OLED monitor and packaging method thereof

An encapsulation method and display technology, which can be applied to instruments, identification devices, etc., can solve the problems of increasing the distance between the substrate 1 and the back cover 2, increasing the thickness of the display, and increasing the weight of the display, so as to achieve the effect of reducing the weight and reducing the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

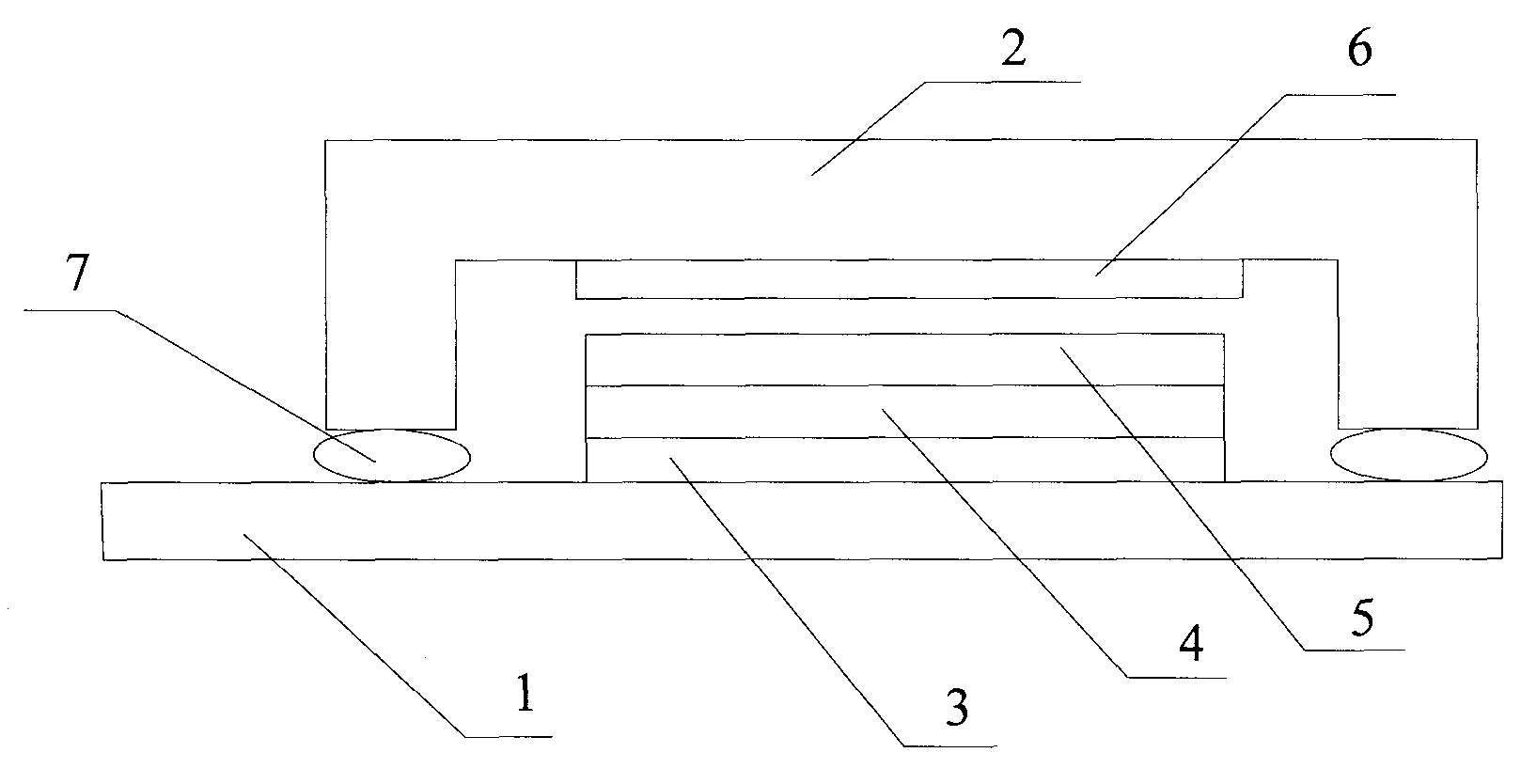

