Low energy consumption desorption device and dehumidifying device thereof

A low energy consumption, desorption technology, applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problem of high energy consumption of adsorption and dehumidification devices, and achieve the effect of increasing the speed of desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to enable your review committee to have a further understanding and understanding of the characteristics, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be explained below, so that the review committee can understand the present invention The characteristics are described in detail as follows:

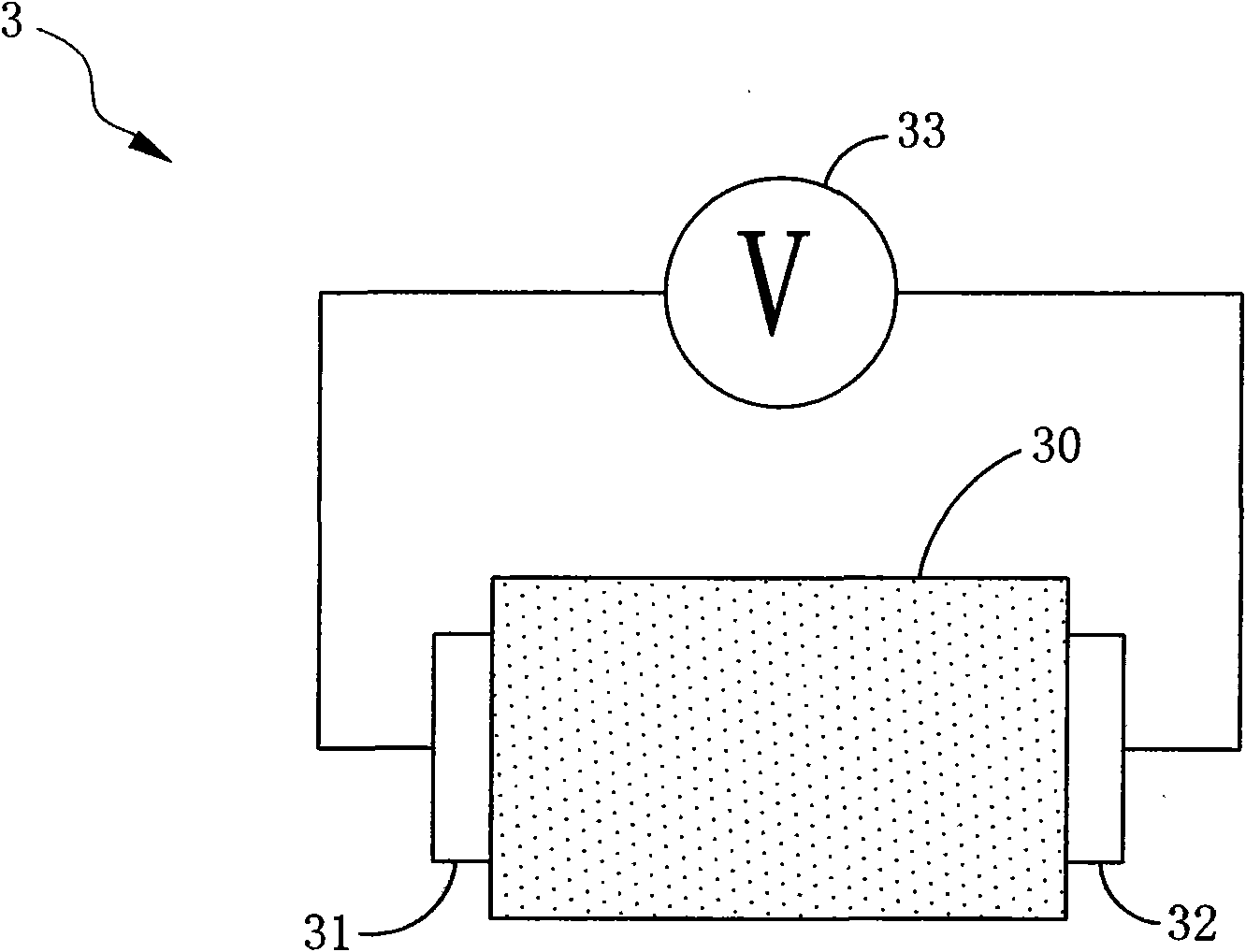

