Automatic detection electronic check tool for automobile glass

A technology for auto glass and automatic detection, applied in the direction of measuring devices, using electrical devices, using electromagnetic means, etc., can solve the problems of poor preparation of measurement results, high manual labor intensity, and low measurement efficiency, so as to reduce labor intensity and improve The effect of measurement efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

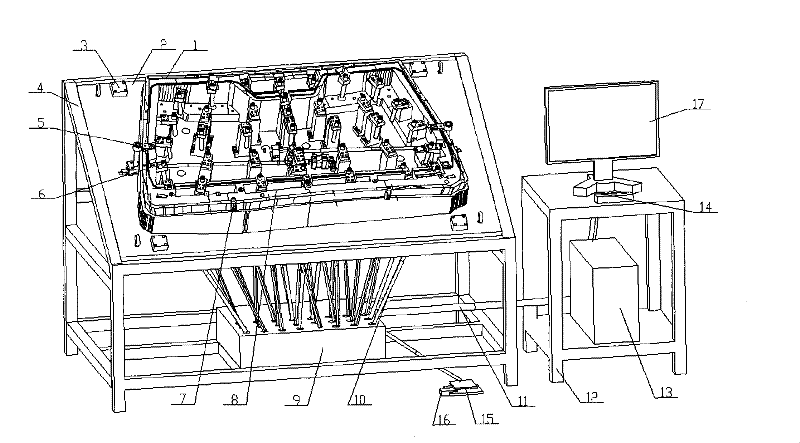

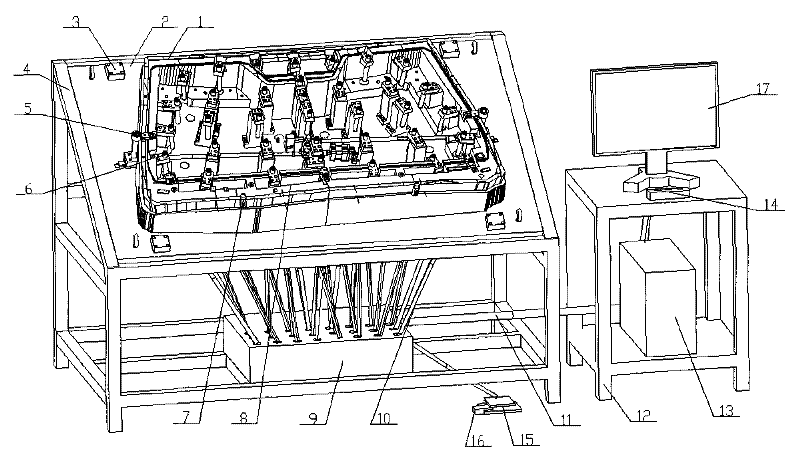

[0017] Such as figure 1 As shown, an electronic inspection tool for automatic detection of automobile glass, the inspection tool includes inspection body 1, inspection tool angle frame 4, inspection tool centering mechanism 5, electronic probe 6, inspection tool positioning block 7, automotive glass 8, electronic detector Needle electrical box 9, electronic probe connection line 10, data connection line 11, industrial computer host 13, the inspection body 1 is set on the inspection tool angle frame 4, and the inspection tool angle frame 4 is provided with a cast aluminum plate with reinforcing ribs 2. Use the cast aluminum plate 2 with reinforcing ribs to strengthen the strength of the bottom plate of the inspection tool. The inspection body 1 is placed on the angle frame 4 of the inspection tool to make it consistent with the loading angle and direction, so as to achieve the same effect as the loading effect. Casting with reinforcing ribs The periphery of the aluminum plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com