Power storage control apparatus and method of electric vehicle

A storage control and electric vehicle technology, applied in battery/fuel cell control devices, electric vehicles, DC motor traction, etc., can solve the problem of deteriorating stop position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

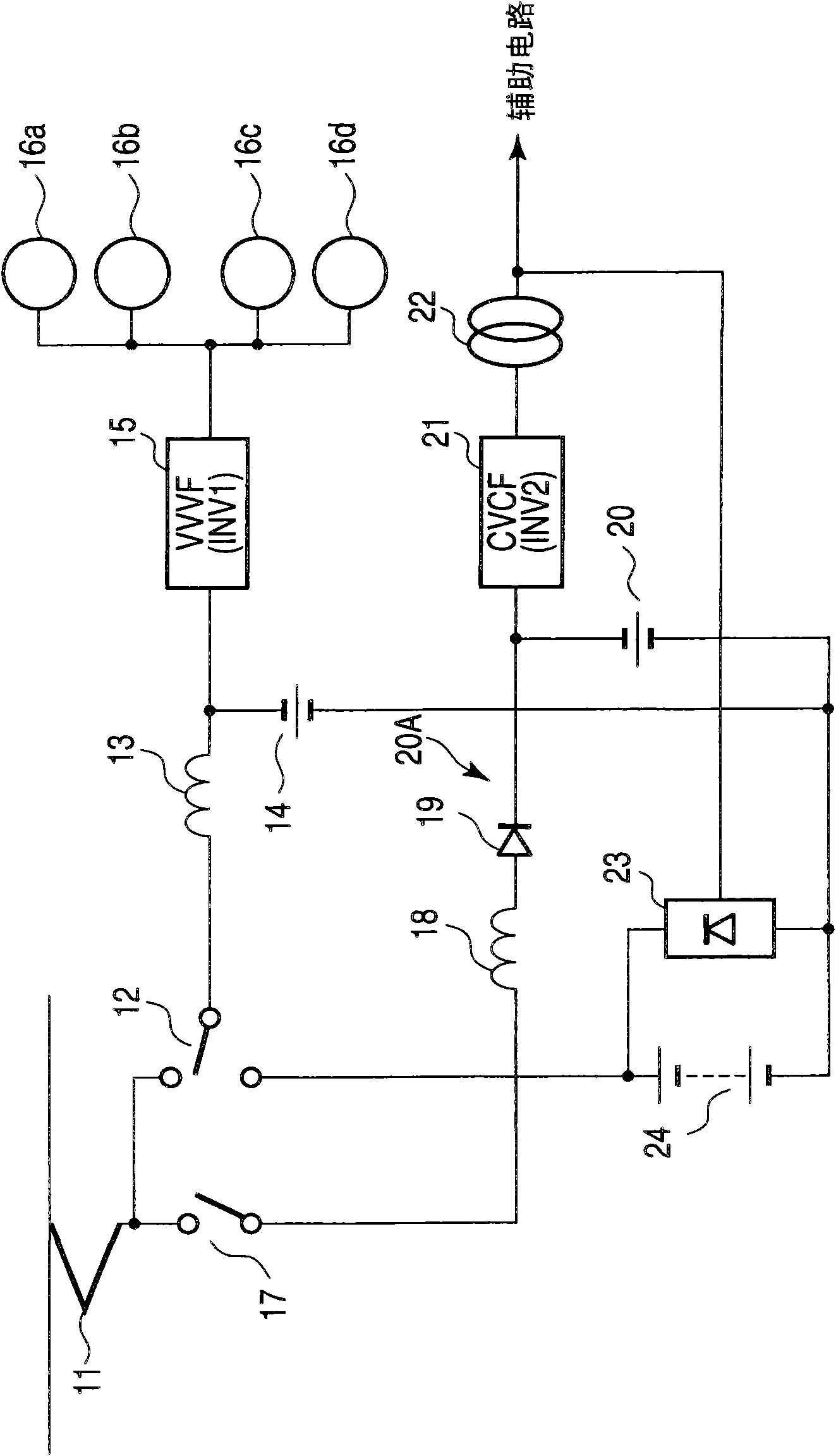

