Heat exchange device

A technology of heat exchange devices and heat exchange tubes, which is applied in the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of complex structure and processing technology of heat exchange devices, which are difficult to popularize and apply on a large scale, Limitation of application range and other issues, to achieve the effect of improving heat exchange efficiency and heat exchange speed, reducing material and manufacturing costs, and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

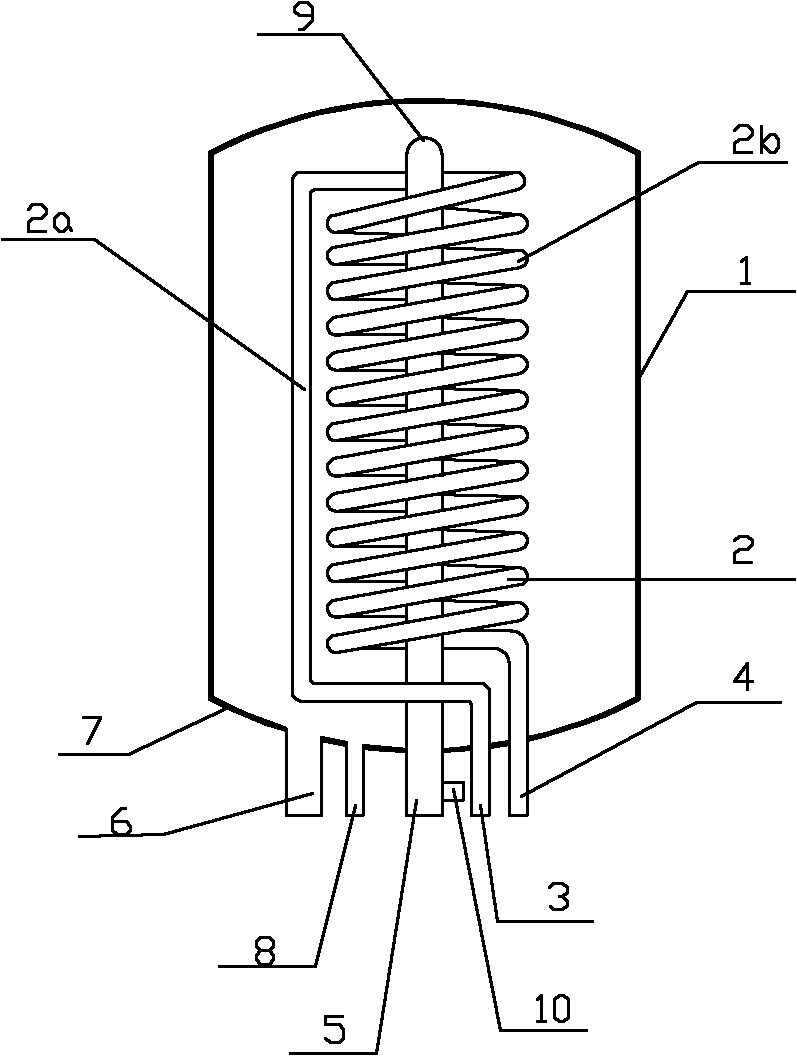

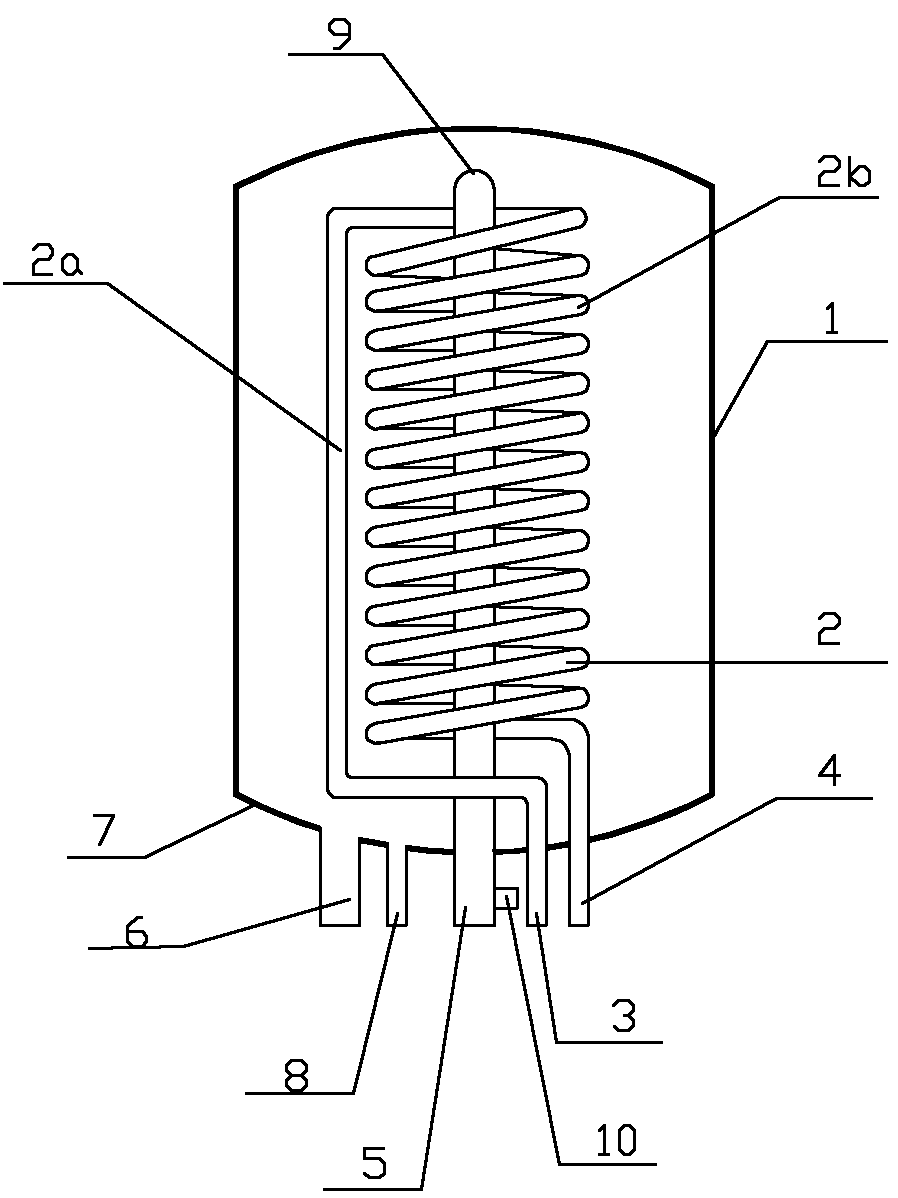

[0020] like figure 1 As shown, a heat exchange device includes a closed container 1, and a heat exchange module 2 is arranged in the container 1, and a high-temperature or low-temperature working fluid flows in the heat exchange module 2, which is used to exchange heat with the container 1 The liquid or gas performs heat exchange. The two ends of the heat exchange module 2 are respectively connected to the first tube 3 of the working medium and the second tube 4 of the working medium. The container 1 is fixedly connected with the first heat exchange tube 5 and the second heat exchange tube 6. The first heat exchange tube 5 and the second heat exchange tube 6 are used for inflow or outflow of heat exchange liquid or gas.

[0021] In this device, the first working medium tube 3, the second working medium tube 4, the first heat exchange tube 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com