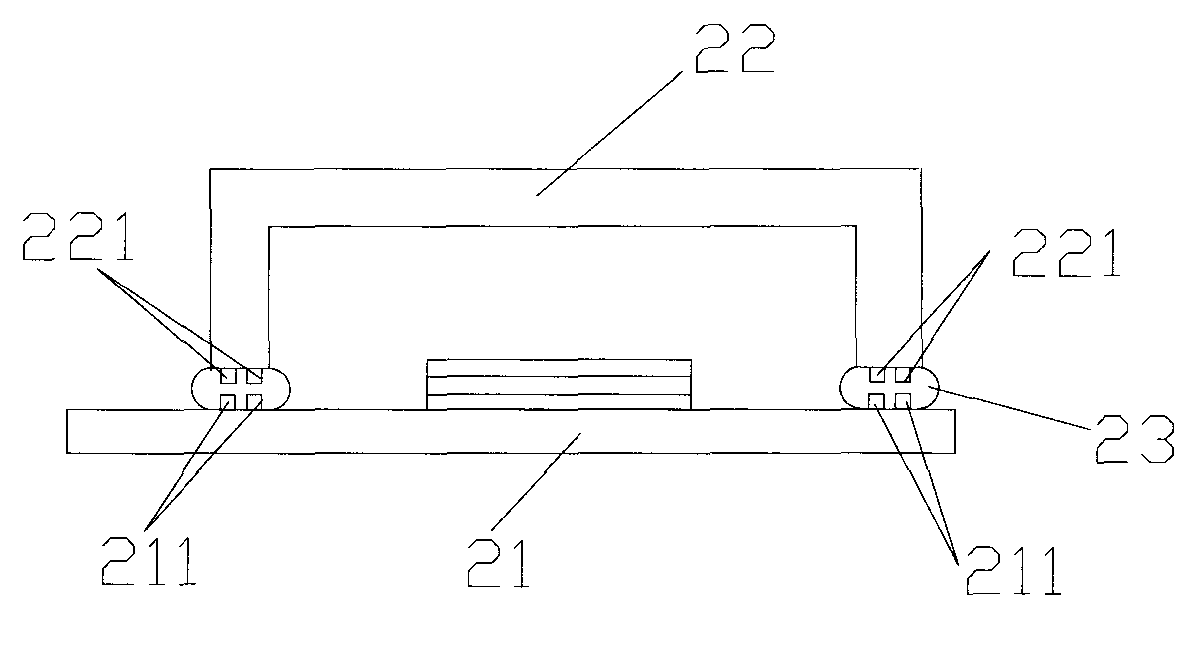

[0040] Such as figure 2 Shown is a cross-sectional view of the OLED display in this embodiment. The display includes a substrate 21 and a back cover 22 that are bonded to each other. The substrate 21 in the bonding area has a first protrusion 211 facing the back cover 22, and the back cover 22 has The second protrusions 221 facing the substrate 21, the first protrusions 211 and the second protrusions 221 correspond to each other, and are wrapped in the packaging glue 23.