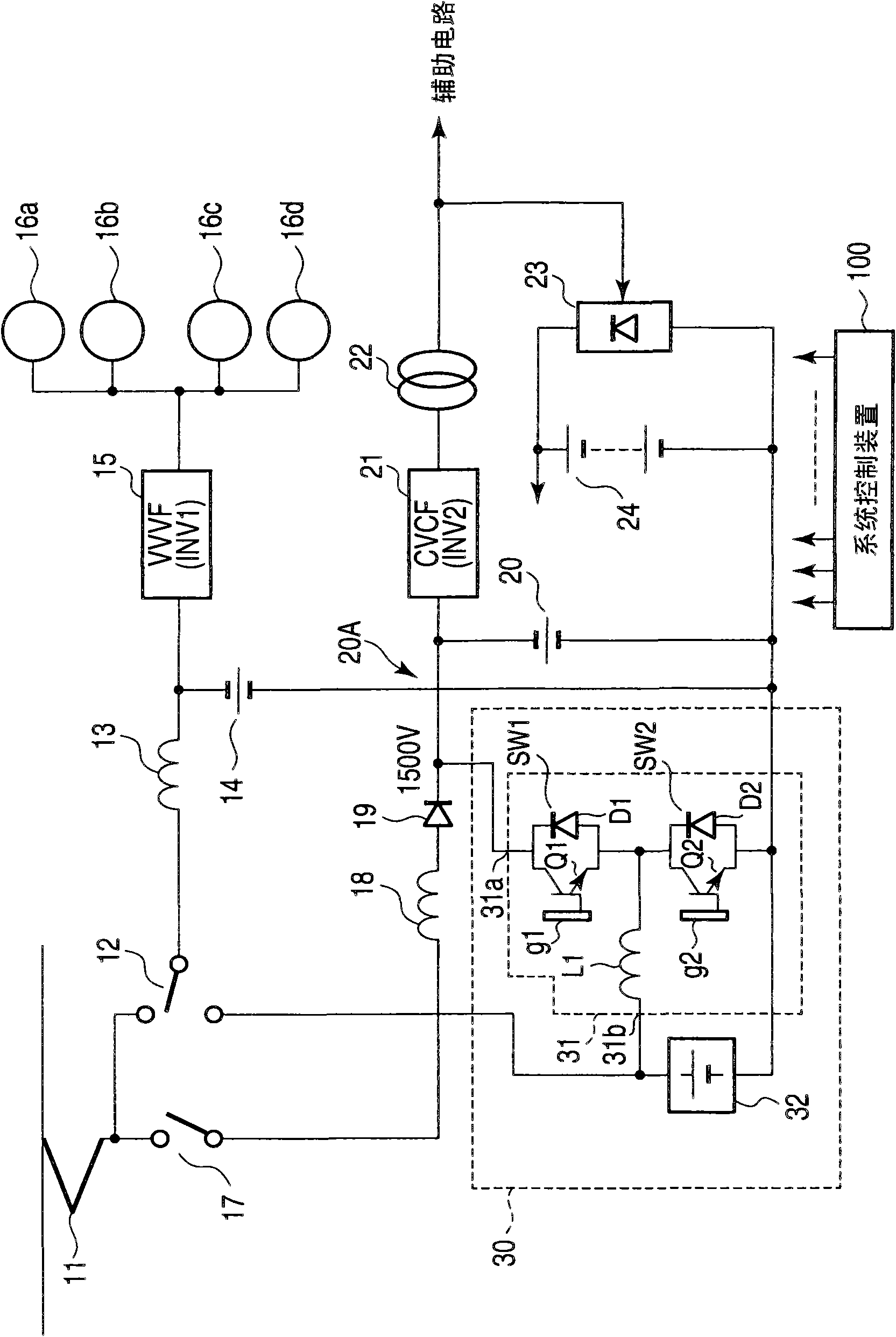

[0023] Embodiments of the present invention will now be specifically described. First refer to figure 1 The generalized circuit of the electric vehicle circuit shown in , is used to explain the driving control method currently used, for example, by trolleybuses capable of running on battery power.

