Anchor design of pre-stressed carbon fiber reinforced plastic rib group

A carbon fiber and prestressed technology, applied to structural elements, building components, building reinforcements, etc., can solve problems such as insufficient strength, difficult anchorage design, weak shear and compression resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

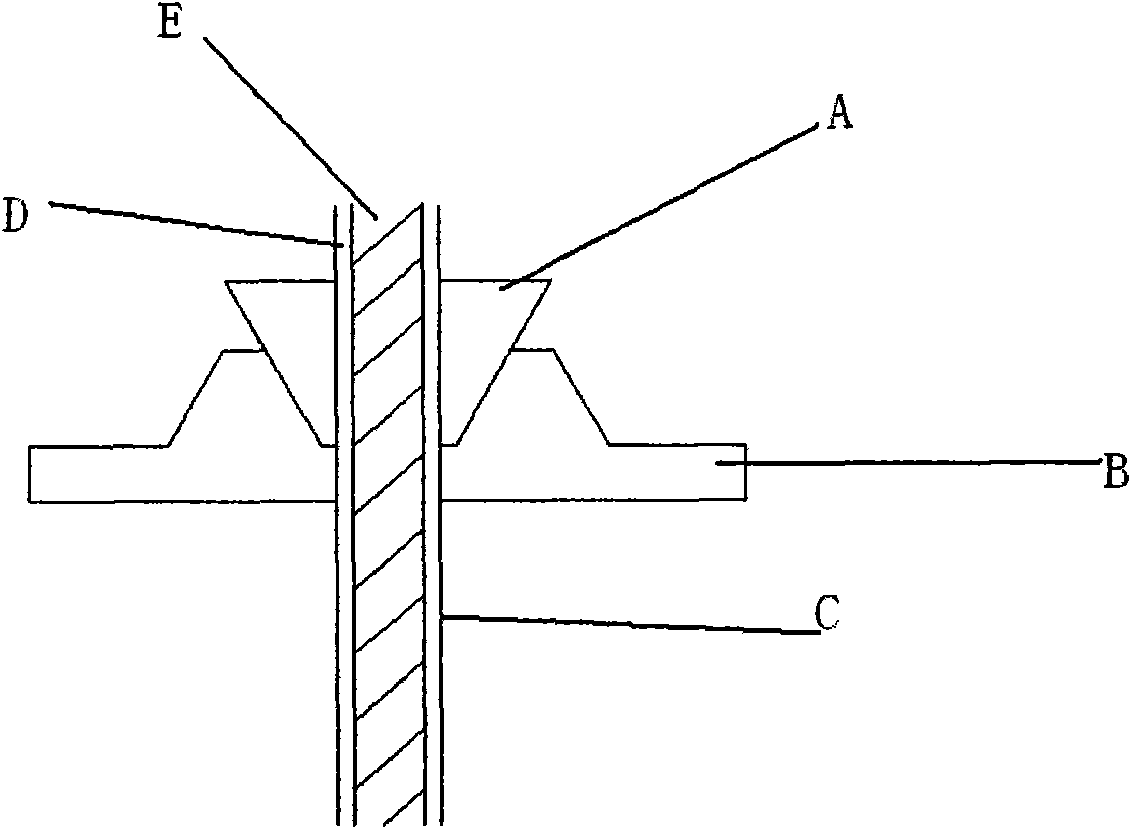

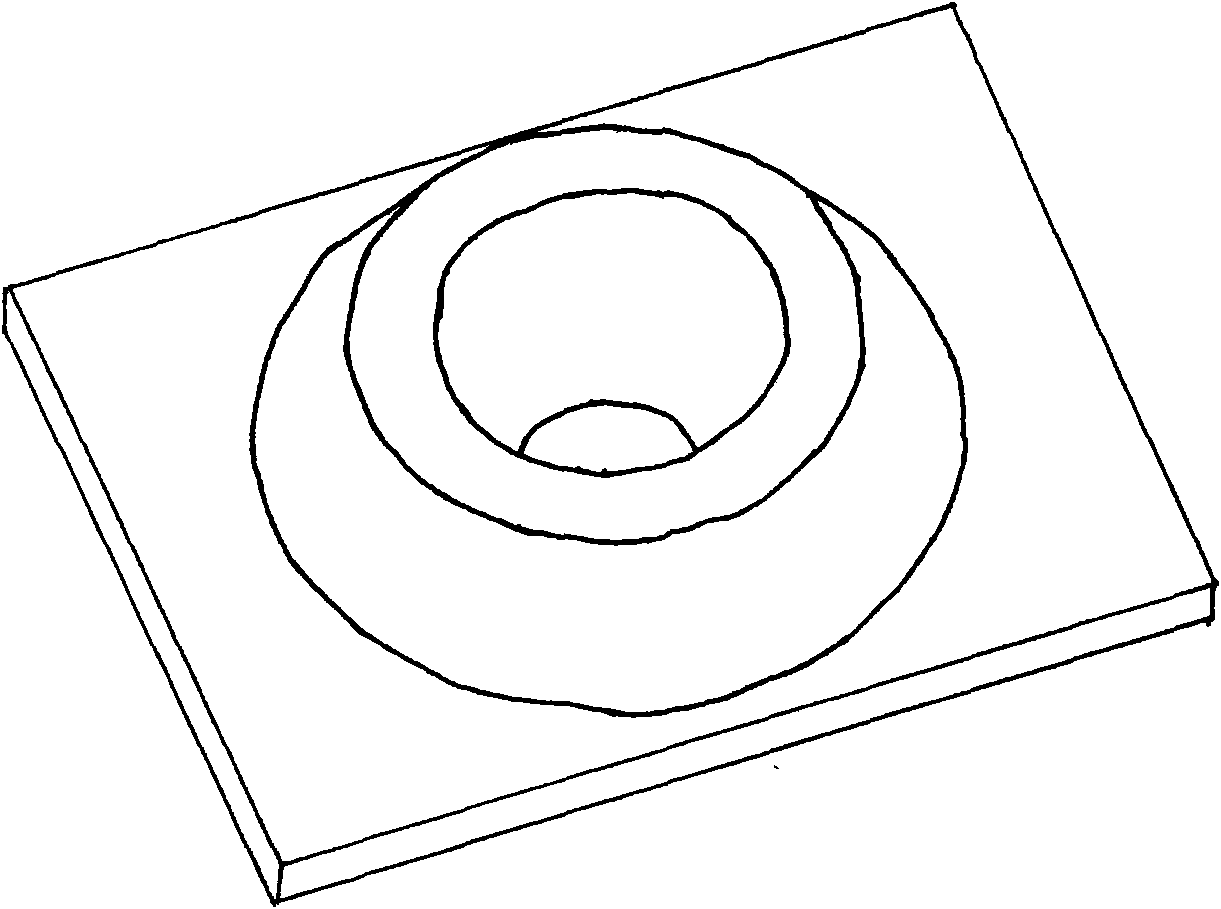

[0014] First, put the CFRP bars into the sleeve, pour epoxy resin, and mix epoxy sand:

[0015] Then, after a certain strength is formed, the sleeve is rotated into the cone plug;

