Valve

A valve and valve body technology, applied in the field of mechanical valves, can solve the problems of gas leakage, easy failure of rubber membrane seals, etc., and achieve the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

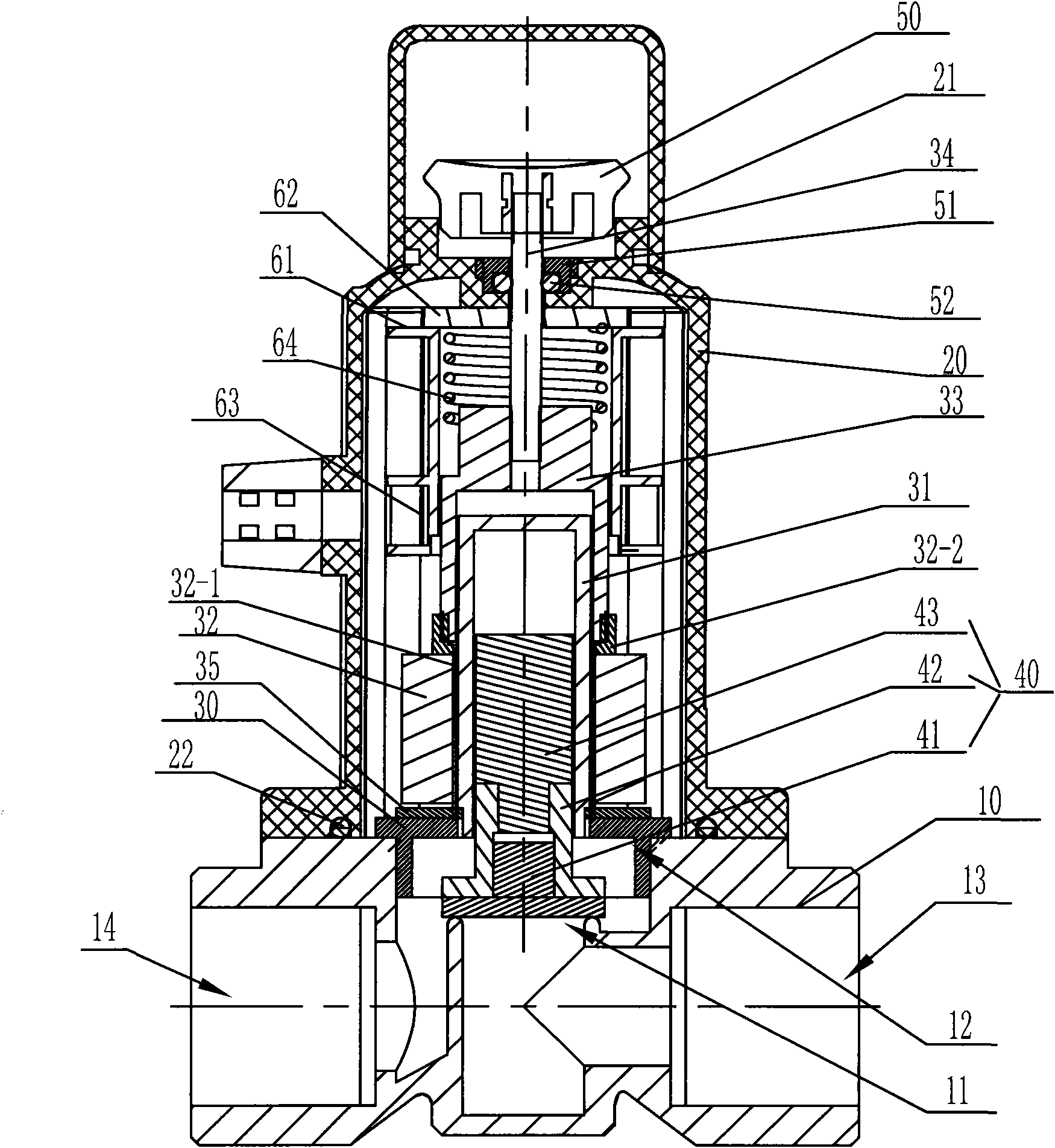

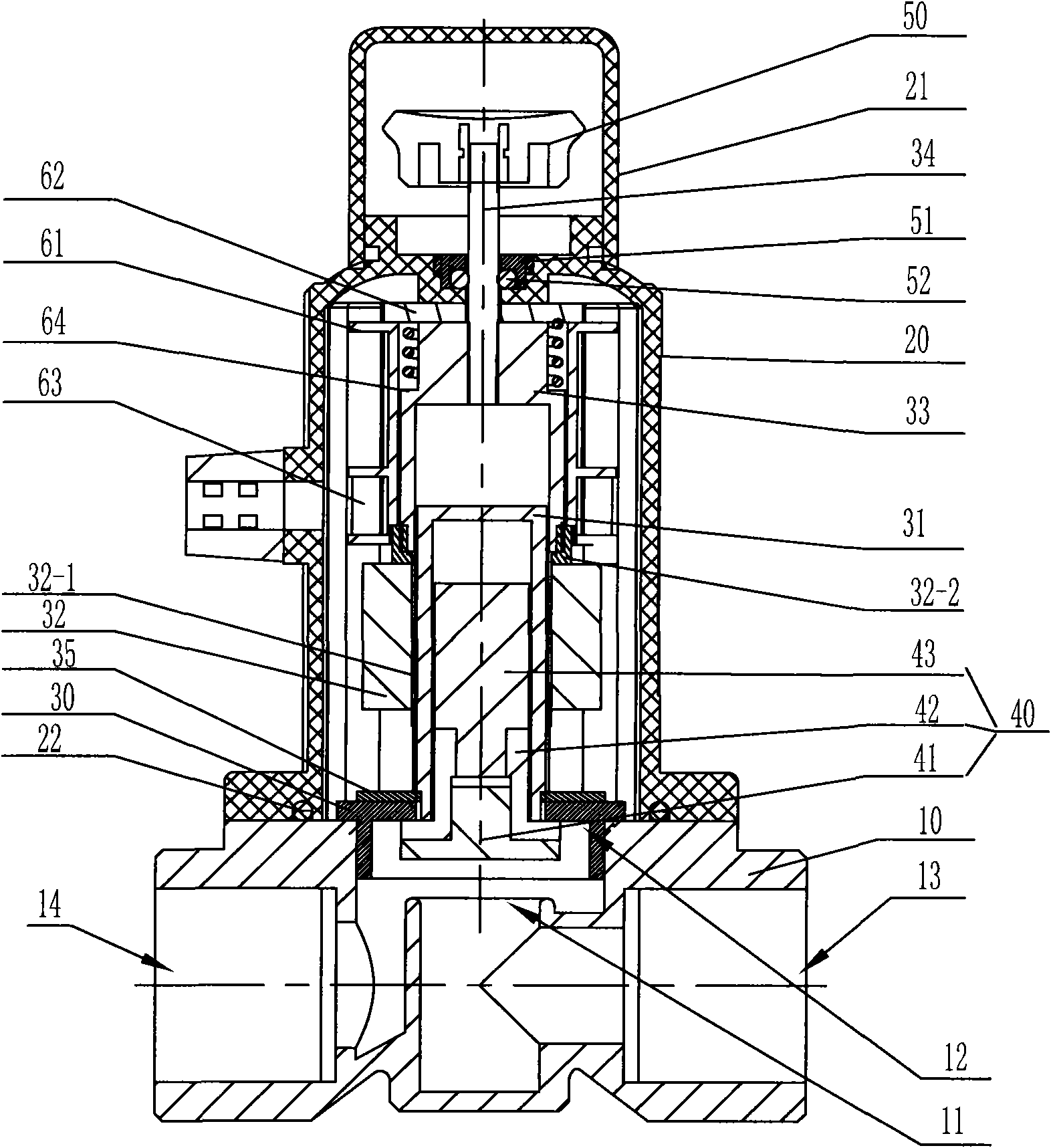

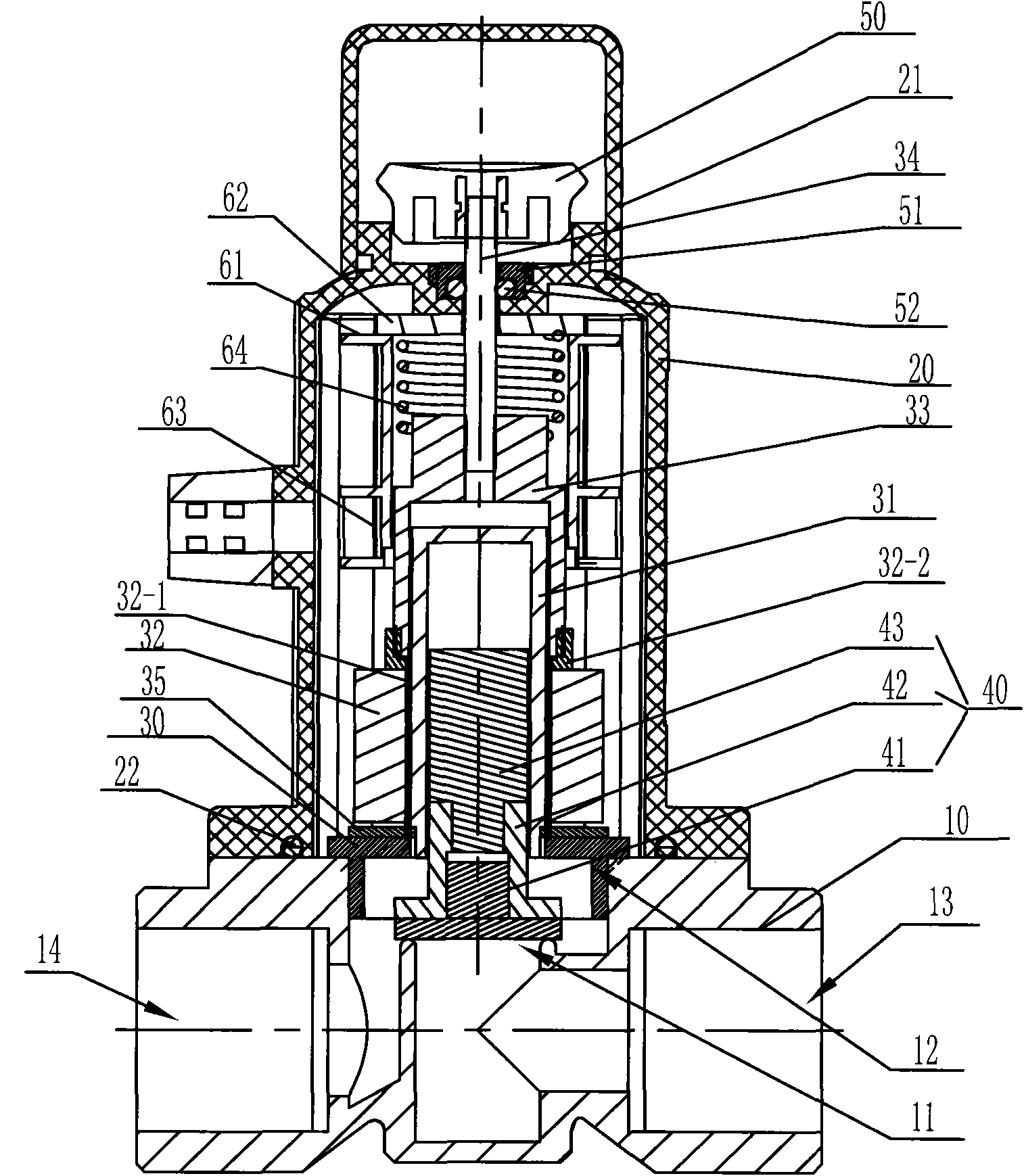

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] A valve, including a valve body and a valve casing, the valve body has a switch port and a large socket, the large socket of the valve body adopts a fixed non-rubber seal, and the fixed non-rubber seal refers to the large socket with the valve body The threaded nut and the upper part of the nut are sealed and connected to the sleeve, and the nut and the sleeve are made of metal material or non-metallic hard material that does not attract magnetism.

[0041] The nut made of non-magnetic material is threadedly connected to the large sleeve of the valve body (the large sleeve is provided with an internal thread) and the sleeve on the upper part of the nut is used to achieve sealing. The rubber membrane seal usually used is abandoned, and the valve is opened and closed. When closed, the nut is always fixedly connected with the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com