Embedded shock-absorption steel frame for seismic hardening

A steel frame and built-in technology, which is applied in the direction of earthquake resistance, building maintenance, pillars, etc., can solve the problems of reducing the internal space of buildings, affecting production and life, and affecting the use of functions, so as to reduce the demand for earthquake resistance and have a wide range of applications. Reduce the effect of earthquake action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

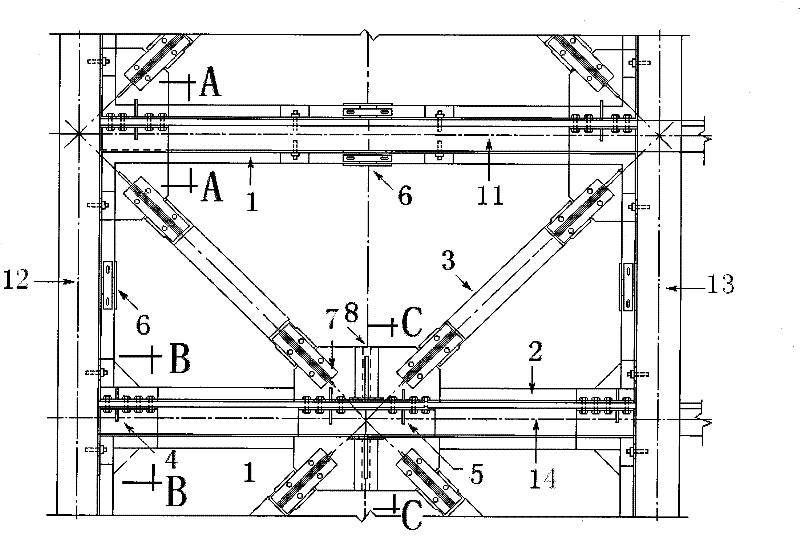

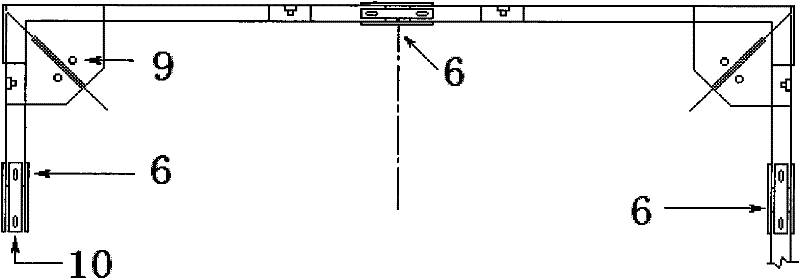

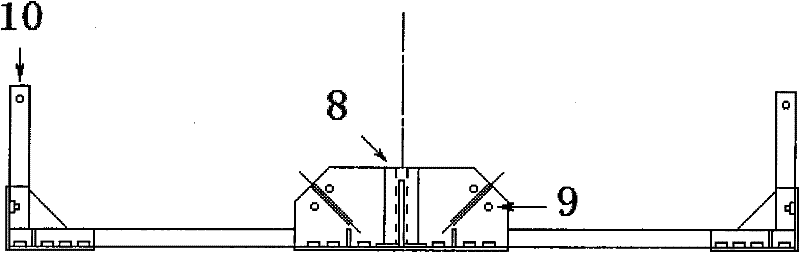

[0037] Such as figure 1 As shown, the shock-absorbing steel frame in this embodiment can be arranged on various floors of some spans of the building, including the upper steel frame 1, the lower steel frame 2, the metal yield type damper 3 and the first connector 4 and the second Connector 5. Both the upper steel frame 1 and the lower steel frame 2 are in the shape of a "door", and they are connected to each other to form a rectangular frame. The four corners of the upper steel frame and the lower steel frame are fixedly connected to the beam through the first connecting piece 4 respectively, and the first connecting piece 4 is composed of or Shaped bottom cover 15 and a cover plate 16 covering the floor, the cross-sectional shape of the bottom cover is the same as that of the upper beam, the bottom cover covers the surface of the upper beam, the cover plate is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com