Electrostatic coating method and electrostatic coating apparatus

A technology of electrostatic coating and coating equipment, which is applied in the direction of liquid spraying equipment, electrostatic spraying devices, coatings, etc., can solve the problems of difficult adaptation, unevenness, and achieve the effect of smoothness improvement and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

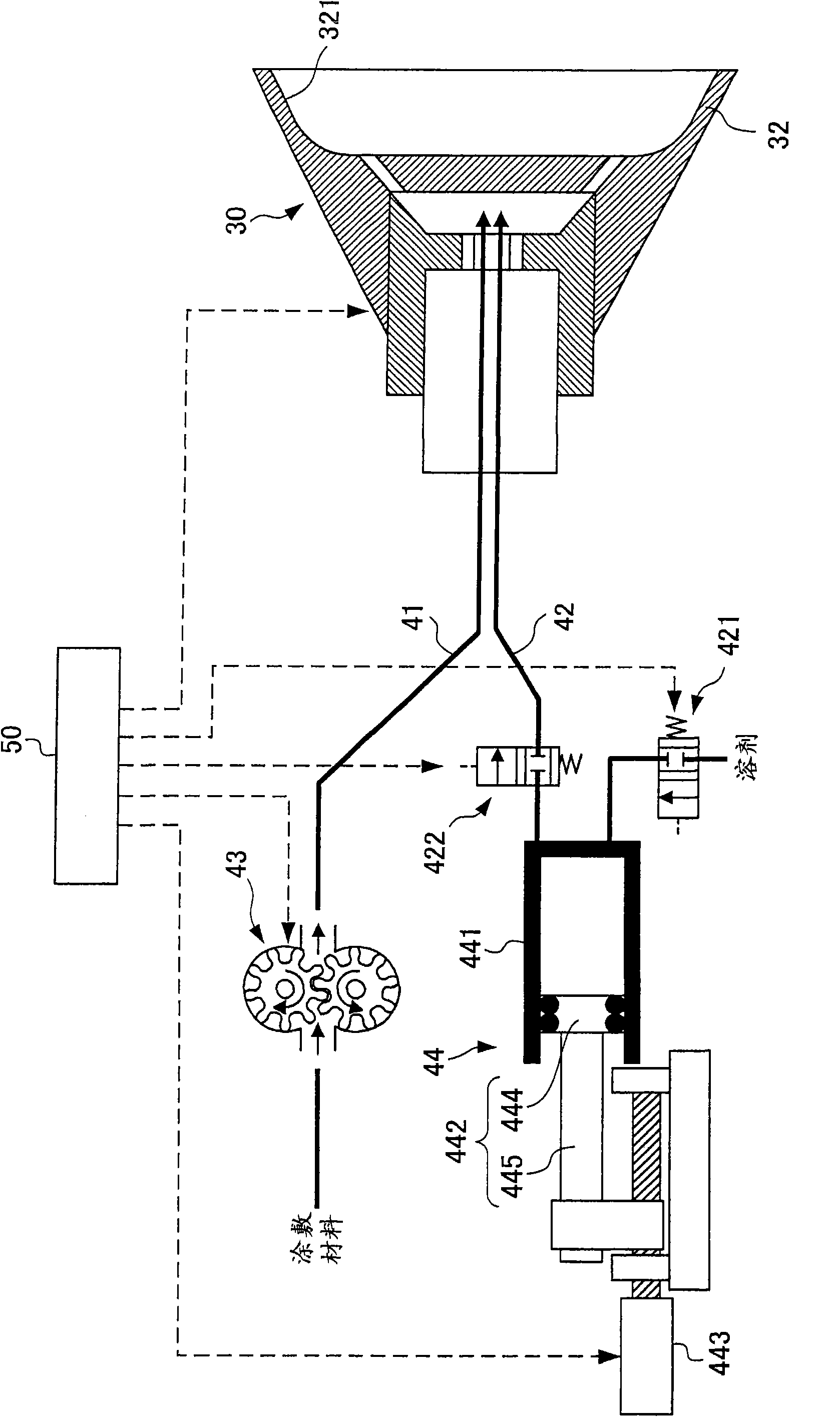

[0062] A coating material and a solvent were supplied to the varnish coating equipment as described above, and the relationship among the ratio of the solvent to the coating material, the NV value, and the LW value was investigated.

[0063] Figure 10 is a view showing the relationship between the number of revolutions of the rotary spray head and the NV value in the first embodiment. Figure 11 is a view showing the relationship between the number of revolutions of the rotary spray head and the LW value in the first embodiment. exist Figure 11 In , LW (Long Wave) is an index indicating the smoothness of the coated film measured by a measuring instrument called Wavescan (manufactured by BYK Gardner GmbH). Specifically, the surface of the coated film was irradiated with a laser beam from Wavescan, the intensity of reflected light of the surface of the coated film was detected and the optical profile of the surface of the coated film was detected. This optical profile is th...

no. 1 approach

[0068] In addition, the present invention is not limited to the first embodiment, and changes, improvements, and the like within a scope capable of achieving the object of the present invention are included in the present invention. For example, in the first embodiment, an electrostatic coating method is applied to the varnish coating equipment 10 . However, the present invention is not limited thereto. That is to say, the present invention can be applied to intermediate coating equipment, and can be applied to equipment other than primer coating equipment in surface coating equipment, such as protective varnish coating equipment (advanced varnish coating performed on top of varnish coating) apply). Furthermore, the present invention can be applied to one of these equipments, and can be applied to multiple equipments.

[0069] In addition, in the first embodiment, in the varnish application equipment 10, internal mixing with a gun tip is employed. However, the present inven...

Embodiment 2 and comparative example 2

[0080] A coating material and a solvent were supplied to the varnish coating equipment of the second embodiment, and the relationship between the ratio of the solvent to the coating material and the NV value or LW value was investigated.

[0081] Figure 12 is a view showing the relationship between the discharge amount of the rotary spray head and the NV value when the number of revolutions of the rotary spray head is constant in the second embodiment. Figure 13 is a view showing the relationship between the discharge amount of the rotary spray head and the LW value when the number of revolutions of the rotary spray head is constant in the second embodiment.

[0082] In the case of normal coating (standard condition) in which the supply amount of the coating material supplied to the rotary spray head is not reduced, as the discharge amount changes from 1 4 reduce to l 1 , the NV value becomes higher. Here, when the emission is l 3 When , the NV value falls within the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com