Lead-free soldering-resistant full-silver conductive paste

A technology of silver conductor paste and lead-free glass powder, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems that are difficult to be used in thick film network resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of the above-mentioned all-silver electronic slurry includes the preparation process of an organic carrier and the slurry, and the preparation steps of the organic carrier are: A, drying the resin, drying the ethyl cellulose for more than 4 hours, and controlling its moisture content≤0.5 %; B, ingredients, weigh the solvent and polymer resin according to the formula; C, dissolve, put the container containing the solvent into the constant temperature water bath box, stir the solvent at a uniform speed with a dispersing mixer, and add the weighed resin at the same time, after adding the resin , continue to stir and dissolve until a uniform, transparent organic carrier is formed; D, add the organic solvent repeatedly, the amount of which is equivalent to the volatilized organic solvent, E, filter, and remove impurities from the carrier through a nylon filter; F, stand still, let The carrier is cooled and returned to normal temperature, and the cooling...

Embodiment 1

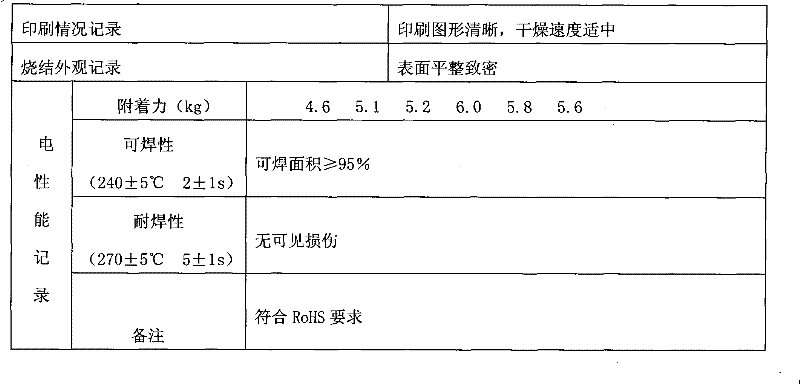

[0014] The lead-free solderable all-silver conductor paste is composed of 80wt% spherical silver powder, 5-12wt% organic solvent, 3-6wt% polymer resin and 1-7wt% lead-free glass powder. The specific surface of the spherical silver powder is 0.1-2.0m 2 / g. The lead-free glass powder is CuO-B 2 o 3 -SiO 2 -Bi 2 o 3 glass system. One or more, or all of the alcohol solvents, ester solvents, and ether solvents commonly used by those skilled in the art are used. The polymer resin is one or more of ethyl cellulose, hydrogenated rosin resin and polyurethane resin. By adopting the preparation method of the all-silver electronic paste of the basic scheme of the present invention, the performance of the all-silver electronic paste prepared is superior, as shown in Table 1. The slurry is applied to the chip network exclusion device, and the relevant electrical properties of the network exclusion device are good, as shown in Table 2.

Embodiment 2

[0016] The lead-free solderable all-silver conductor paste is composed of 81wt% spherical silver powder, 5-12wt% organic solvent, 3-6wt% polymer resin and 1-7wt% lead-free glass powder. The specific surface of the spherical silver powder is 0.1-2.0m 2 / g. The lead-free glass powder is CuO-B 2 o 3 -SiO 2 -Bi 2 o 3 glass system. The organic solvent is one or more, or all, of alcohol solvents, ester solvents, and ether solvents commonly used by those skilled in the art. The polymer resin is one or more of ethyl cellulose, hydrogenated rosin resin and polyurethane resin. By adopting the preparation method of the all-silver electronic paste of the basic scheme of the present invention, the performance of the all-silver electronic paste prepared is superior, as shown in Table 1. The slurry is applied to the chip network exclusion device, and the related electrical properties of the network exclusion device are good, as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com