Production process of stainless steel door

A production process, stainless steel door technology, applied to door leaves, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of high moisture resistance and corrosion resistance, bathroom doors and room doors cannot be achieved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

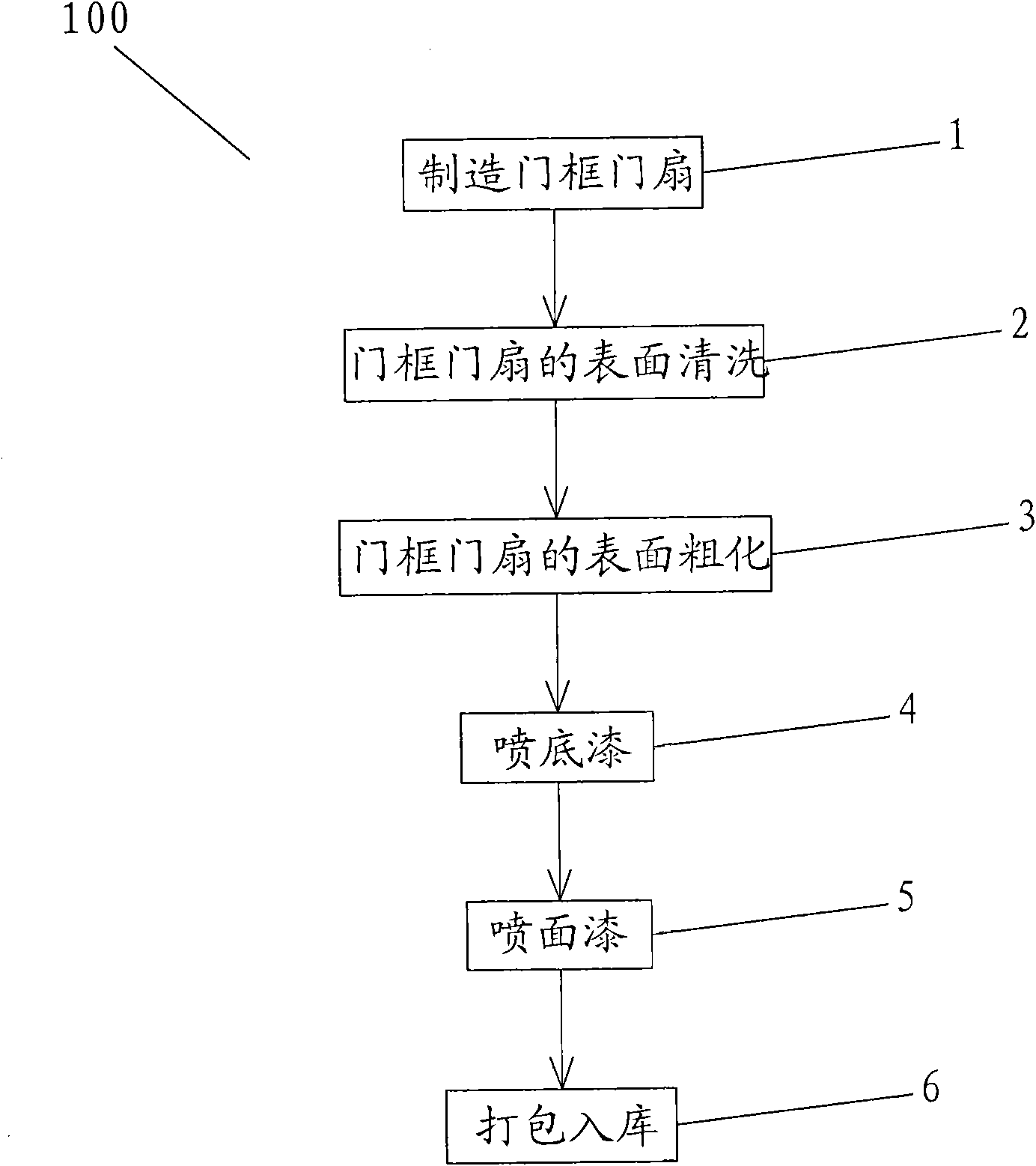

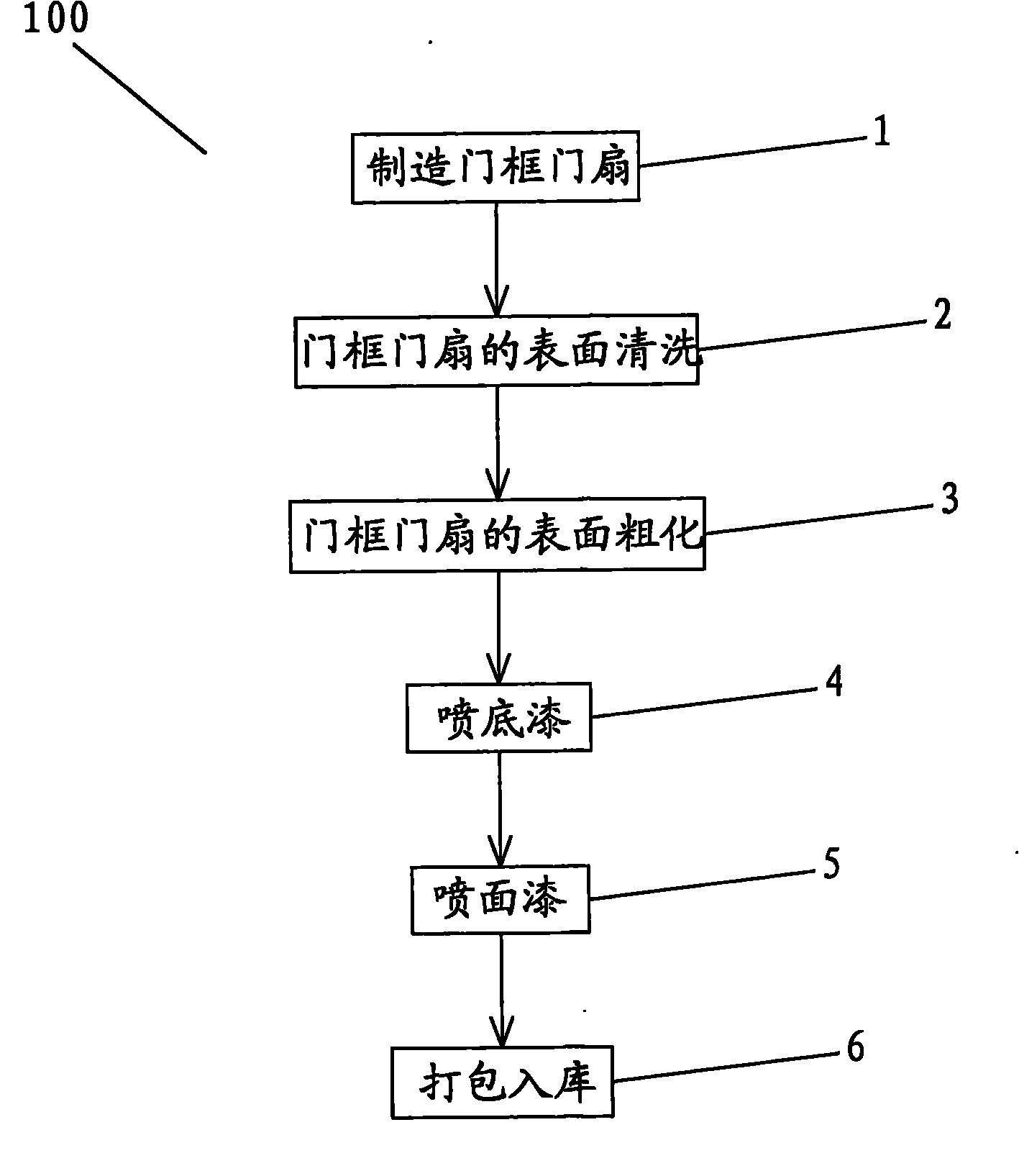

[0022] Such as figure 1 As shown, it is a schematic flow chart of a production process 100 of a stainless steel door involved in the present invention. It includes the following steps:

[0023] A. Manufacture door frame door leaf 1, which uses stainless steel plate, and the stainless steel plate is sequentially cut, bent, stamped and welded to form a door frame door leaf. The specific size and shape of the door frame door leaf are selected according to specific needs. ;

[0024] B. Clean the surface of the door frame and door leaf 2. First put the door frame and door leaf into the aqueous solution of degreasing agent and soak for 2 to 30 minutes, preferably 20 minutes. It has been proved by practice that if the soaking time is less than 2 minutes, it will cause degreasing and uncleanness If the time is too l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com