Conical-face spray nozzle without blockage or air resistance and method for forming conical-face aerial fog

A technology of cone surface and nozzle, applied in the direction of spray device, spray device, liquid spray device, etc., to avoid blockage, increase effective use surface, and facilitate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

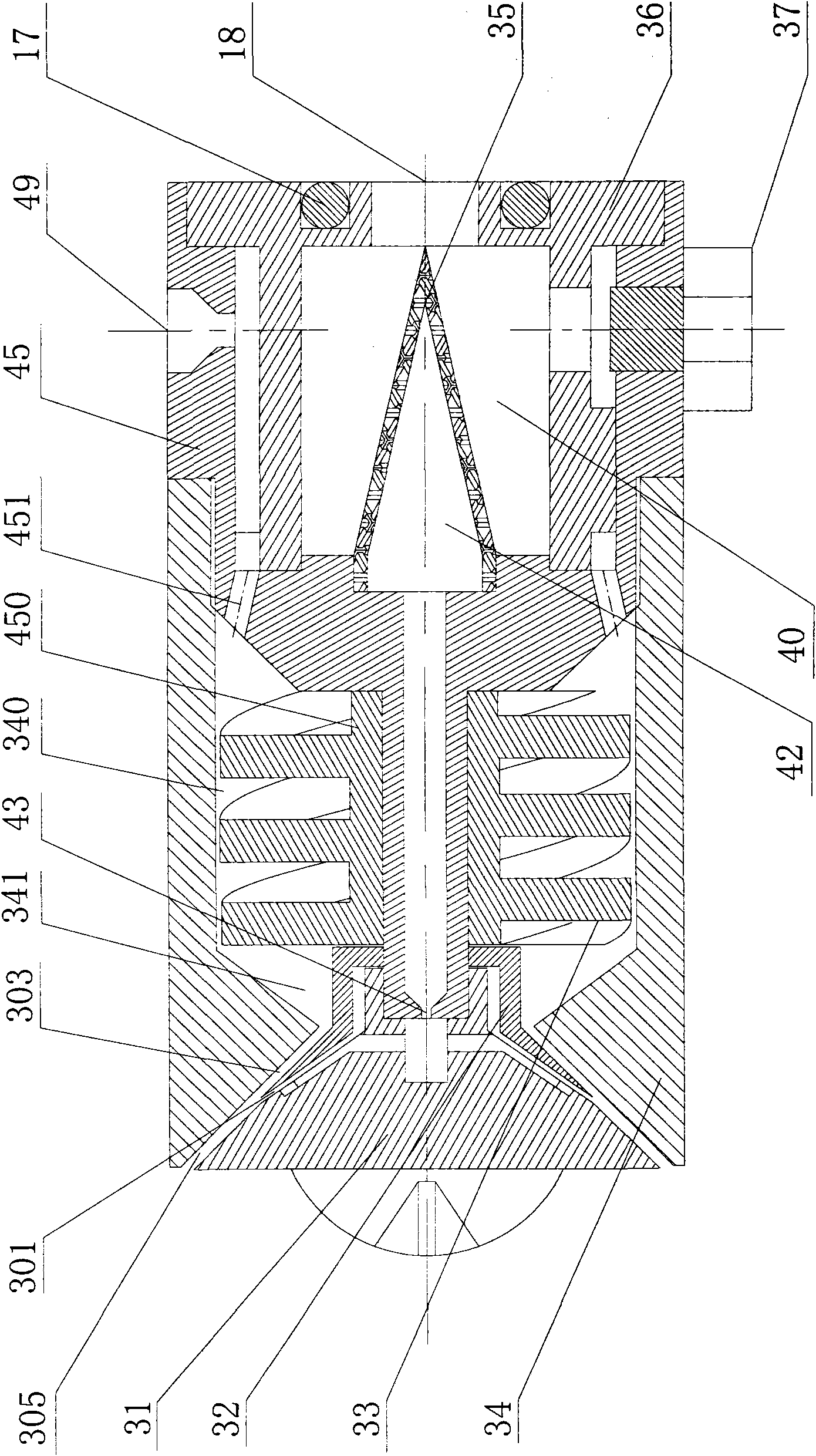

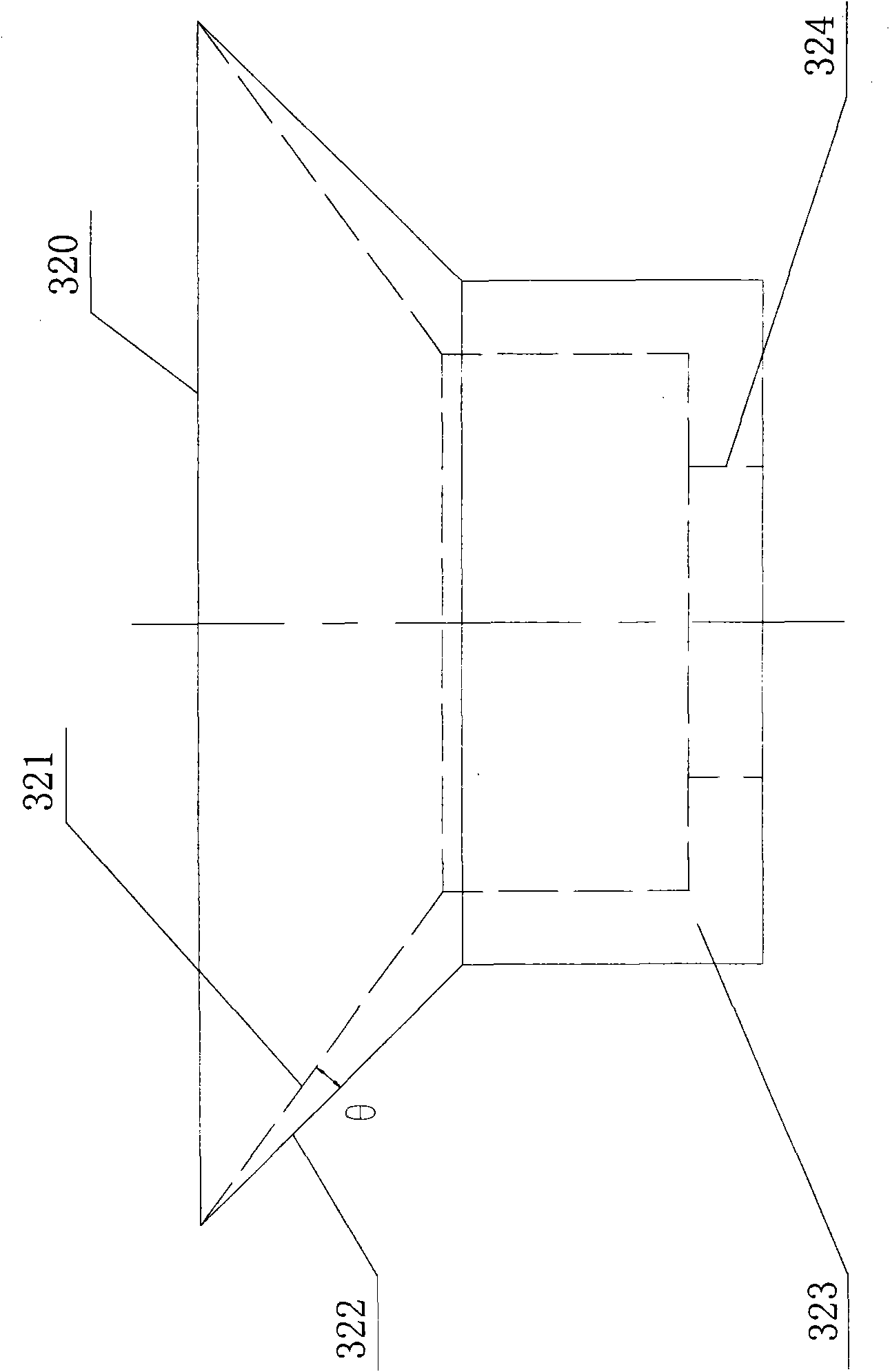

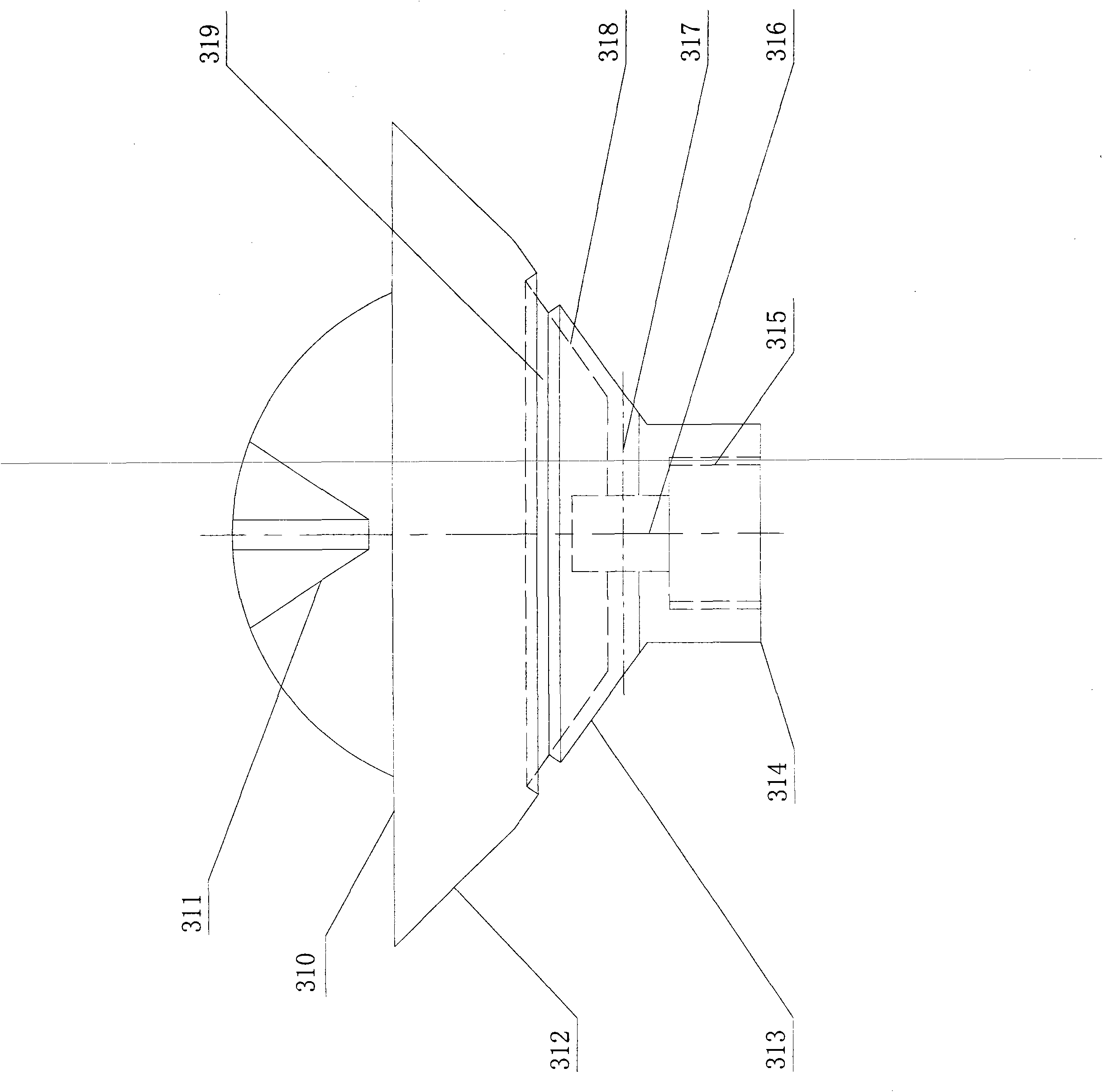

[0046] The present invention proposes a non-clogging, non-air-blocking conical aerosol nozzle and a conical aerosol forming method, the aerosol nozzle includes a fluid mixing injector, the injector is formed with a conical first fluid slit, A conical second fluid slit and a conical mixed jet slit, the first fluid slit and the second fluid slit are spaced apart at a certain angle and converge at the end to form the mixed jet slit, the second The first fluid and the second fluid are mixed and atomized in the mixing jet slit, and ejected along the mixing jet slit with a conical surface. Related to the aerosol nozzle, in the conical aerosol forming method of the present invention, the aerosol nozzle is formed with a fluid mixing injector, and the injector is formed with a first fluid slit and a second fluid slit all in the shape of an inverted cone. The slit and the mixed jet slit, the first fluid slit and the second fluid slit are spaced apart at a certain angle and merged into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com