[0016] After that, put the cone plug into the anchor plate;

[0017] Then, after a certain strength is formed, use a jack at the other end of the anchorage to stretch the CFRP tendon with a relatively small force, and stretch it to the design strength when the strength is fully formed;

[0018] Then, use the same anchor at the tension end, and fix the anchor at the end of the concrete beam;

[0019] Finally, install the anchors in other anchor holes.

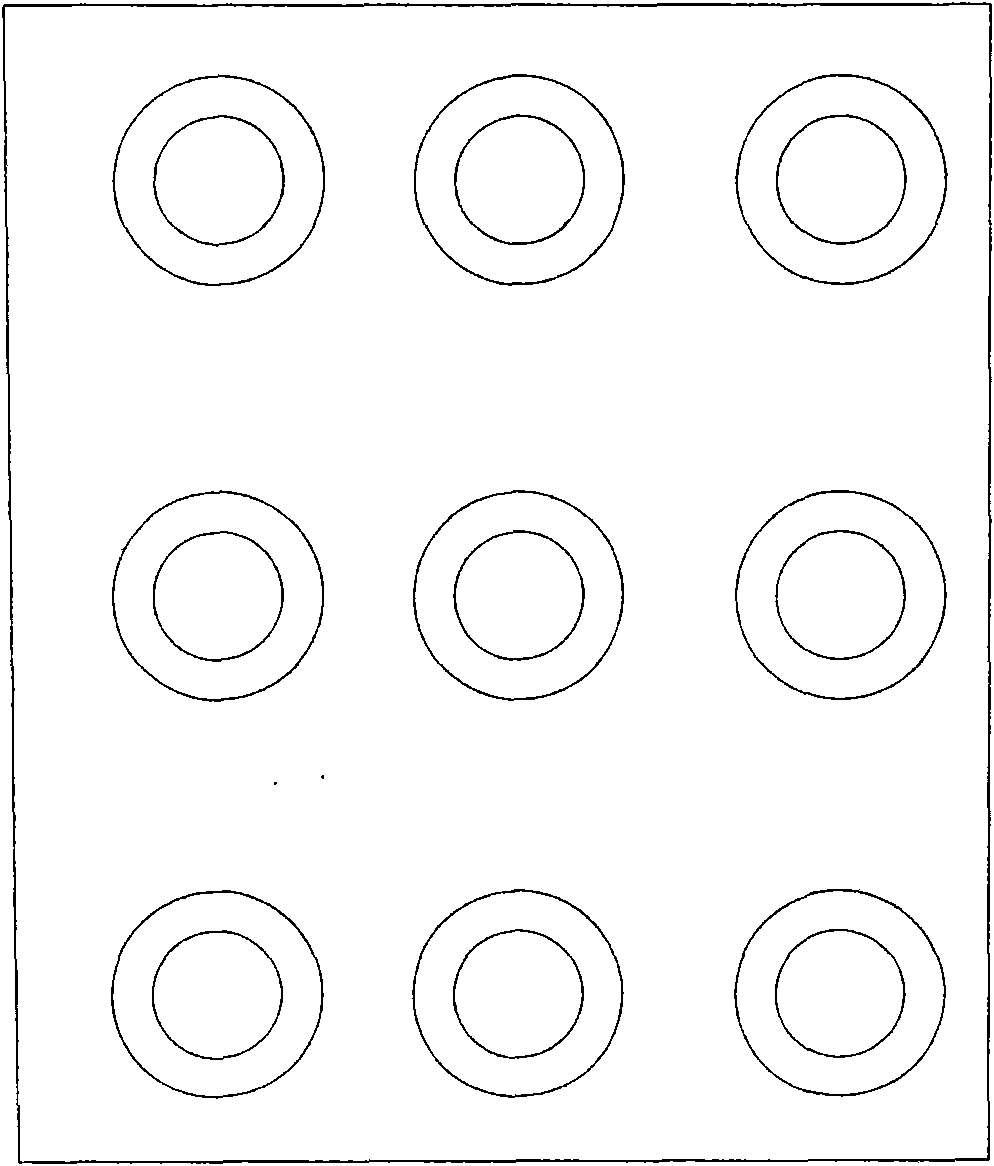

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com