Girdle photon sieve and manufacturing method thereof

A technology of photon sieve and annular zone, applied in optics, optical components, microlithography exposure equipment, etc., can solve the problem that the far-field main lobe is not small enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

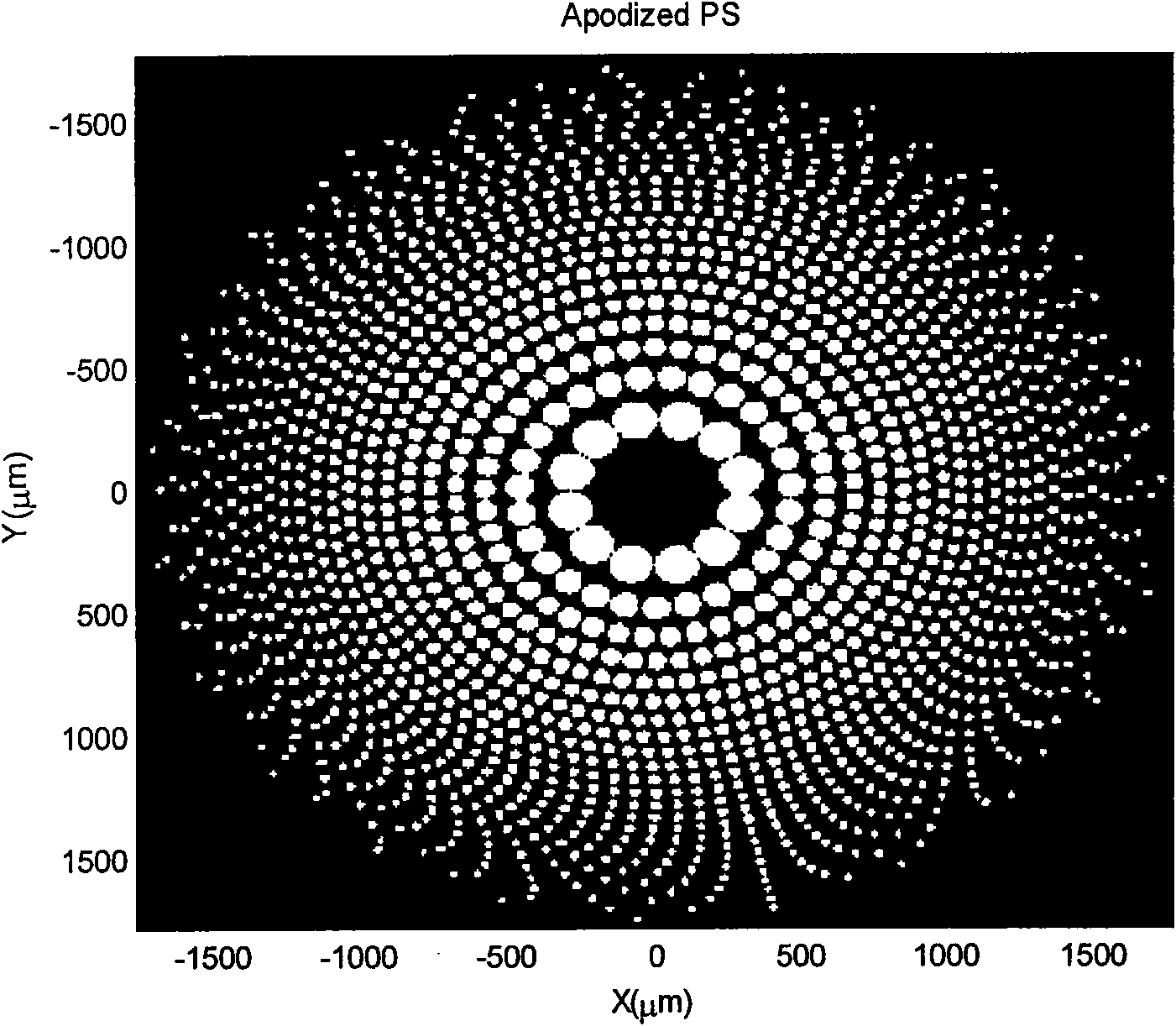

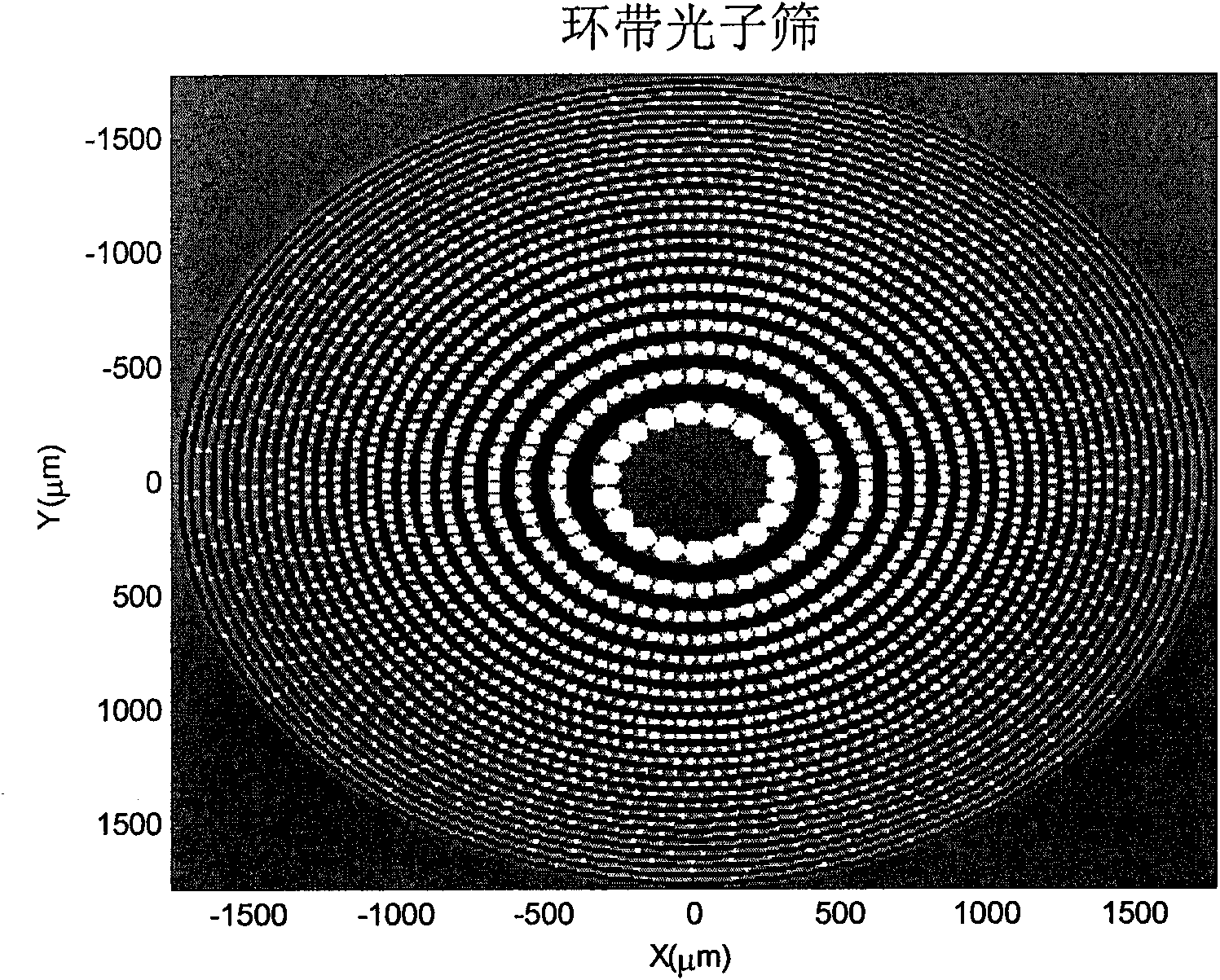

