Gas cylinder tester with digital image analysis external measuring method

A digital image and test device technology, which is applied in the direction of measuring devices, optical devices, and machine/structural component testing, can solve the problems of difficult measurement of water volume changes in the water jacket, interference from external conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

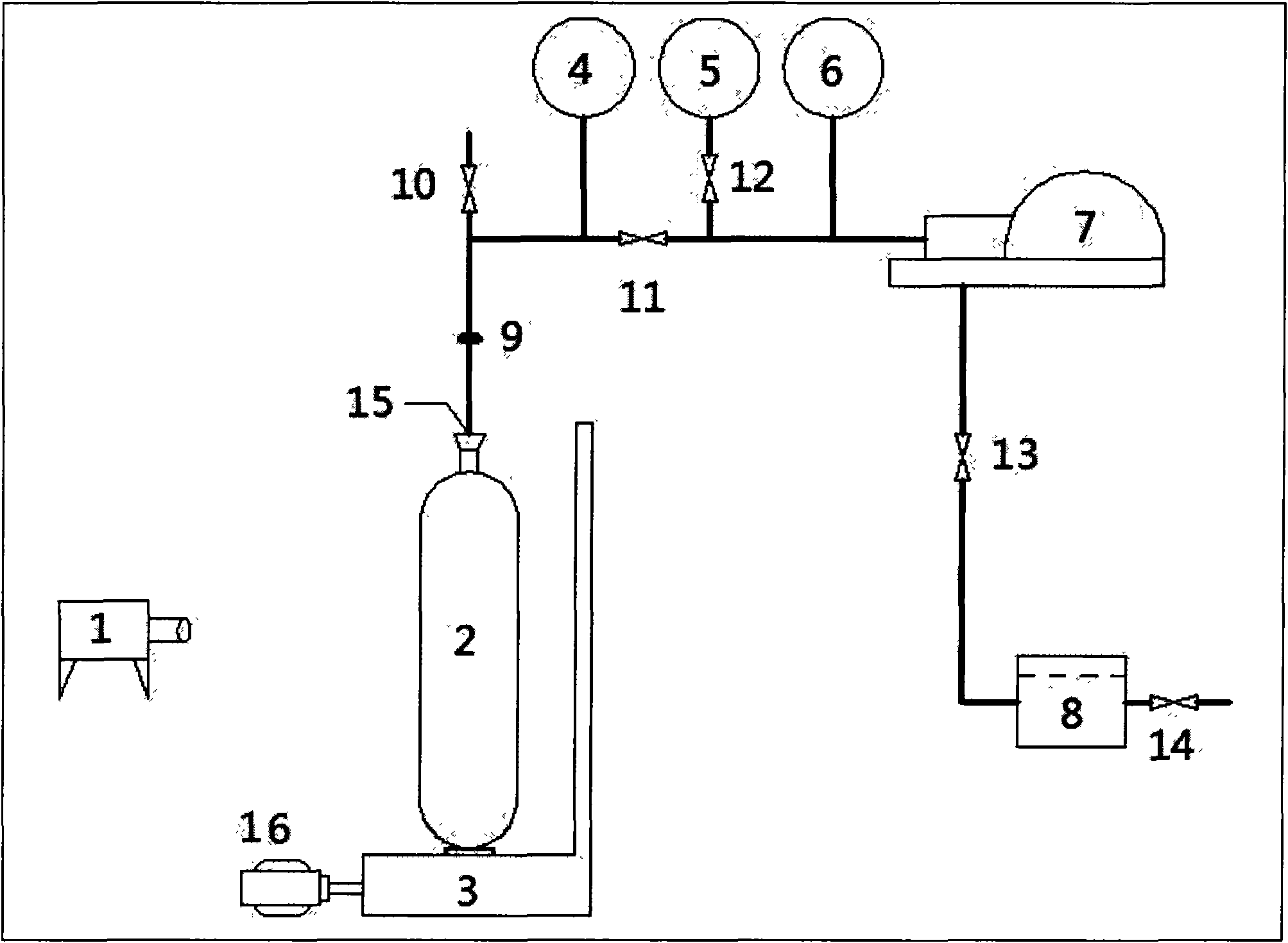

[0033] specific implementation plan

[0034] 1) Record the relevant data of the test bottle

[0035] 2) Install the test bottle

[0036] 3) Exhaust

[0037] Open valves 10 and 11, start hydraulic pump 7, stop hydraulic pump 7 after exhausting the air in the pressure pipeline, and close valve 10.

[0038] 4) Stand still

[0039] Using an image analysis program, the current volume of the bottle 2 under test is acquired through the digital camera 1 . After standing still for 30s, monitor whether the volume of the bottle 2 under test drifts, and if there is no drift in the volume, it can be transferred to the next step. Otherwise, repeat this step.

[0040] 5) Zero adjustment

[0041] The volume of the tested bottle 2 obtained by the digital camera 1 is taken as the original volume of the tested bottle 2, that is, the volume change of the tested bottle 2 is zero at this time, and the volume changes of the following tests are all based on this zero position.

[0042] 6) Leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com