Kong-clan heat dissipation method

A heat conduction plate and high thermal conductivity technology, applied in the field of Kong’s heat dissipation method, can solve the problems of high cost, low heat dissipation efficiency, power consumption and noise of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

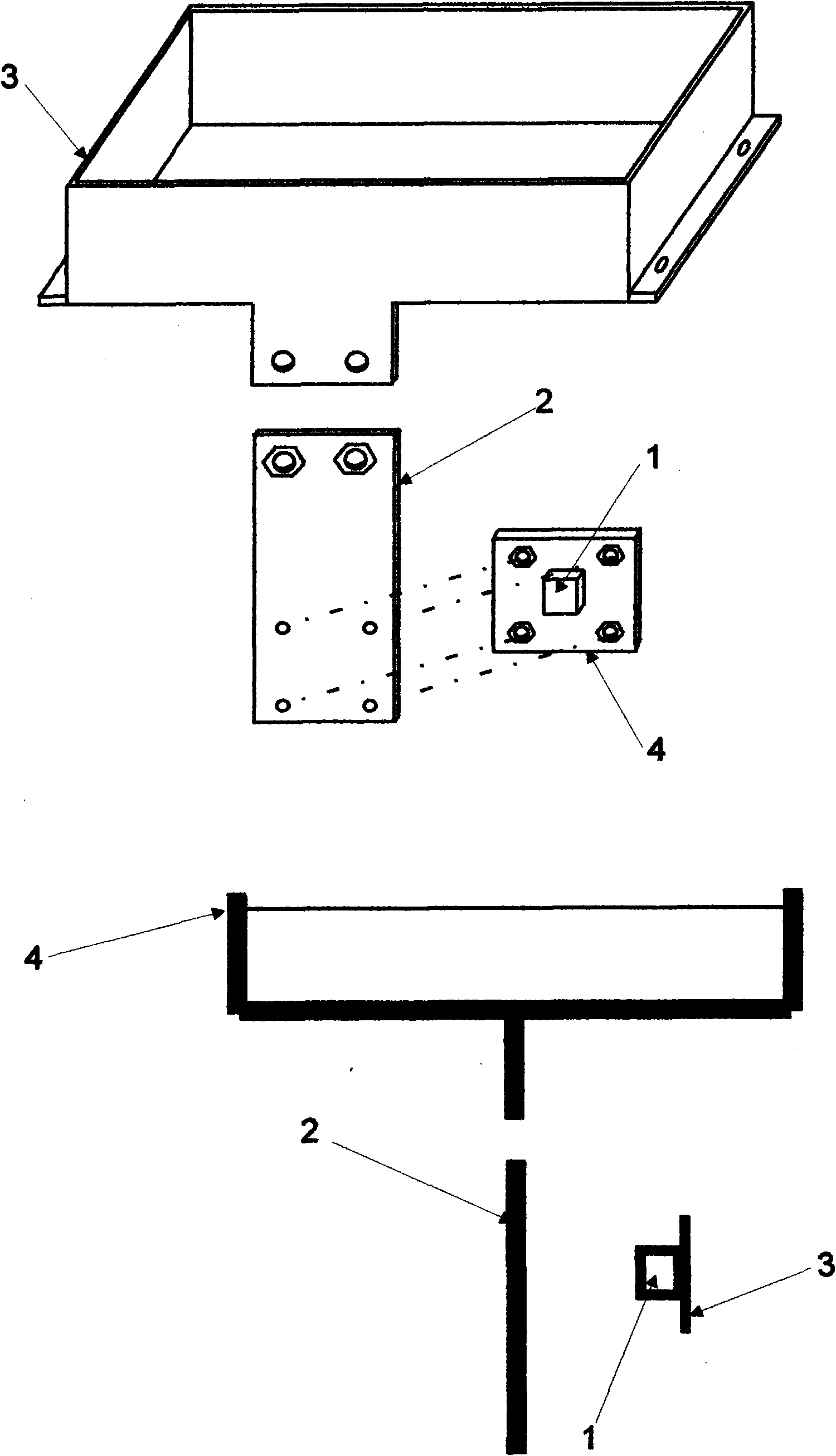

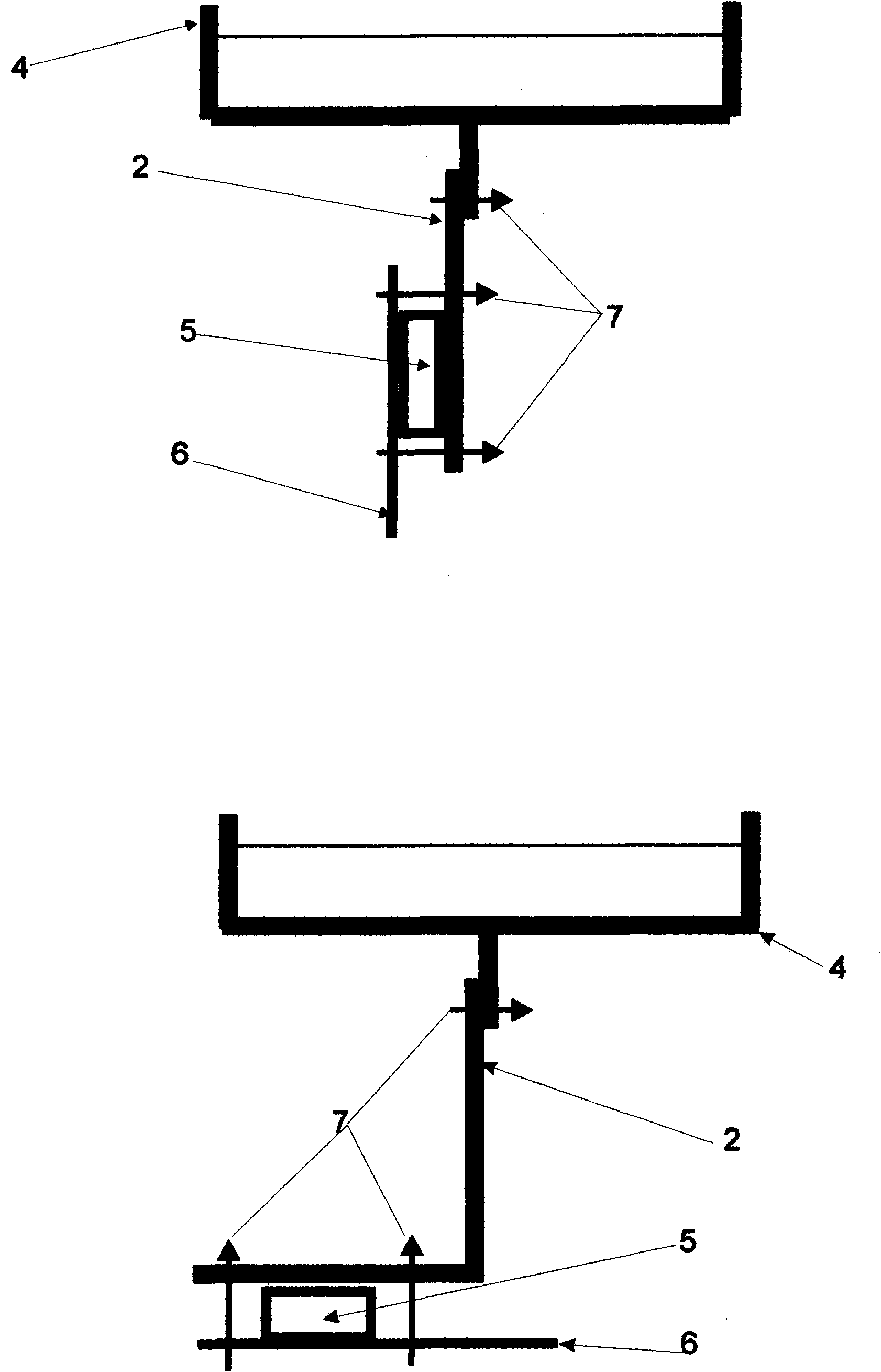

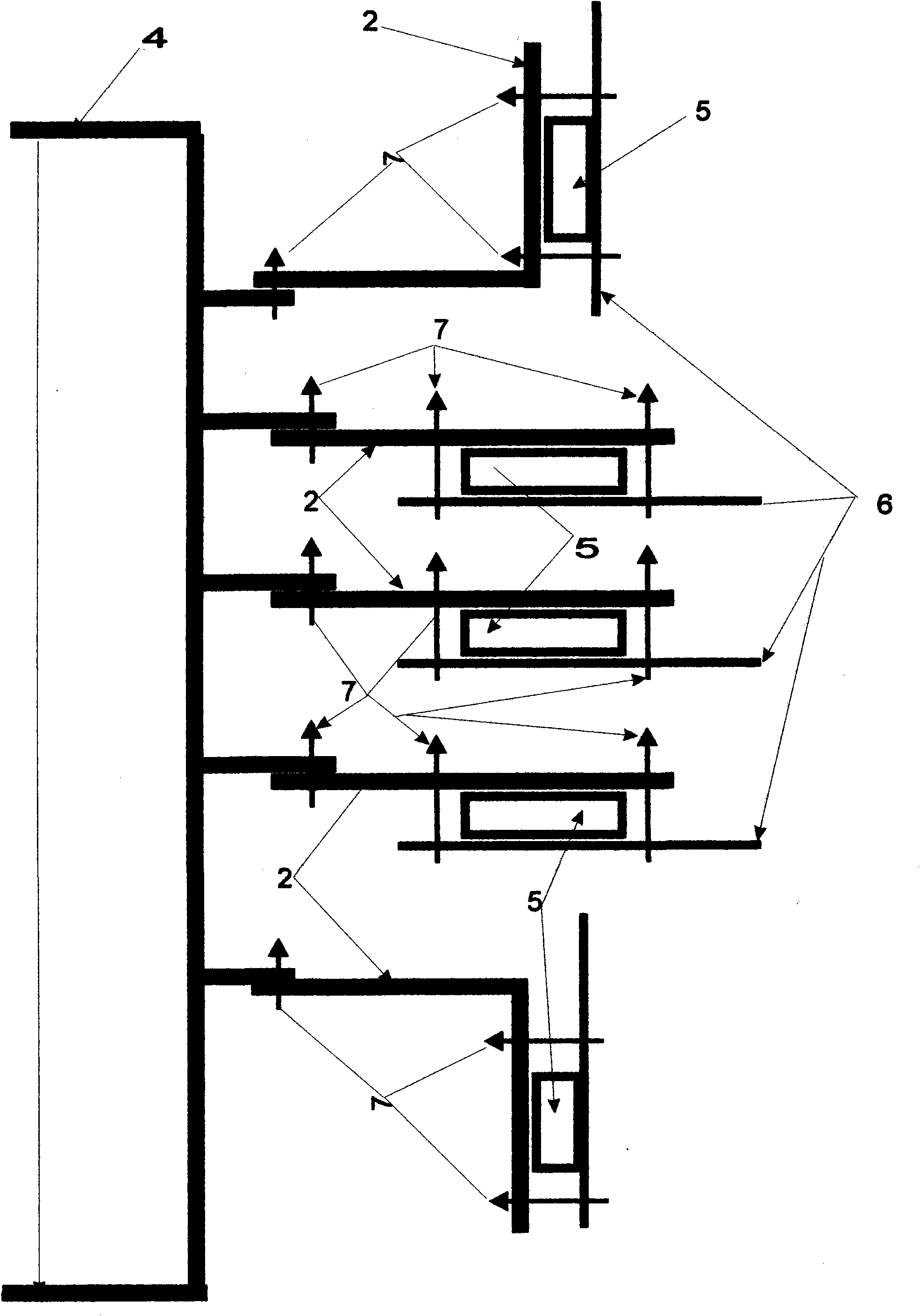

[0023] Please refer to figure 1 Schematic diagram of the composition of the basic radiator of the present invention, an example of which is a low-power radiator.

[0024] in this figure 1 Among them, the upper picture is the physical picture, and the lower picture is the cross-sectional view. The radiator is basically composed of a heat conducting plate 2 and an open water tank 4, both of which are made of metal materials with high thermal conductivity, and are insulated after surface treatment such as surface oxidation; the heating element 1 is fixed on the cover plate 3 , There are four holes with nuts on 3, six holes on 2, and the upper two holes are embedded with nuts, 4 has left and right extending bottom edges and downward extending plates, and two screw holes are punched on the edges, extending There are two punching holes on the board; in terms of spatial distribution, 4 is on top, heating element 1 is close to heat conducting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com