Prebaked anode carbon block structure of aluminum electrolysis cell

A technology of anode carbon block and pre-baked anode is applied in the field of aluminum electrolytic cell pre-baked anode carbon block structure, which can solve the problems of high processing cost, large contact voltage drop between iron and carbon, large power consumption, etc. and utilization rate, reduce production power consumption, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

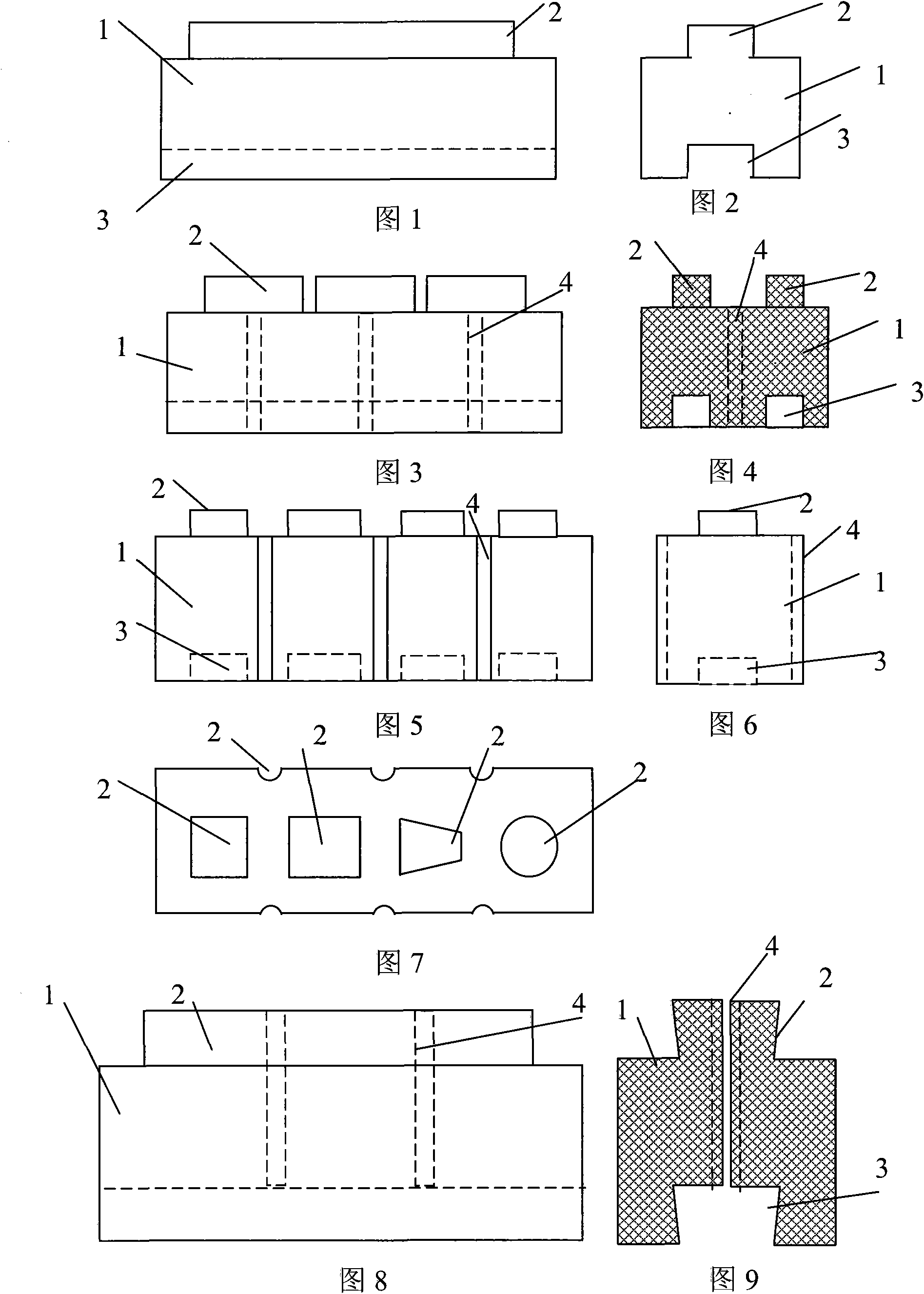

[0036] Embodiment 1: (as figure 1 , figure 2 Shown) an anode carbon block (1) with a prebaked anode carbon block structure for an aluminum electrolytic cell has a convex platform (2) on the upper part, and a concave groove (3) is formed on the bottom of the anode carbon block (1) upwards. The structural dimensions of the convex platform (2) and the concave groove (3) can make the upper and lower carbon blocks (1) interspersed and snap-fit connected on the electrolytic cell, and the convex platform (2) and the groove (3) along the The carbon blocks are arranged in the lengthwise direction.

Embodiment 2

[0037] Embodiment 2: (as image 3 , Figure 4 Shown) an anode carbon block (1) with a prebaked anode carbon block structure for an aluminum electrolytic cell has a convex platform (2) on the upper part, and a concave groove (3) is formed on the bottom of the anode carbon block (1) upwards. The size, shape and number of the convex platform (2) and the concave groove (3) can be designed and constructed according to the size of the anode carbon block (1) and the current distribution density and current intensity of the anode carbon block (1), In this embodiment, there are six convex platforms (2) and concave grooves (3) corresponding to each other up and down, which are divided into two rows and equally spaced. The middle structure of the anode carbon block (1) has a vent hole (4) connected up and down, which is used to discharge volatile gas when the anode carbon block (1) is roasted and discharge the lower surface of the anode carbon block (1) and the electrolyte electrode on ...

Embodiment 3

[0038] Embodiment 3: (as Figure 5 , Figure 6 and Figure 7 Shown) the upper part of an anode carbon block (1) with a prebaked anode carbon block structure for an aluminum electrolytic cell has a convex platform () 2, and the bottom of the anode carbon block (1) is upwardly configured with a concave groove (3), which The plane projection of the structural shape of the convex platform (2) can be rectangular, trapezoidal, or circular; on the outer surface of the anode carbon block (1), there are semicircular row rows interpenetrating with the upper and lower surfaces of the anode carbon block (1). The air hole (1) channel is used to form a circular exhaust hole (4) channel that penetrates up and down after two adjacent carbon blocks (1) are assembled on the electrolytic cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com