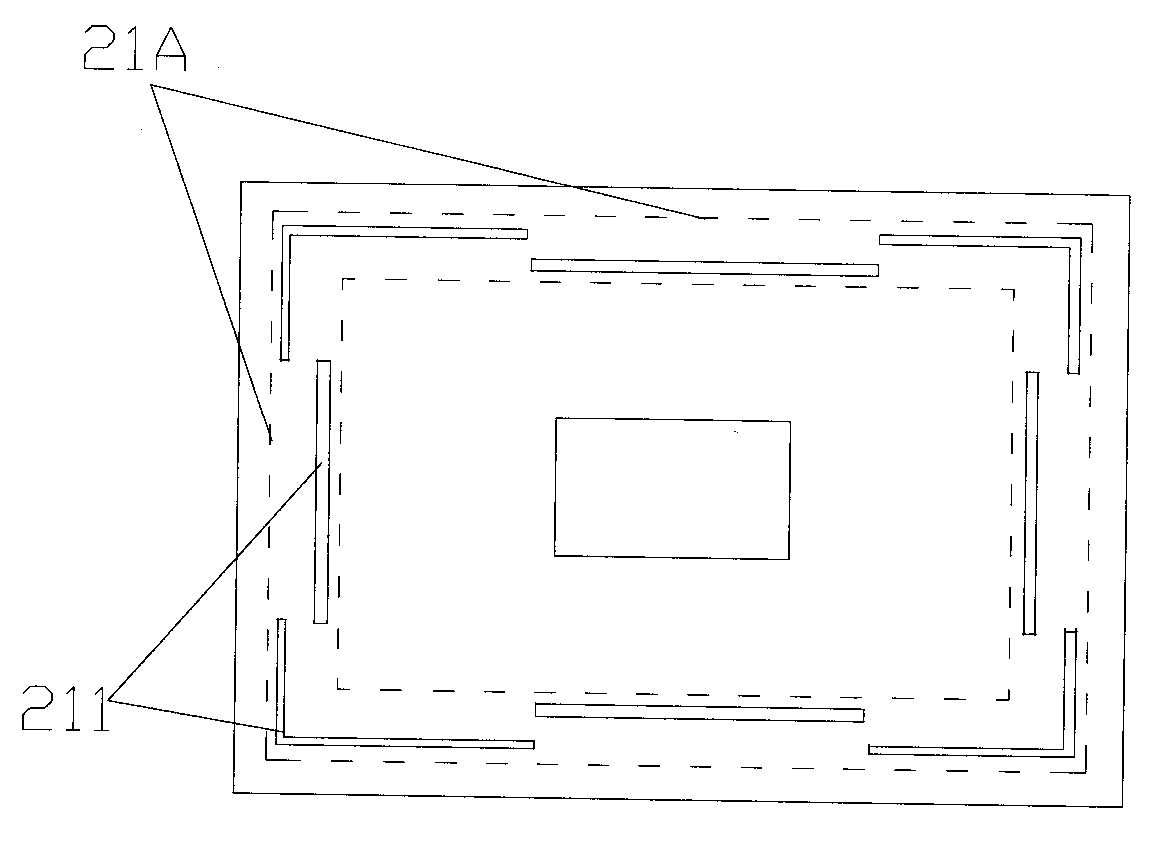

[0041] Such as image 3 Shown in this embodiment is the top view of the display substrate 21. In the center is the stacked cathode, organic functional layer and anode. Near the edge of the substrate 21 is the annular bonding area 21A of the substrate 21 and the back cover 22. It has a square ring shape. In this area, two incomplete first protrusions 211 are arranged along the square ring. The first protrusions 211 on the outer ring are arranged at the four corners of the square ring, and the first protrusions 2...

Embodiment 2

[0045] Such as Figure 4 Shown is a cross-sectional view of the OLED display in the second embodiment. The display includes a substrate 41 and a back cover 42 that are bonded to each other. The substrate 41 in the bonding area has a first protrusion 411 facing the back cover 42, and the back cover 42 There are second protrusions 421 facing the substrate 41, and the first protrusions 411 and the second protrusions 421 are distributed alternately and are wrapped in the packaging glue 43.

[0046] Such as Figure 5 Shown is a top view of the display substrate 41 in this embodiment. Located in the center is the stacked cathode, organic functional layer and anode. Near the edge of the substrate 41 is the annular bonding area 41A between the substrate 41 and the back cover 42. The ring is a square ring, of course, it can also be a circular ring. It has a ring shape, and two complete first protrusions 411 are arranged along a square ring in this area. Of course, the two first protrusion...

Embodiment 3

[0050] Such as Figure 7 Shown is a cross-sectional view of the OLED display in the third embodiment. The display includes a substrate 71 and a back cover 72 that are bonded to each other. The substrate 71 in the bonding area has a first protrusion 711 facing the back cover 72, and the back cover 72 There are second protrusions 721 facing the substrate 71, and the first protrusions 711 and the second protrusions 721 are alternately distributed with each other and are wrapped in the packaging glue 73.

[0051] The mechanism of the substrate in this embodiment is similar to that in the second embodiment, and will not be repeated here.

[0052] Such as Picture 8 Shown is a top view of the back cover 72 of the display in this embodiment. Near the edge of the back cover 72 is the annular bonding area 72A of the substrate 71 and the back cover 72, the bonding area 72A corresponds to the bonding area on the substrate 71, and three complete second circles are arranged in the bonding area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com