Open feed liquid self-sucking type inner cooling grinding wheel device for face grinding

A technology of face grinding and grinding wheel device, which is used in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., to achieve the effect of simple component structure and simple liquid supply method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

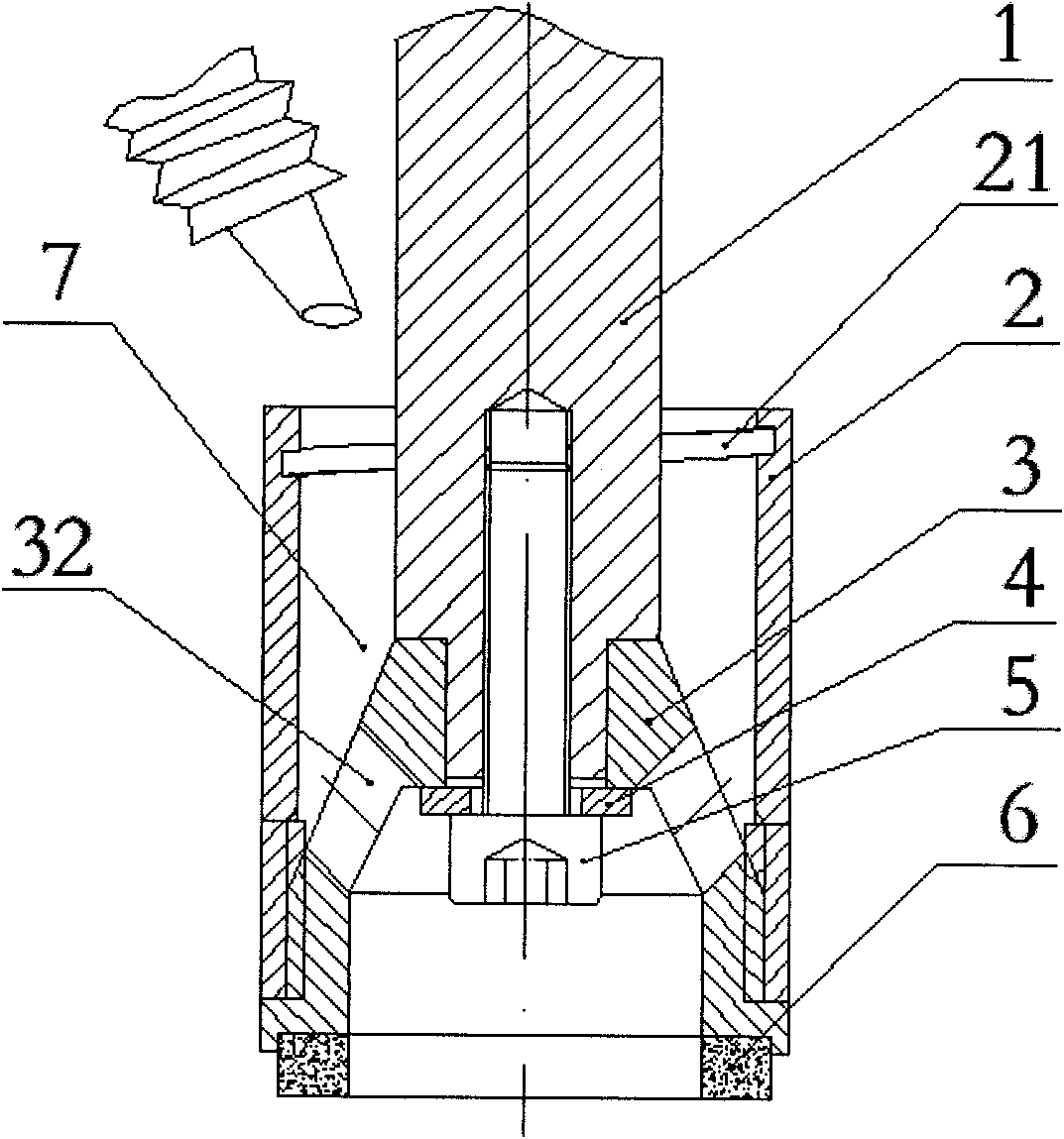

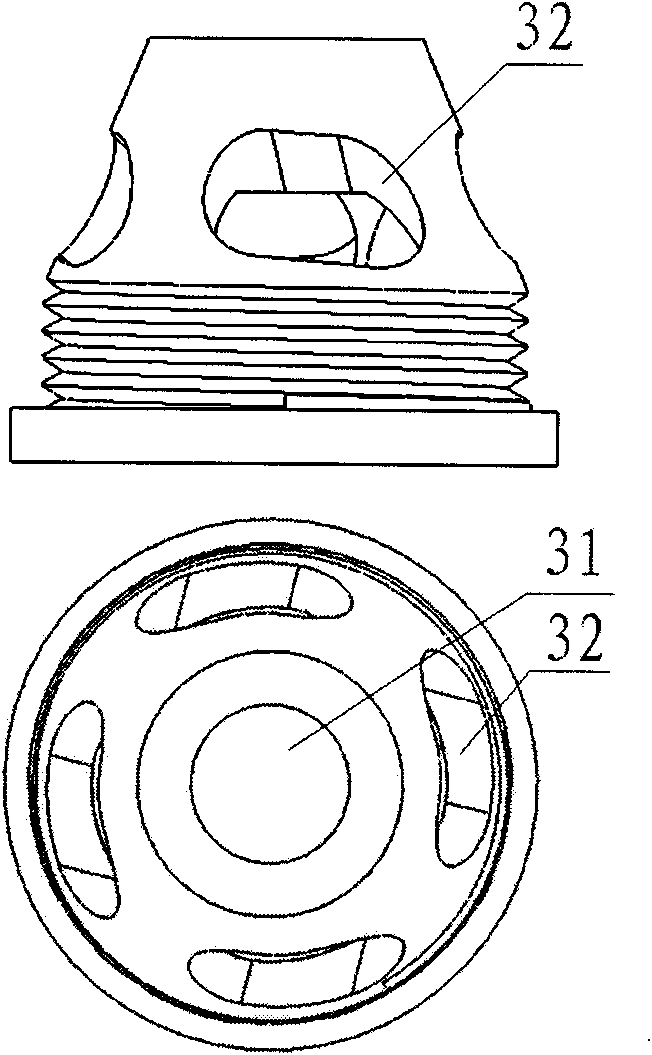

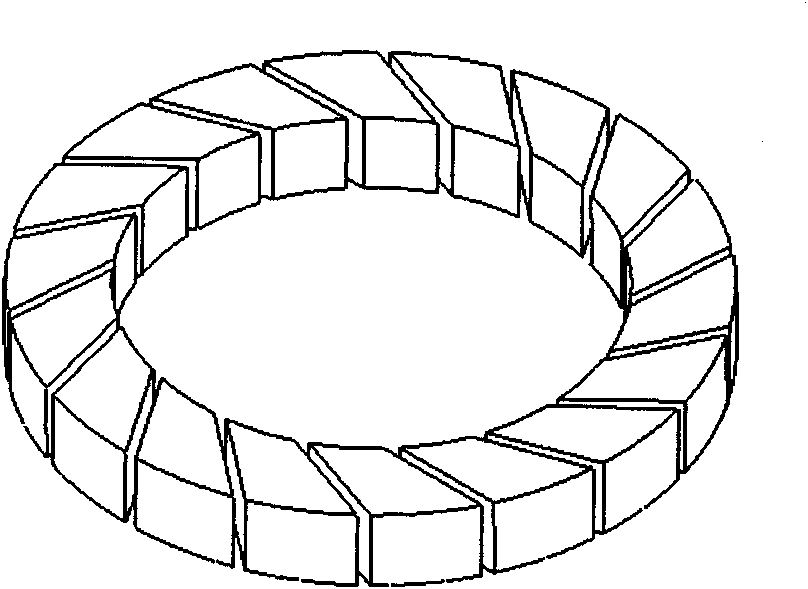

[0026] refer to figure 1 , figure 1 It is a full cross-sectional explanatory diagram of the overall assembly structure of the combined structure of the present invention, as shown in the figure, the device of the present invention includes a knife handle 1, a water collection sleeve 2, a grinding wheel base 3, a gasket 4, a screw 5, and a grinding wheel block 6 .

[0027] One end of the tool handle 1 is connected with the main shaft of the grinding machine, and under the action of the high-speed rotation of the main shaft, the whole grinding wheel is driven to rotate at high speed together. The water collecting sleeve 2 and the grinding wheel base 3 are connected by threads, and the cylindrical through hole 31 on the upper part of the grinding wheel base 3 cooperates with the cylindrical surface at the lower end of the handle for positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com