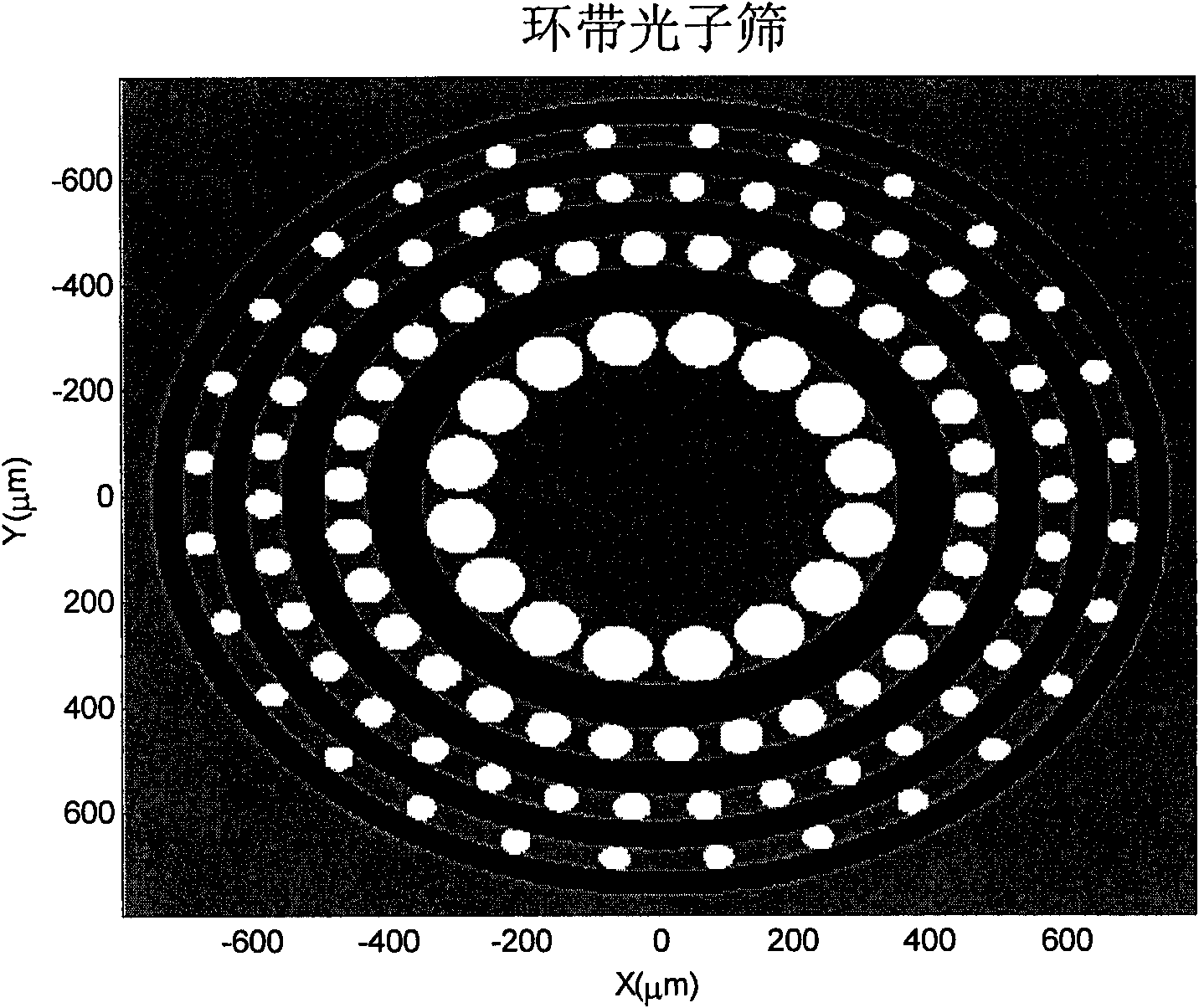

[0038]Ring photon sieve is a new type of diffractive optical phase element, that is, phase plate. The phase plate is placed before or after the diffraction-limited lens, and corrects the light intensity of each spectrum of the far-field diffraction spot of the laser beam to achieve a diffraction center diffraction spot with more concentrated energy than the diffraction center spot of an ordinary photon sieve. The phase plate (annular photon sieve) of the present invention adopts a smaller diffraction circular hole and an etched diffraction ring structure with a phase of π to replace the single-circle diffraction aperture of an ordinary photon sieve. The position and number of diffraction units are consistent with ordinary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com