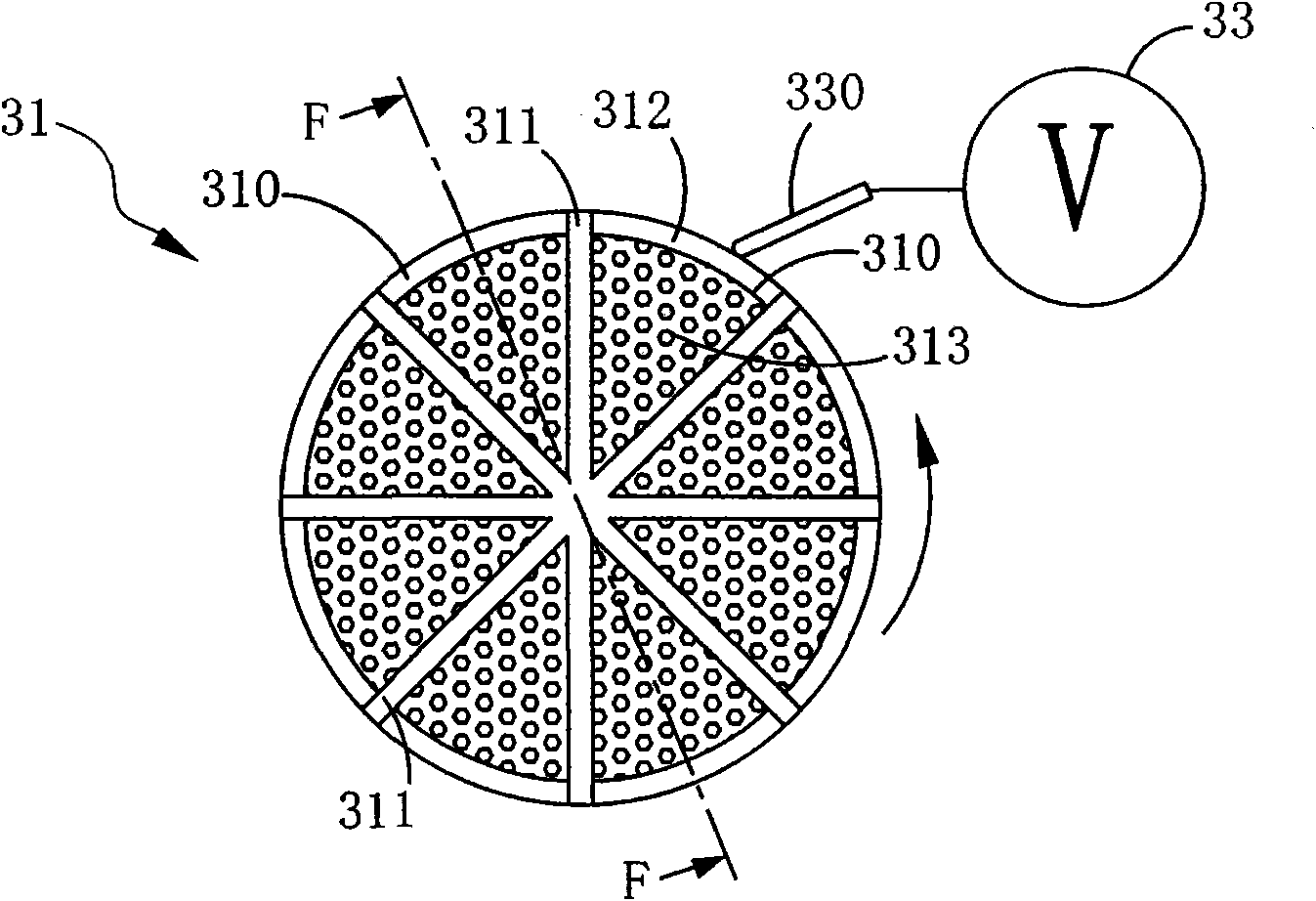

[0076] see figure 2 As shown, this figure is a schematic diagram of an embodiment of the low-energy desorption device of the present invention. In this embodiment, the desorption device 3 has an adsorption material 30 , a pair of electrode structures 31 and 32 and a voltage source 33 . The adsorption material 30 is used to adsorb organic volatiles, nitrogen or moisture contained in the air, but is not limited thereto. Generally speaking, it is more common that the adsorption material is applied to household dehumidification equipment, such as dehumidification wheel dehumid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com