Blocking technological method of drillable oil layer

An oil layer and drilling technology, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve the problems of low oil production, low success rate, and poor economic benefits of oil wells, and achieve good economic benefits , high oil production, reliable plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

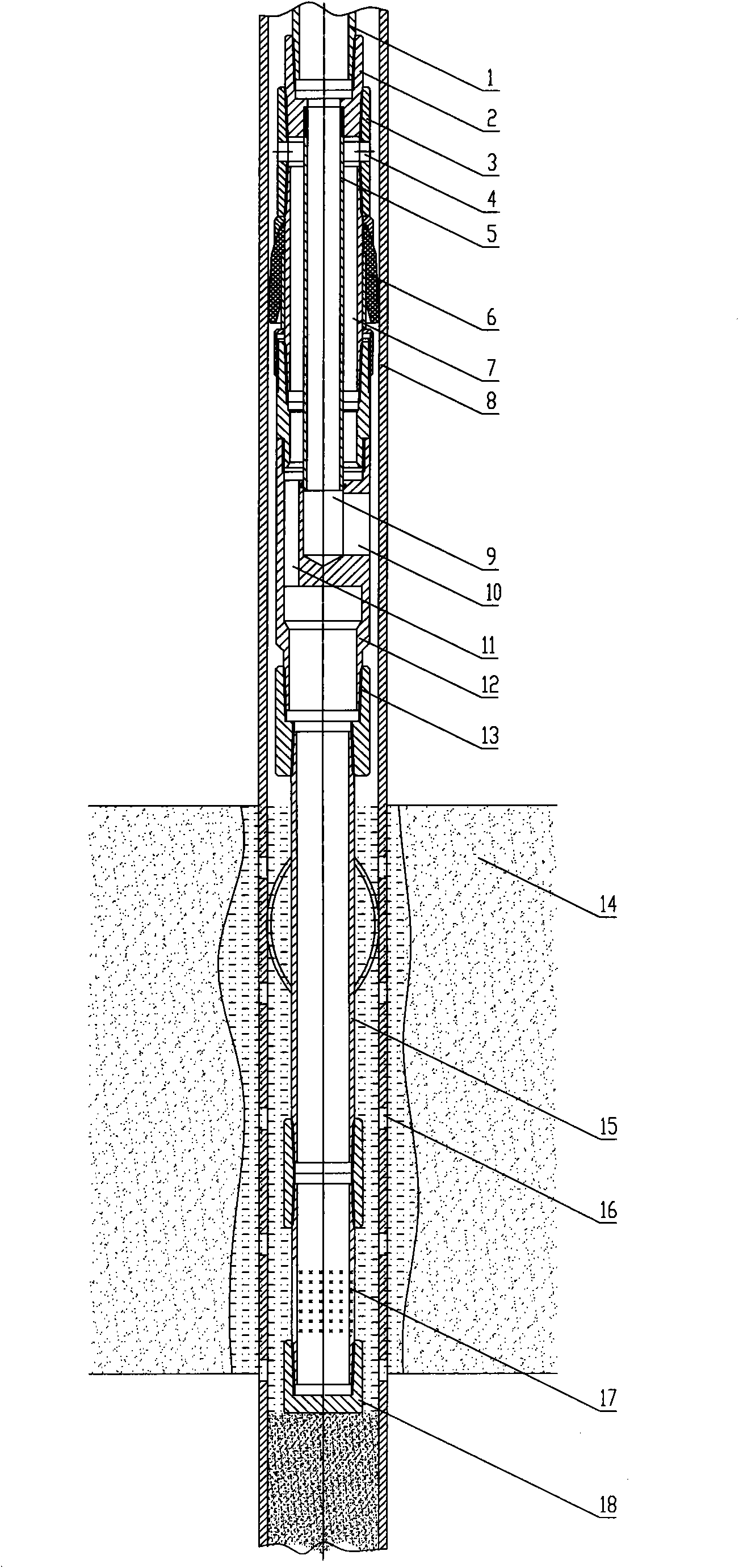

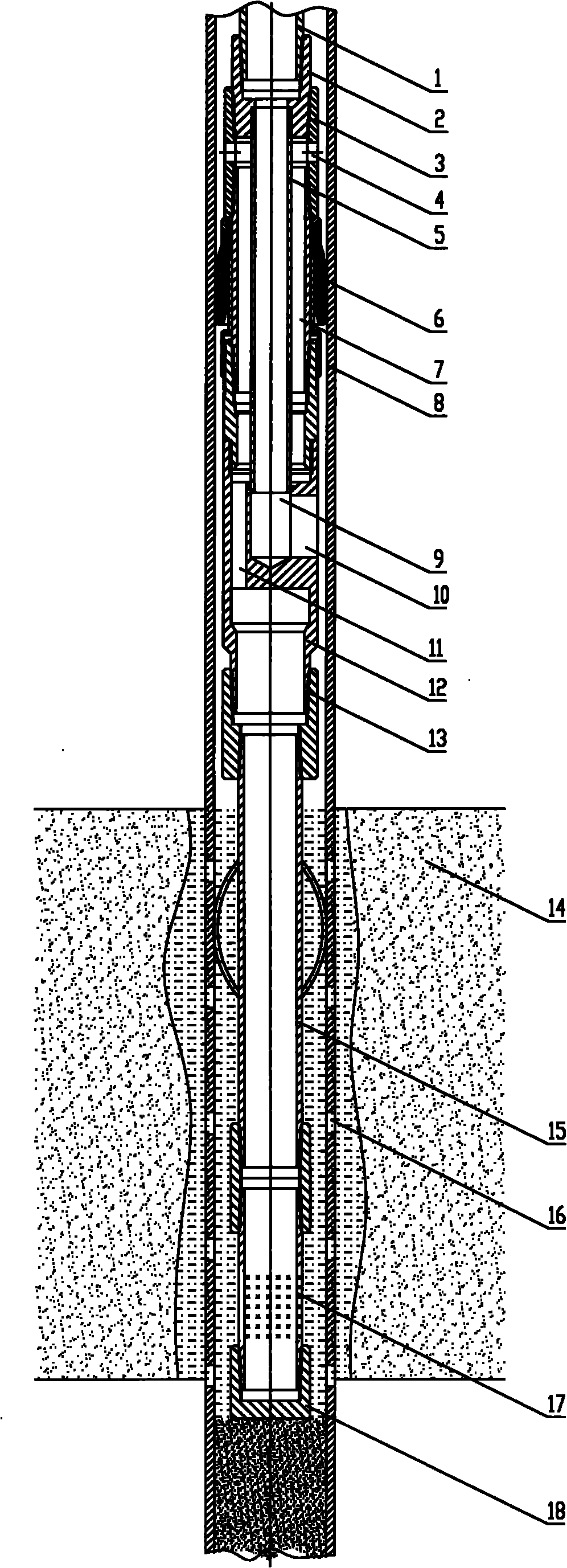

[0007] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0008] There are oil pipe 1, casing pipe 8, grouting tool assembly, reverse buckle joint 13, blocked oil layer 14, drillable pipe 15, signal pipe 17, blind plug 18, blast hole 16 on casing pipe 8, grouting tool assembly It consists of a three-button joint 2, a screen pipe 3, an inner pipe 5, a leather bowl seal 6, and a branch joint 12. The upper part of the three-button joint 2 is connected to the oil pipe 1, the lower part of the three-button joint 2 is connected to the upper part of the screen pipe 3, and the screen pipe 3. The lower part is connected to the upper part of the cup seal 6. The lower part of the cup seal 6 is connected to the upper part of the channel joint 12. There are screen holes 4 on the screen pipe 3. There are vertical holes 9, side channels 10, and vertical flow channels 11 on the channel joint 12. , the upper part of the inner pipe 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com