Special bearing for coal mining machine

A bearing and coal machine technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as shortening the service life of bearings, early fatigue spalling of bearings, and affecting bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

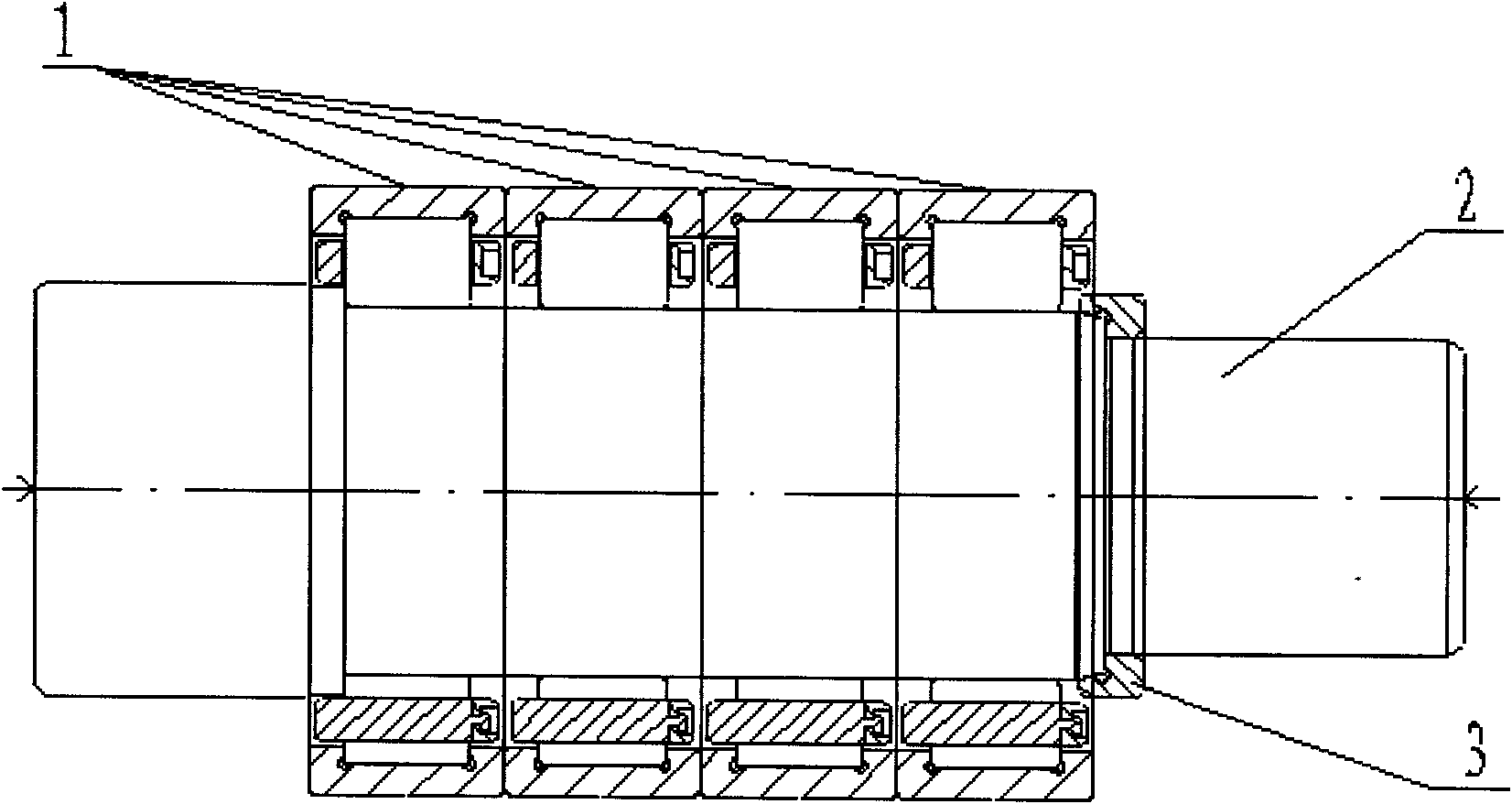

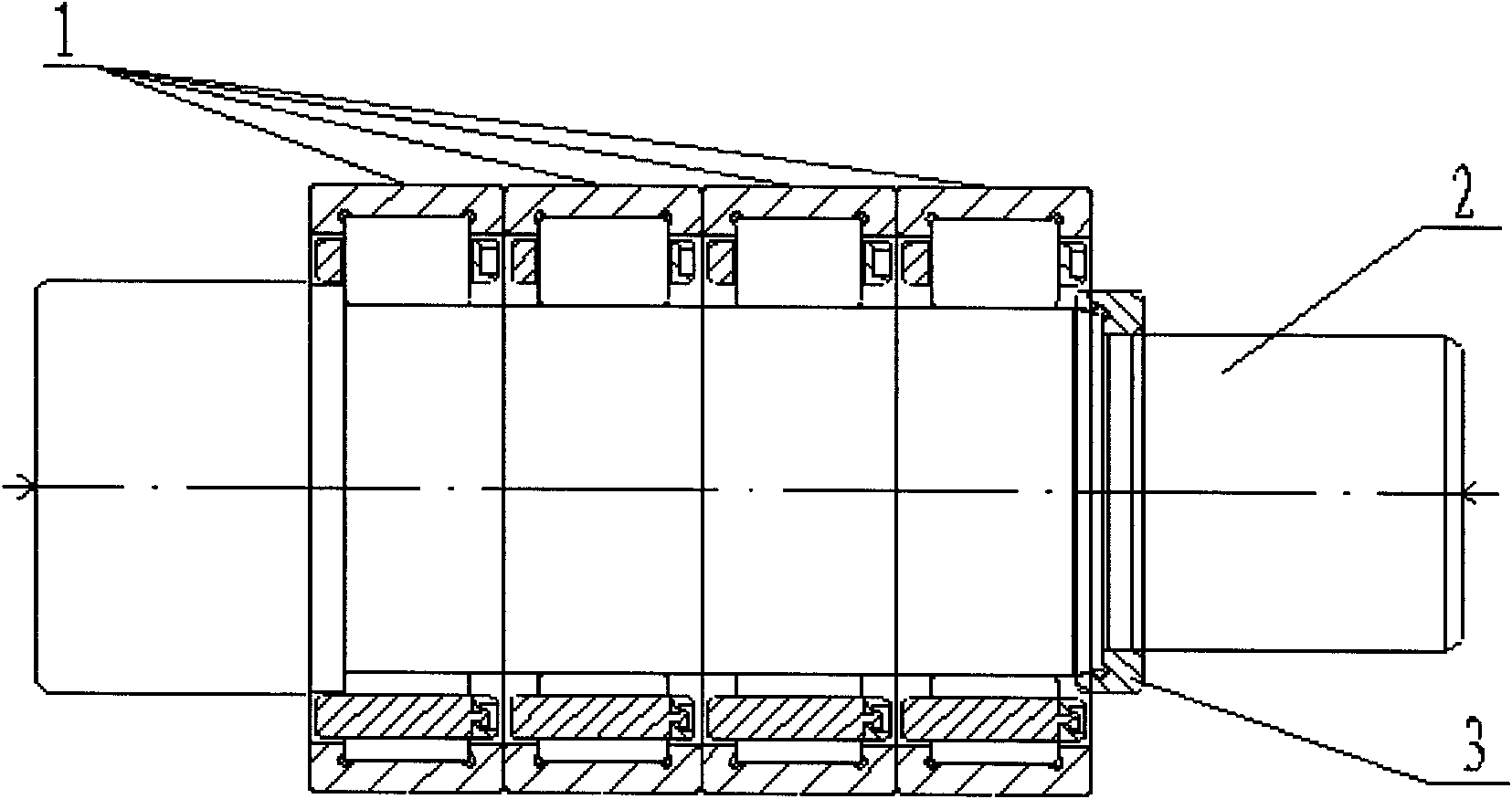

[0013] combine figure 1 , this embodiment includes a bearing 1, a mandrel 2 and a beveled retaining ring 3. The bearing 1 adopts a single-row cylindrical roller bearing with an outer ring having double ribs, which is inseparable from the roller, has no inner ring and uses a copper cage, and is used together. This structure saves radial space; the mandrel 2 adopts a stepped structure for easy positioning, which is convenient for axial positioning; four sets of single-row cylindrical roller bearings are installed on the second step of the stepped shaft in cooperation with each other, and the bearing and the mandrel adopt a transition fit Mode; the oblique retaining ring 3 is designed with a slope, installed on the third step of the stepped shaft, and acts as a limiter for the entire bearing unit. The entire bearing unit has a compact structure and is i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap