Reflection-type optical fiber temperature sensor

An optical fiber temperature and sensor technology, used in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of multiple end face losses reducing total coupling efficiency, unfavorable portable products, etc., to improve light source utilization, temperature measurement. Wide range, the effect of reducing divergence loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

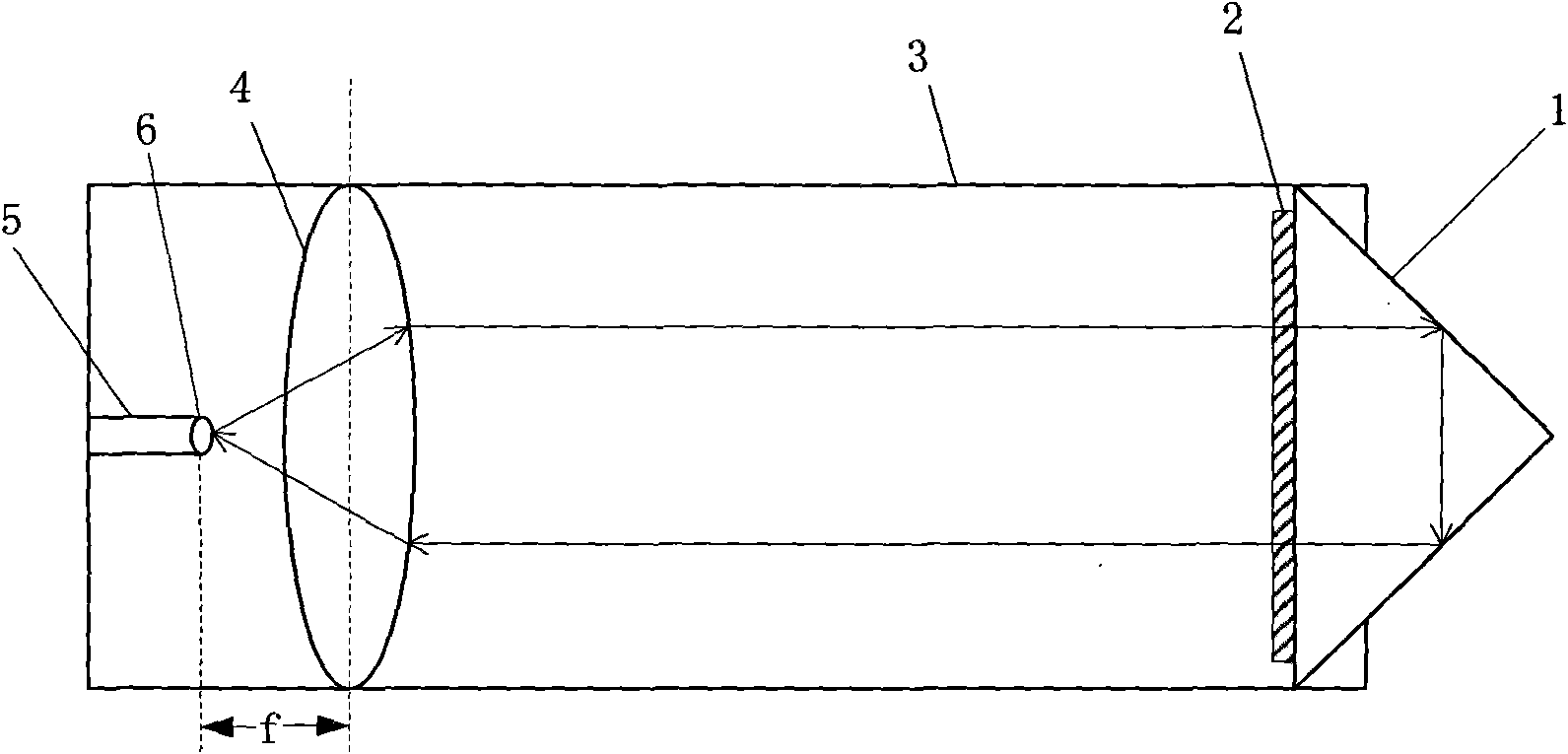

[0032] Such as figure 1 As shown, a reflective optical fiber temperature sensor includes a sapphire sleeve 3, a sapphire isosceles right-angled prism 1 positioned at one end of the sapphire sleeve 3 and a sapphire convex lens 4 positioned at the other end of the sapphire sleeve 3, and the sapphire isosceles right-angled prism 1 The crystal axis orientation of the hypotenuse surface is (0001), and the hypotenuse surface of the sapphire isosceles right-angled prism 1 faces the inner side of the casing 3, and the hypotenuse surface of the sapphire isosceles right-angle prism 1 is coated with ZnO film 2, ZnO film 2 The crystal axis orientation is (0002), and the thickness is about 500nm;

[0033] The other side of the sapphire convex lens 4 relative to the sapphire isosceles rectangular prism 1 is provided with an optical fiber 5 for transmitting light, and the end face 6 of the optical fiber 5 is located at the focal point of the sapphire convex lens 4;

[0034] The optical axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com