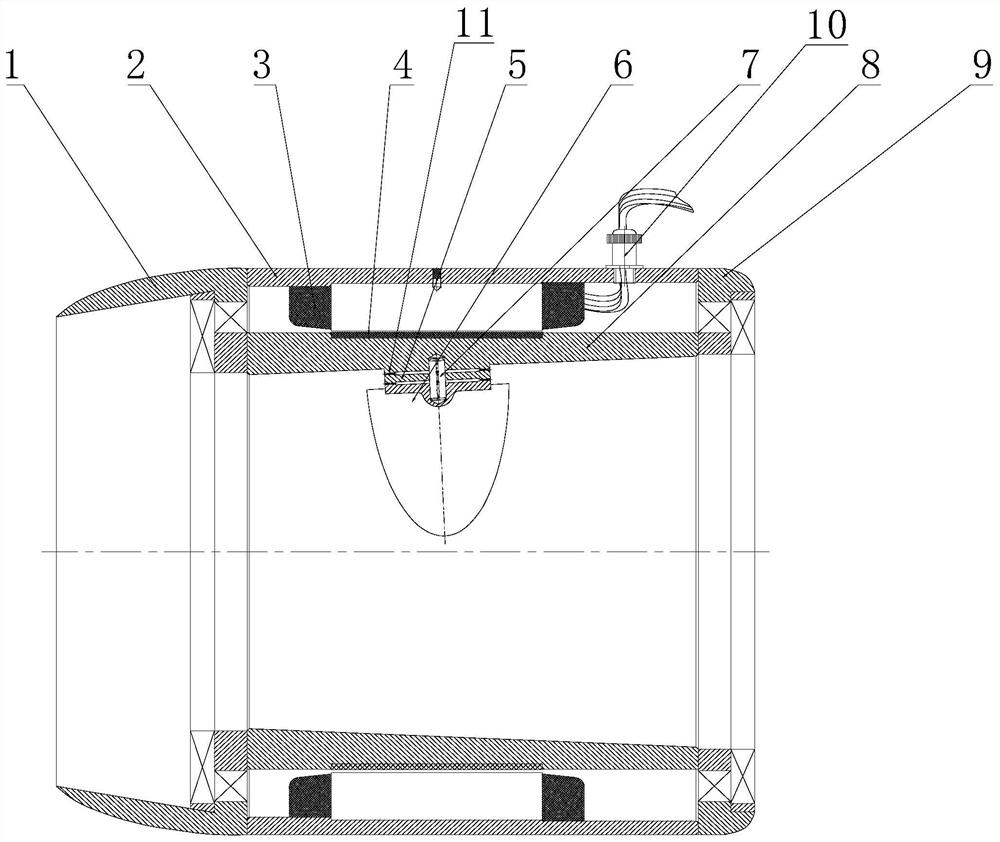

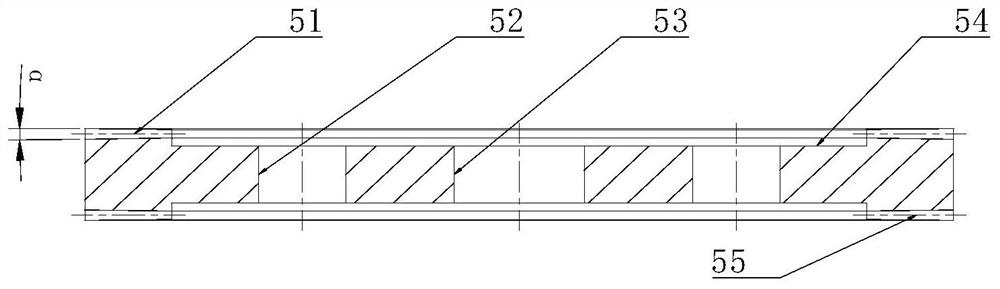

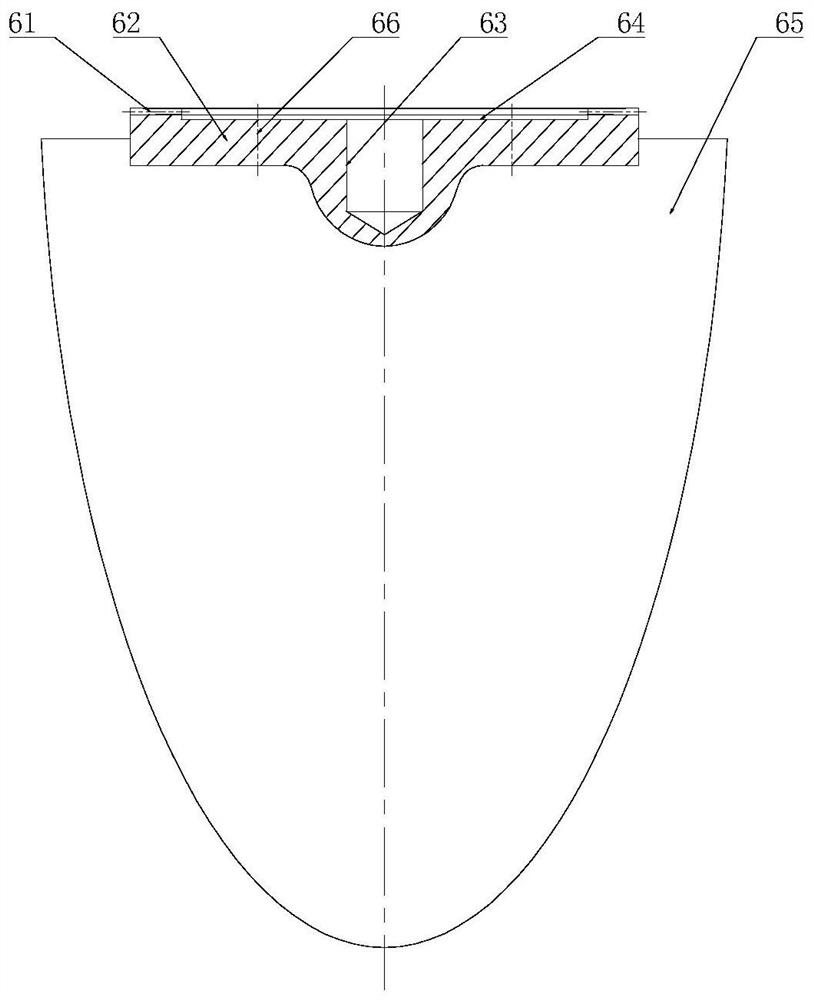

[0029] Such as Figure 1-4 As shown, a marine supercharged air hub propeller includes an air hub motor 10 and a front shroud 9 and a rear shroud 1 arranged at both ends of the hub air motor 10. The cylindrical guide box 8 in the shell 2, the motor stator 3 is provided on the inner wall of the shell 2, and the motor rotor 4 is provided on the outer wall of the guide box 8;

[0030] The inner hole of the diversion box 8 is conical, and the diameter of the hole gradually decreases along the direction close to the rear shroud 1; its taper is 6°. On the inner wall of the diversion letter 8, there are not less than three clutch seats 11 evenly distributed around the central axis; the clutch seat 11 is provided with a clutch ring gear whose center line is parallel to the radial direction of the diversion letter 8, and the clutch teeth on the clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com