Electric screw driver having magnetic force overload protector

An overload protector and electric screwdriver technology, applied in screwdrivers, emergency protection circuit devices, electrical components, etc., can solve the problems of difficult manufacturing and assembly, high cost, noise generation, etc., and achieve extended service life, simple structure, and small impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

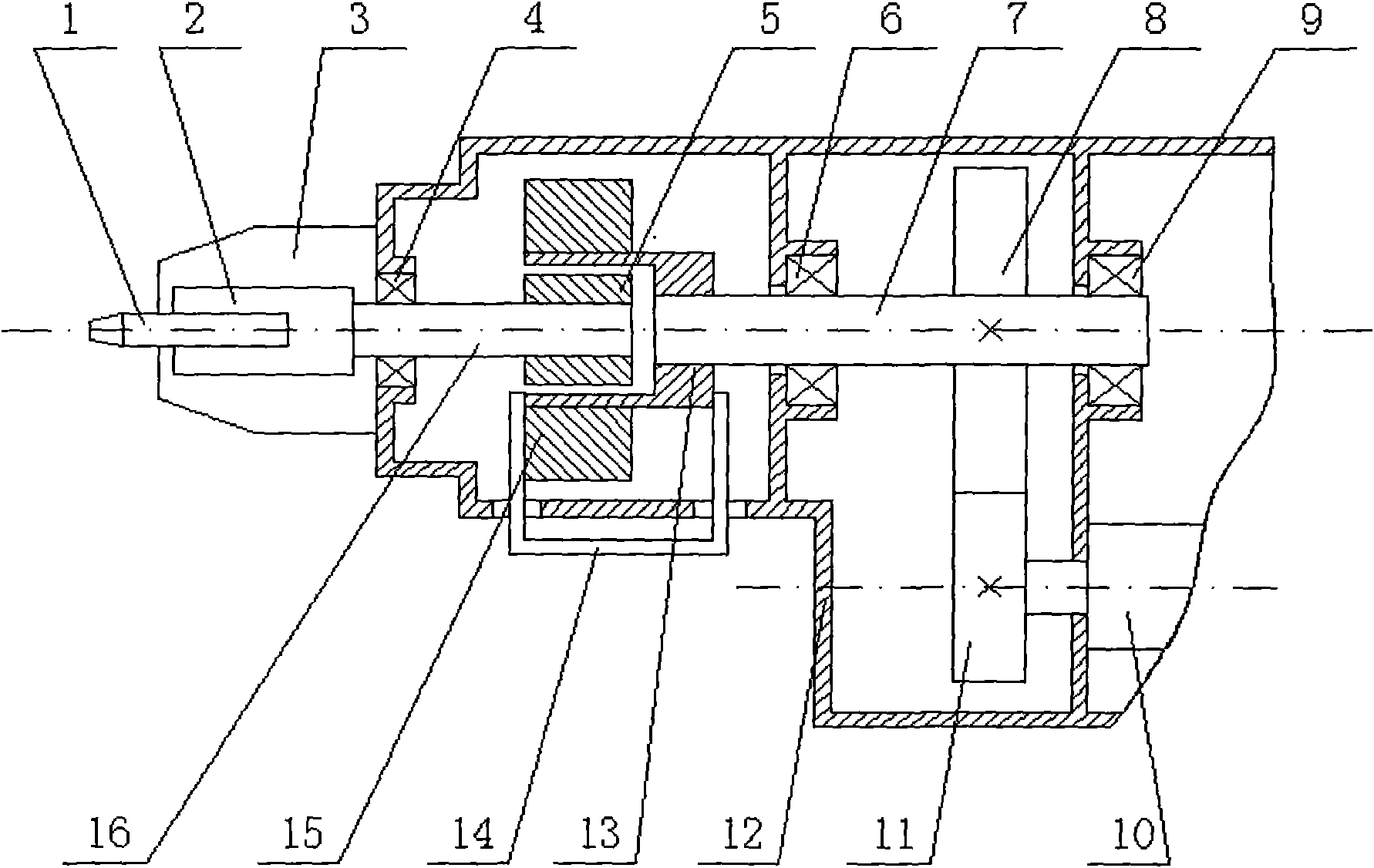

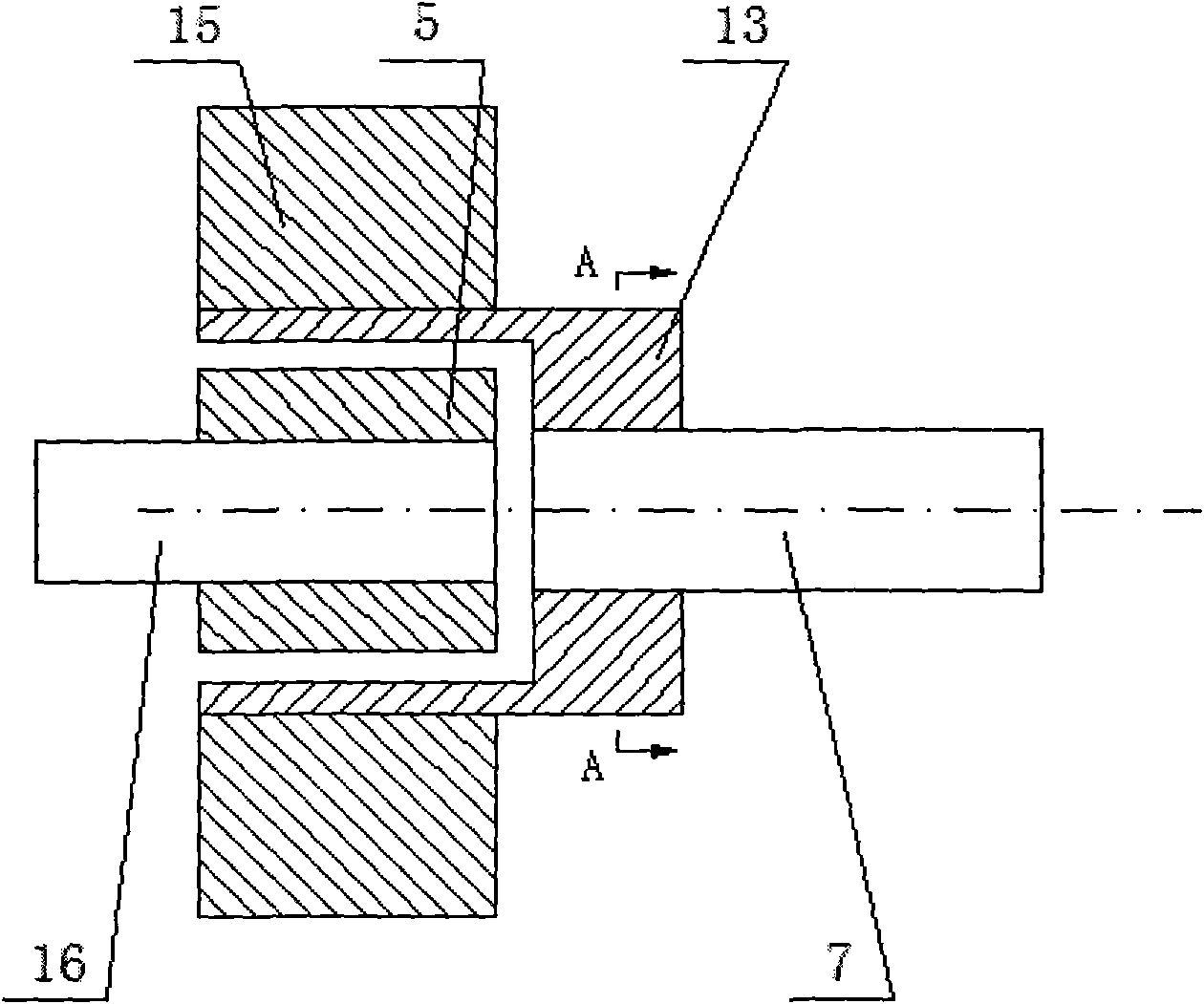

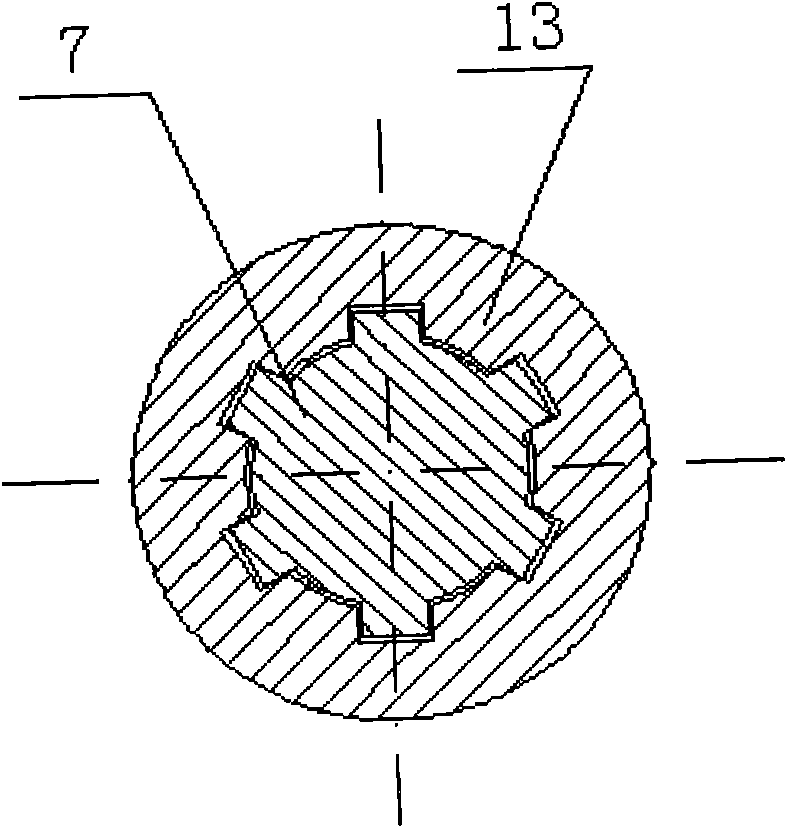

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a housing 12, a motion transmission mechanism composed of a motor 10, a motor gear 11, a drive shaft gear 8 and a drive shaft 7, an output shaft 16 connected with a screwdriver bit 1, and a mounting groove 2 and a head cover 3 Composed of screwdriver head components. A sleeve 13 is installed on the end of the drive shaft 7 near the screwdriver head 1, and more than two large permanent magnets 15 are installed at equal intervals outside the sleeve 13, which is 4 in the present embodiment, and the output shaft 16 located in the sleeve 13 The small permanent magnets 5 with the same number of large permanent magnets 15 are installed at equal intervals. After the U-shaped shift fork 14 is inserted from the outside of the housing 12 and fixedly connected with the two ends of the sleeve 13, the U-shaped shift fork 14 drives the sleeve 13 to be able to Make an axial slide on the drive shaft 7, such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com