Positioning hole jig used in slow-silk thread cutting machine

A technology of positioning holes and wires, applied in positioning devices, manufacturing tools, clamping, etc., can solve the problems of wasting time and consumable costs, increasing the cost of consumables, and easy rusting of water iron plates, etc., achieving simple structure, small auxiliary man-hours, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

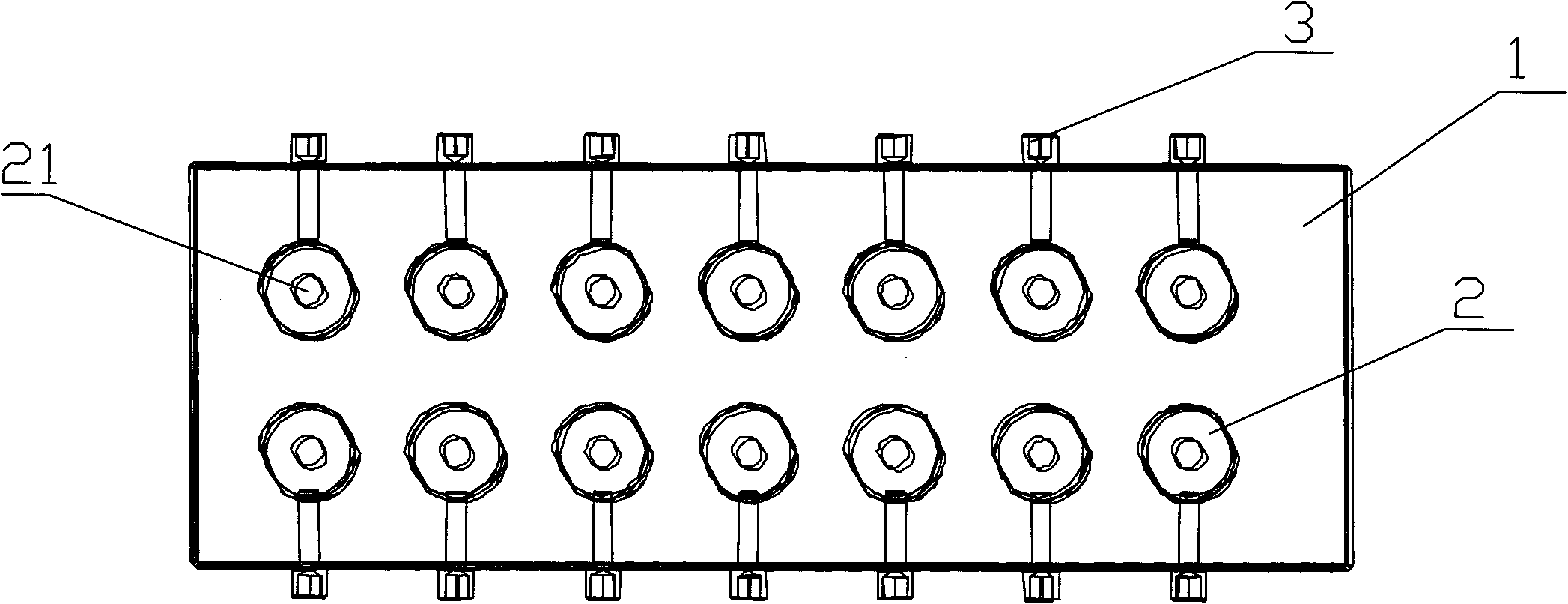

