Drill loader

A technology for drilling and loading machines, which is applied in cutting machinery, earth-moving drilling and mining, etc., can solve the problems of repeated transportation and transportation of rock drilling and transportation equipment, and achieve the effects of convenient operation and maintenance, diversified functions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

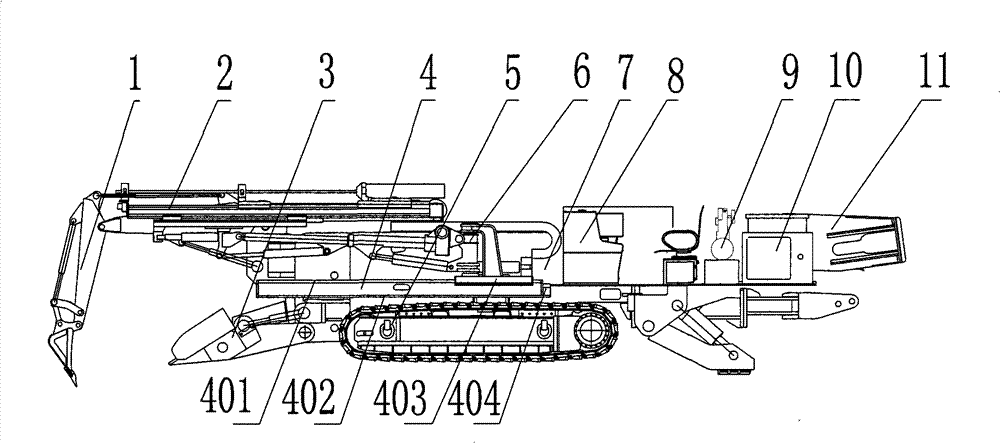

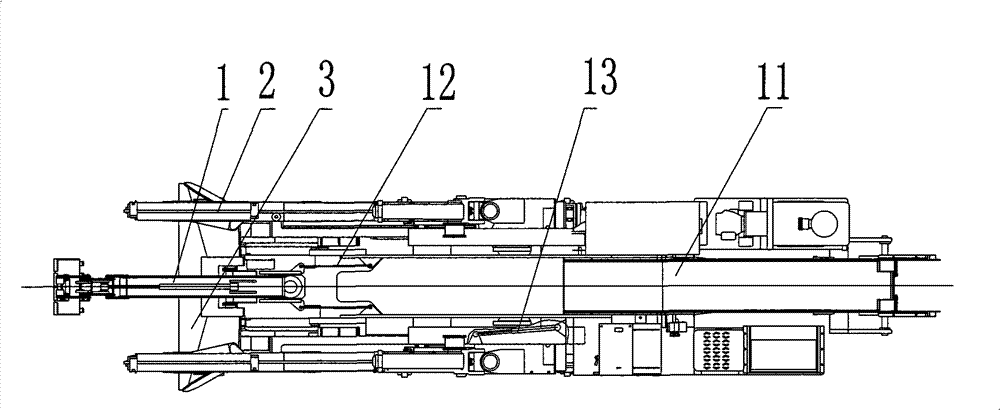

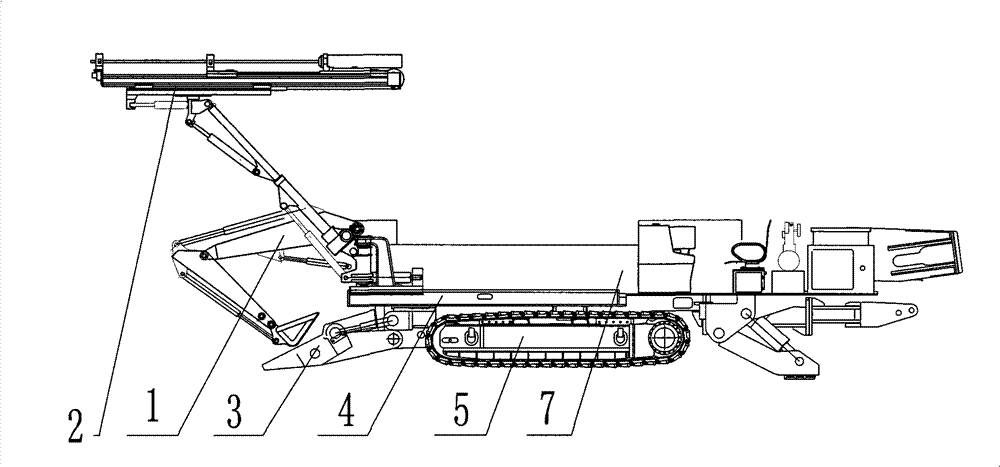

[0030] like Figure 1 ~ Figure 3 As shown, the present invention is a fully hydraulic drilling rig, which includes: rigging machine 1, rock drilling mechanism 2, shoveling part 3, crawler walking part 5, frame 7, hydraulic system 8, air supply system 9, electrical system 10 , transport plane 11 etc. The specific structure is as follows:

[0031] The crawler walking part 5 is installed on both sides of the frame 7, driven by a motor driven travel reducer, the conveyor 11 is installed in the middle of the frame 7, the shovel part 3 is hinged at the lower part of the front end of the frame 7, the hydraulic system 8, the air supply system 9 1. The electrical system 10 is installed on the frame 7, the lifting machine 1 is hinged on the upper front end of the frame 7, the frame 7 is fixed with a slide table 4, the slide table 4 is hinged with a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com