Turn-back flow high-efficiency rectangular double-layer settling pond

A sedimentation tank and baffled flow technology, applied in the sedimentation tank and other directions, can solve the problems of structure optimization, flow state distribution cannot be properly solved, unstable sedimentation effect, affecting effluent quality, etc., so as to avoid floating mud on the water surface and enhance sedimentation Effectiveness and stability, overcoming the effect of a large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

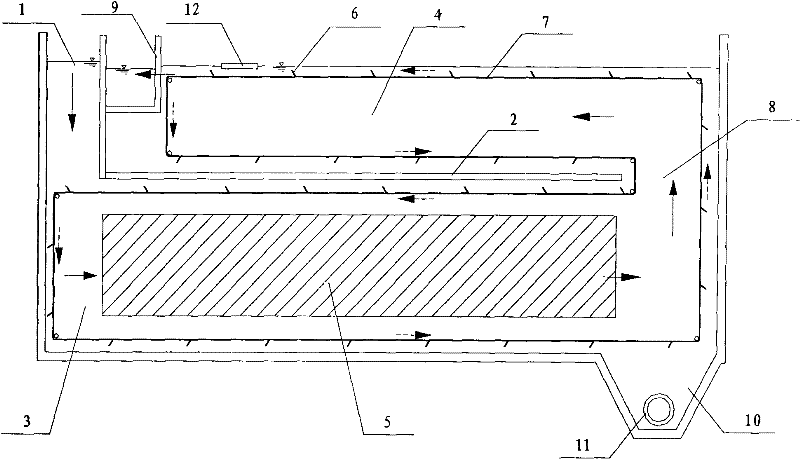

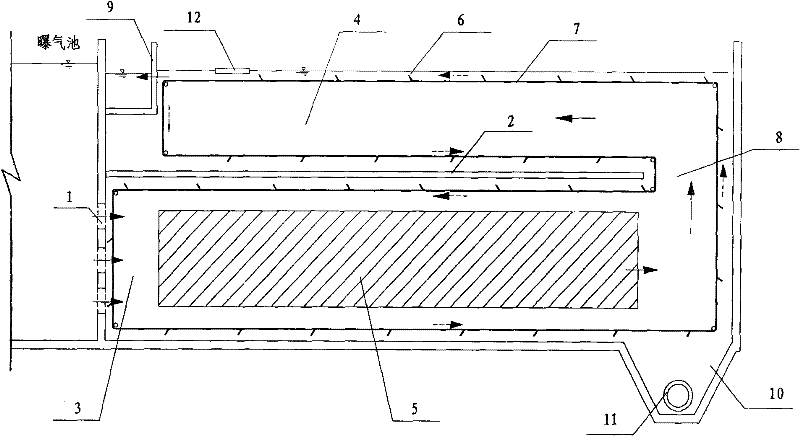

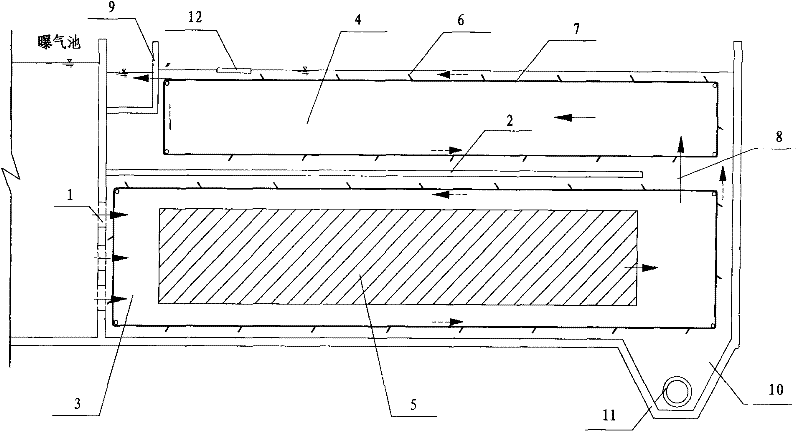

[0026] Such as figure 1 , figure 2 , image 3 As shown, the baffle type high-efficiency rectangular double-layer sedimentation tank system using the mud scraping device is implemented as follows: the sewage mixture enters the lower sedimentation zone (3) of the sedimentation tank through the water inlet channel or the perforated flower wall (1), and the lower sedimentation zone (3) is equipped with a lateral flow sloping plate (5), which improves the solid-liquid separation effect of the sewage mixed liquid, so that part of the solid phase substances in the sewage mixed liquid can be efficiently removed under the action of the sloping plate, and the sewage mixed liquid passes through The water hole (8) enters the upper advection sedimentation zone (4) for further sedimentation and separation, and finally the effluent is collected and flowed out through the effluent collection tank (9). After the flocs in the mixed solution settle and separate on the lateral flow inclined p...

Embodiment 2

[0028] Such as Figure 4 As shown, the baffle type high-efficiency rectangular double-layer sedimentation tank system using the scraper-suction device is implemented as follows: the sewage enters the lower sedimentation zone (3) of the sedimentation tank through the water inlet (1), and the lower sedimentation zone (3) A lateral flow inclined plate (5) is installed in the middle, which improves the solid-liquid separation effect of the sewage mixed liquid, so that part of the solid phase substances in the sewage mixed liquid can be efficiently removed under the action of the inclined plate, and the sewage mixed liquid passes through the water hole ( 8) Enter the upper advection sedimentation zone (4), further sedimentation and separation, and finally the effluent is collected and flowed out through the effluent collection tank (9). After the flocs in the sewage mixture are settled and separated by the lateral flow inclined plate (5) or settled along the way, they accumulate on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com