Warp knitting machine

A technology of warp knitting machine and bar, which is applied in the field of warp knitting machine and can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

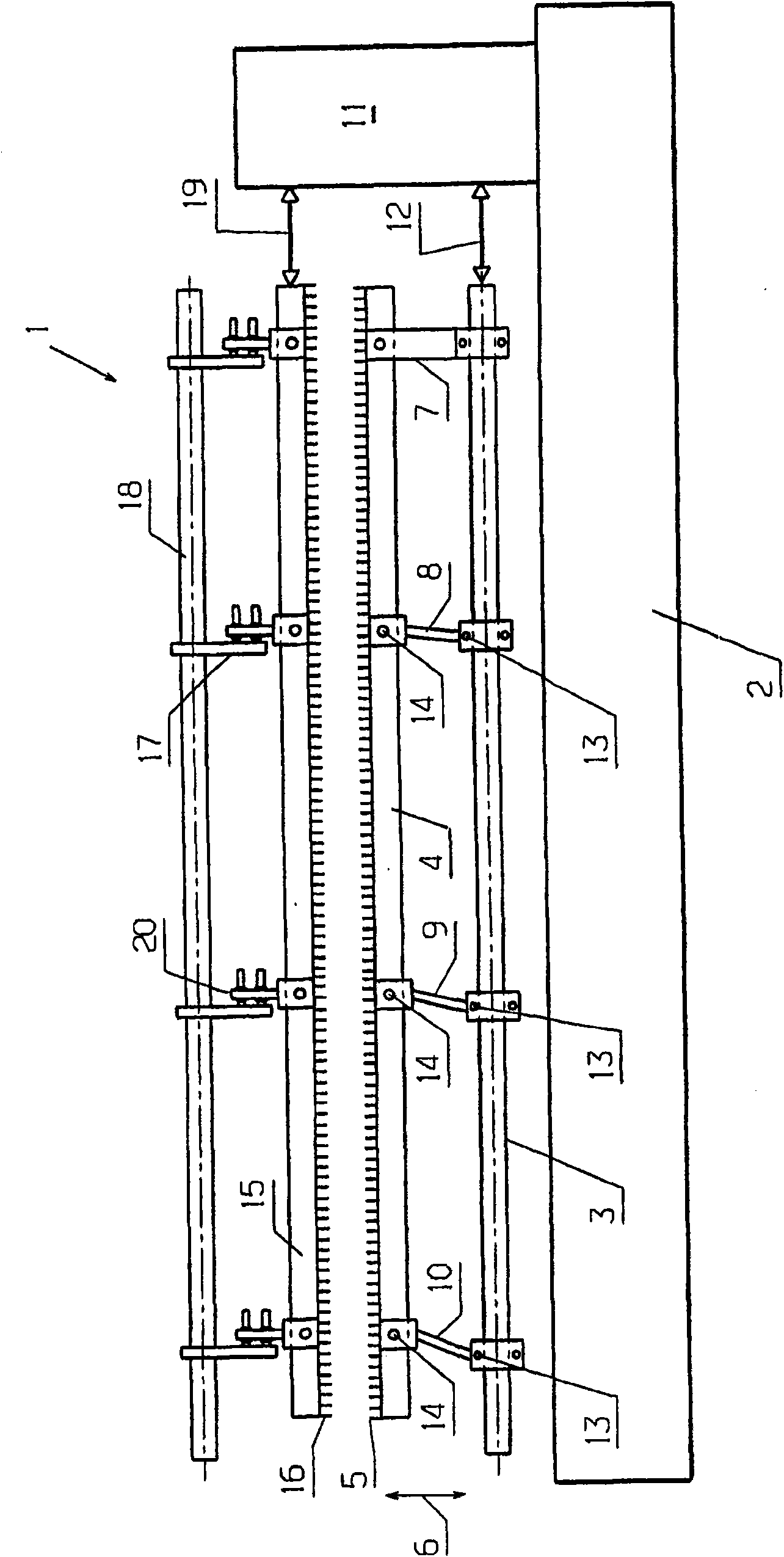

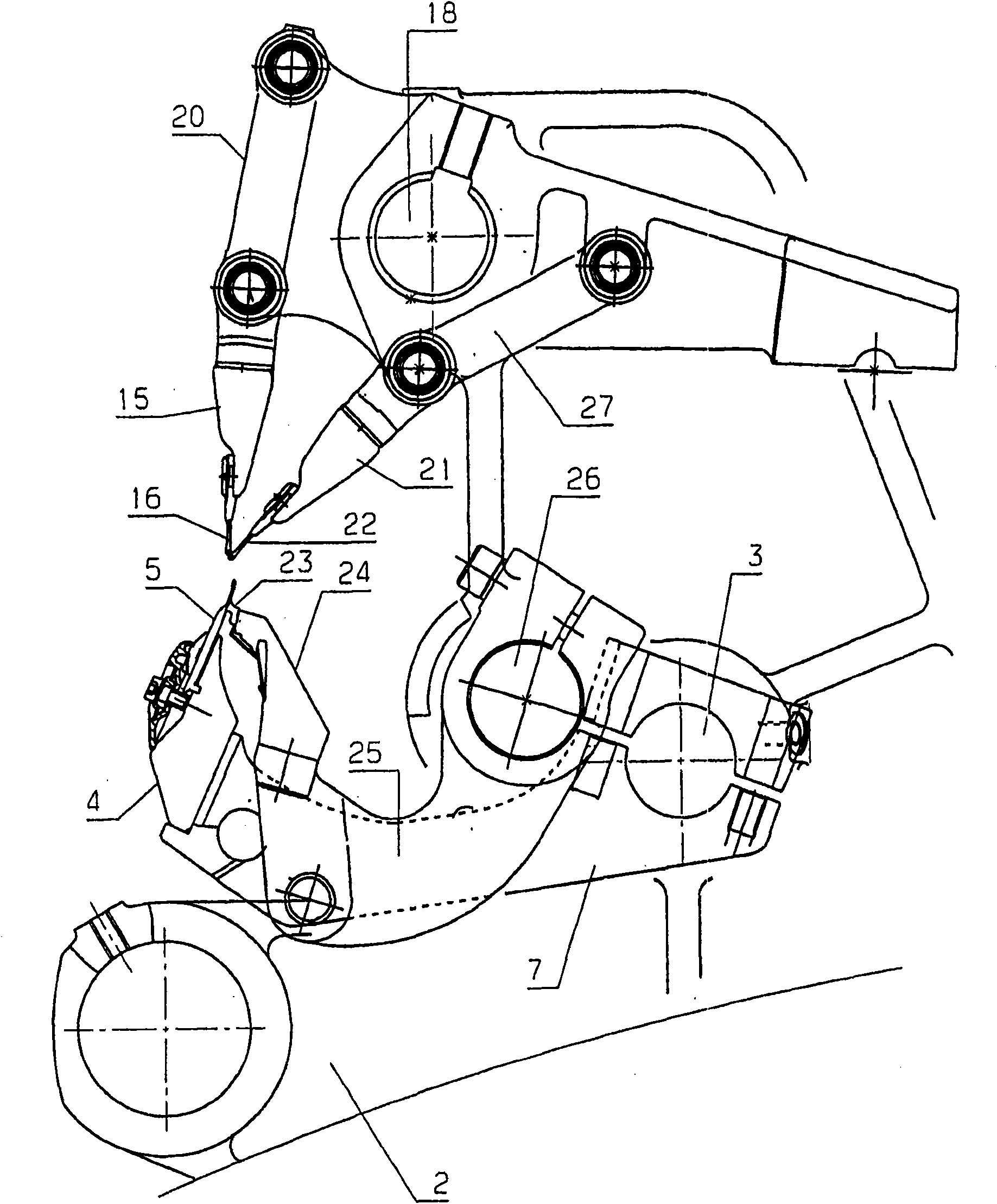

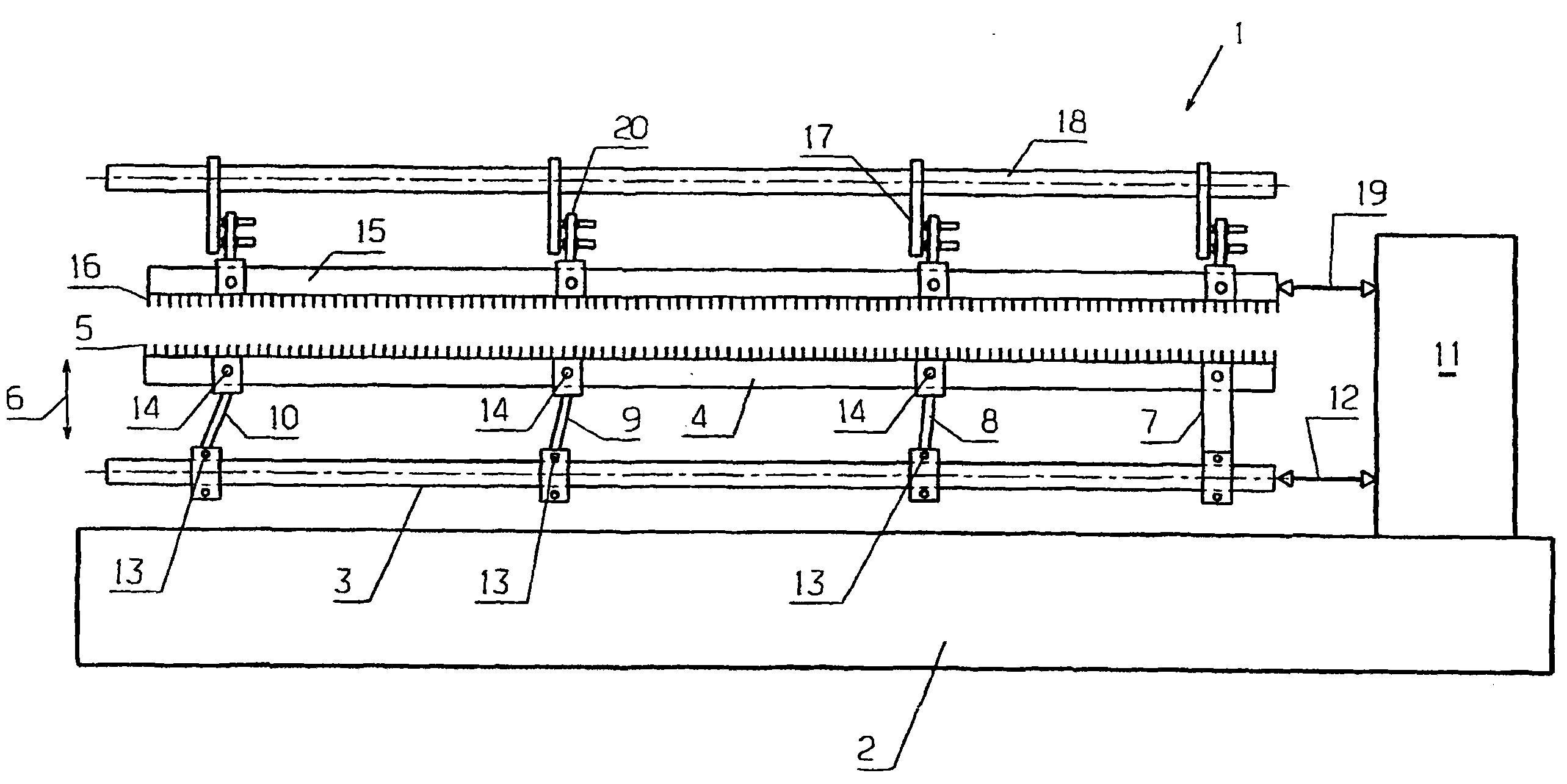

[0023] The warp knitting machine 1 has a frame 2 in which a support shaft 3 is mounted in a manner not shown in detail. The support shaft 3 is made of steel or another metal, for example.

[0024] A knitting tool bar 4 is suspended on the support shaft 3, and a large number of knitting needles 5 are equipped with the knitting tool bar 4. For the production of fabrics not shown in detail, the knitting needle 5 must make a reciprocating movement in the direction of the double arrow 6 during each looping process, that is, in the direction of the double arrow 6. figure 1 Make up and down movements.

[0025] The bearing shaft 3 is designed as a continuous bearing shaft. The support shaft 3 is connected with the knitting tool bar by a plurality of support rods 7-10. In this regard, the support bar 7 arranged on the end of the looping tool bar 4 adjacent to the jacquard drive 11 is designed as a fixed bar, that is, the fixed bar 7 does not allow the support shaft 3 and the looping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com