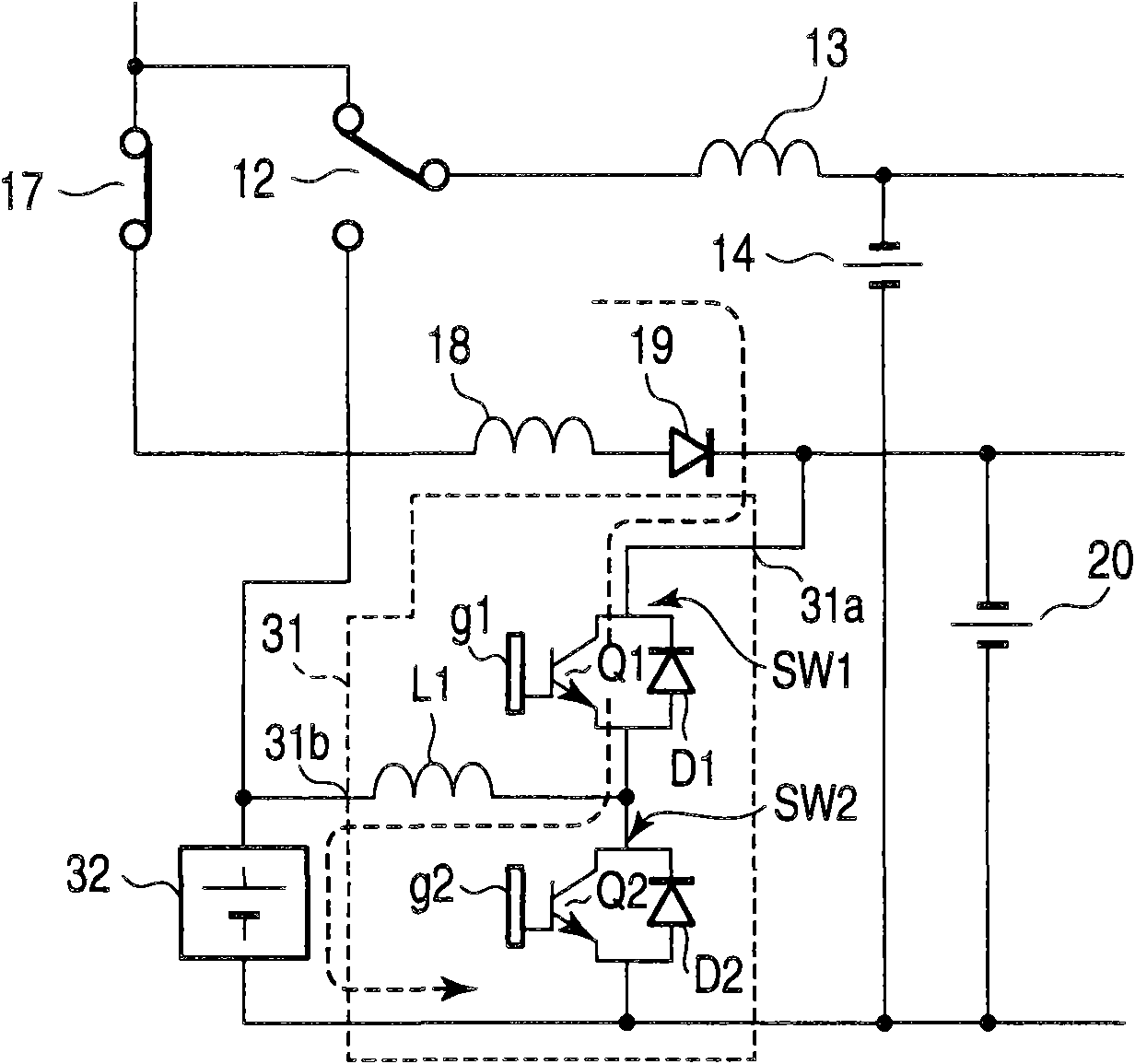

[0024] The current collector 11 , which collects power from the outside such as the electric vehicle line, supplies its output power to the contactors 12 and 17 . In a normal state, the power that has passed through the contactor 12 is filtered by the reactor 13 and the capacitor 14 and supplied to a variable voltage variable frequency (VVVF) inverter 15 . In a normal state, power that has passed through the contactor 17 is supplied to a constant voltage constant frequency (CVCF) inverter 21 via an input circuit 20A including a reactor 18 , a blocking diode 19 and a capacitor 20 . Reactor 18 and capacitor 20 form a filter.

[0025] The output from the VVVF inverter 15 is supplie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com