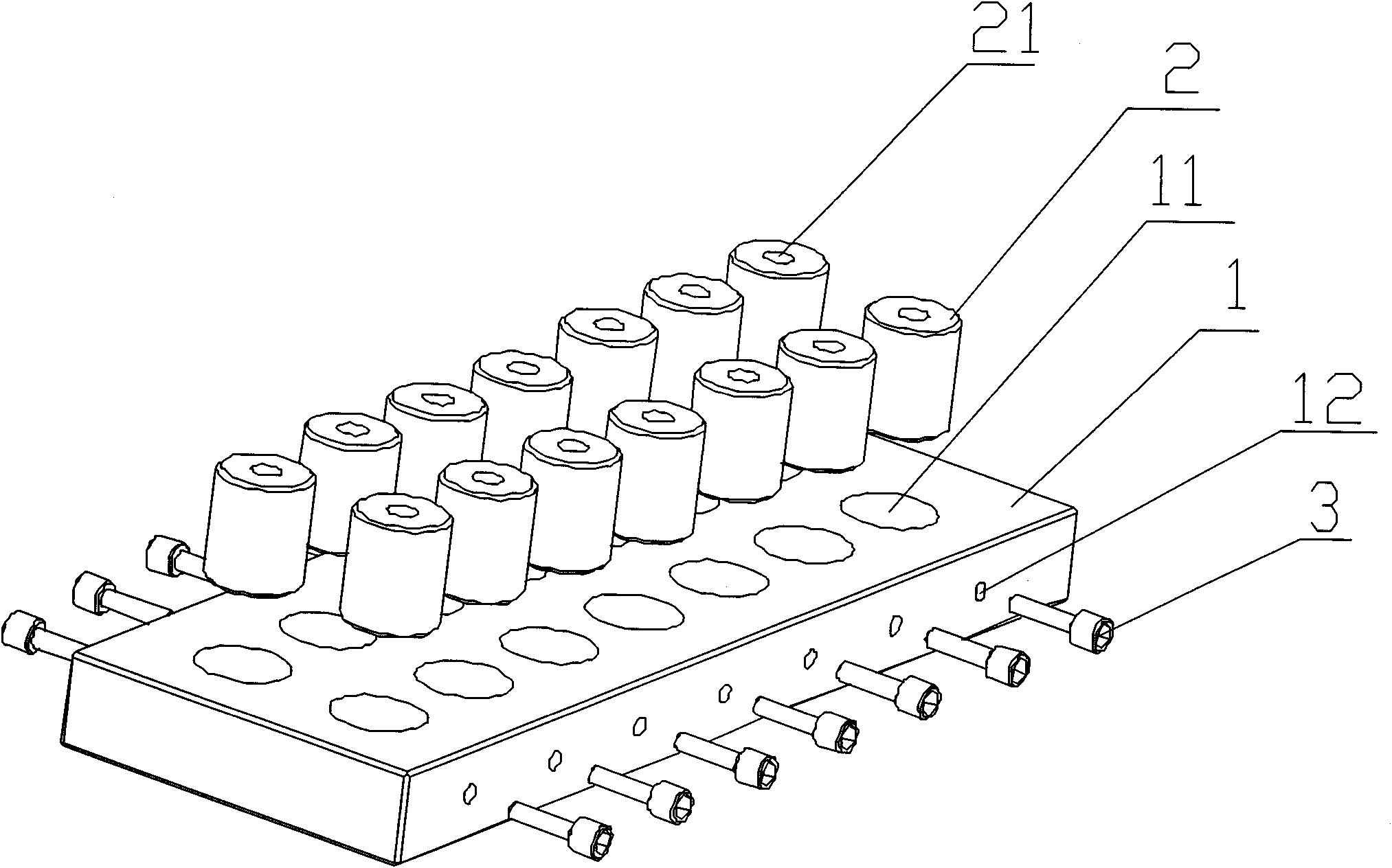

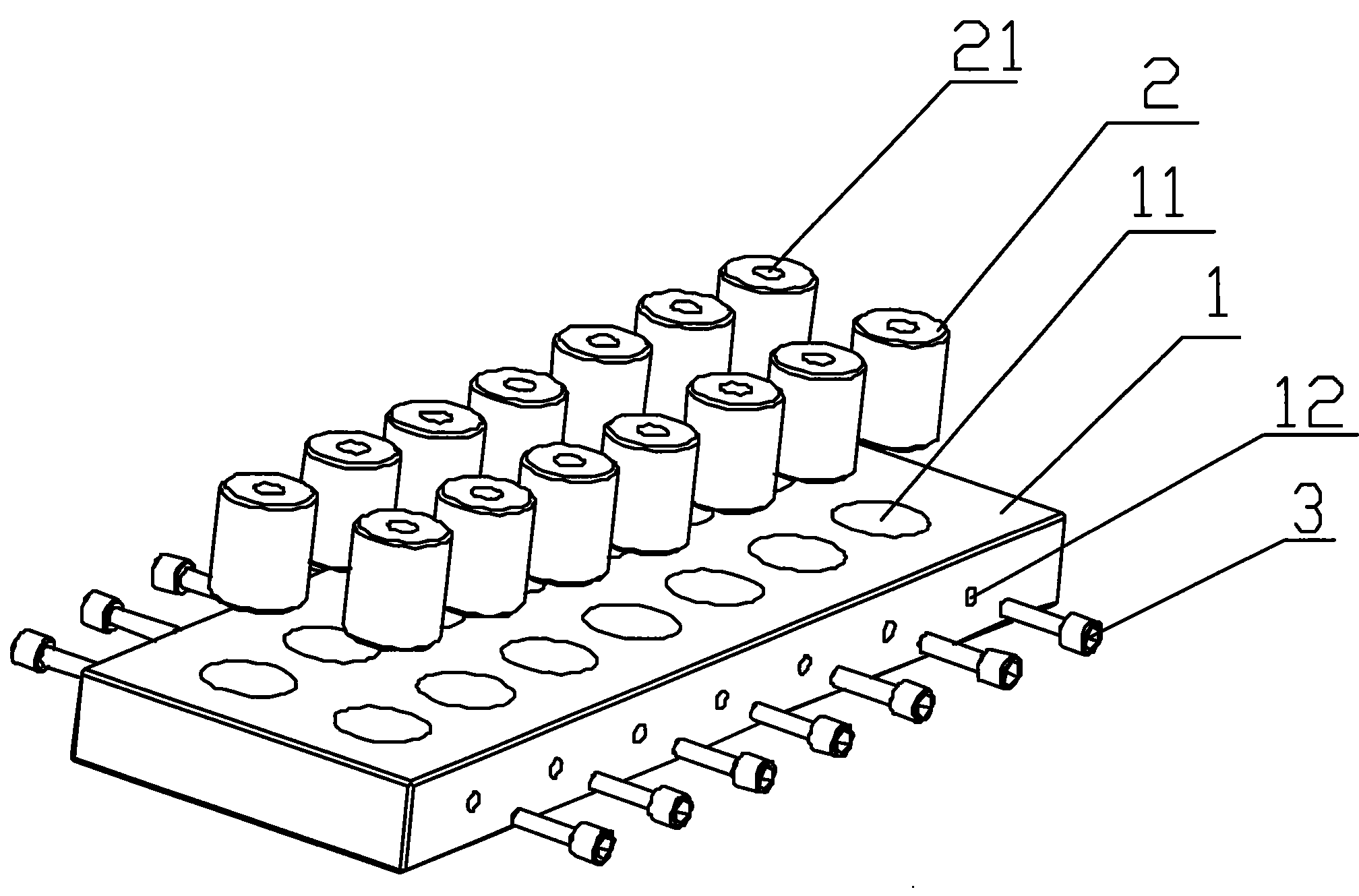

[0017] like figure 1 As shown, a positioning hole jig for wire cutting includes a positioning hole plate 1 and a set of tool setting bushing 2 and locking screw 3 matched with the positioning hole 11 on the positioning hole plate 1 . The positioning orifice plate 1 is made of stainless steel to prevent rusting in pure water, the processing medium of slow wire cutting.

[0018] In this example, see figure 2 , the positioning hole 11 on the positioning hole plate 1 is used to clamp the workpiece, and a tool setting bushing 2 is provided in each positioning hole 11, and the two sides of the positioning plate hole 1 are facing each positioning hole on it Each of the 11 places has a threaded hole 12 for screwing in the locking screw 3 to fix the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com