Oilfield underground high-pressure fluid-driven spinning horizontal perforating device and application thereof

A high-pressure fluid and perforating device technology, which is used in underwater drilling, wellbore/well components, earth-moving drilling, etc., can solve the problems of limited driving force of high-pressure hose, short horizontal well hole distance, troublesome work, etc. The effect of labor intensity, improving work efficiency and improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

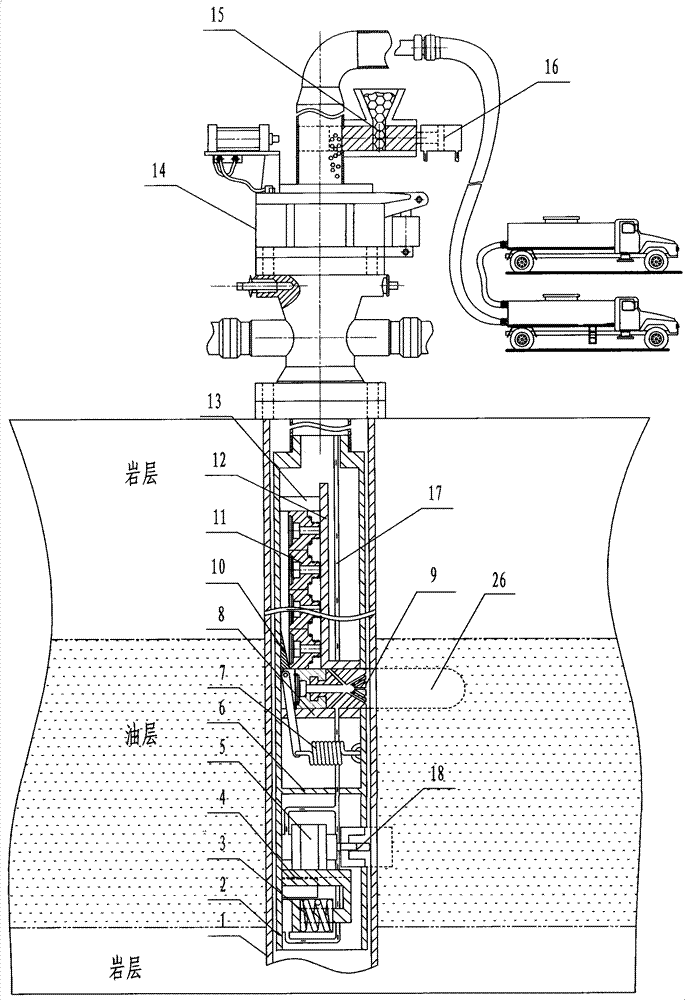

[0025] like figure 1 As shown, the spin horizontal drilling device driven by high-pressure fluid in the oil field is mainly composed of a surface high-pressure water system, a drilling-production drilling mechanism, and a casing drilling mechanism. In this embodiment, the high-pressure fluid is high-pressure water, and the surface high-pressure The fluid system adopts the surface high-pressure water system, and the drilling and production drilling mechanism and the casing drilling mechanism are installed in the high-pressure chamber in the well 1. The surface high-pressure water system communicates with the high-pressure chamber. After forming; the surface high-pressure water system is composed of a wellhead, a lifting and centralizing mechanism 14, an abrasive adding device 15, and a pneumatic pump 16. The lifting and centralizing mechanism 14 is composed of inner and outer two-layer casings and lifting arms. connection, the casing lower end of the lifting and righting mechan...

Embodiment 2

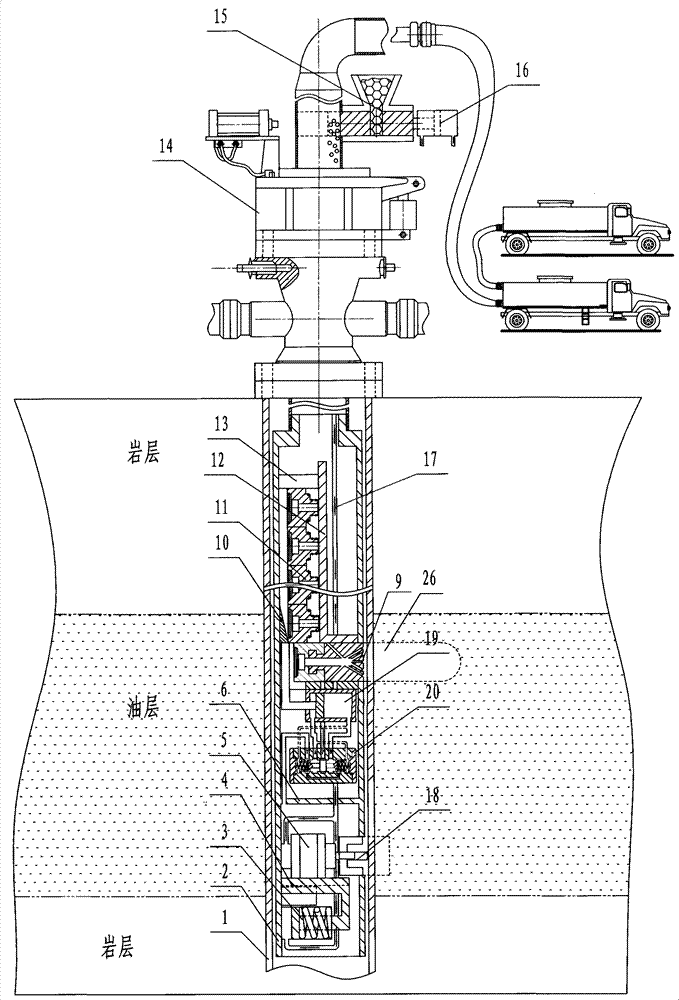

[0031] figure 2 Provide the structural representation of embodiment 2, as shown in the figure, this embodiment and figure 1 The difference of the illustrated embodiment is that the push-feed mechanism utilizes the double-acting hydraulic cylinder 19 and the automatic reversing valve 20 to replace the feed spring group 7 and the spring group fixing seat, and the hydraulic rod of the double-acting hydraulic cylinder 19 and the horizontal guide hole The inner drive guide block 11 is connected, and the drive guide block 11 is embedded in the base of the high-pressure jet spin spray head 9 . Other structures are the same as in Embodiment 1.

[0032] The first stage of the working process of this embodiment is the same as that of Embodiment 1. In the second stage, the double-acting hydraulic cylinder 19 and the automatic reversing valve 20 push and drive the guide block 11 and the high-pressure jet spin nozzle 9, using the principle of high-pressure water jet , Utilize high-press...

Embodiment 3

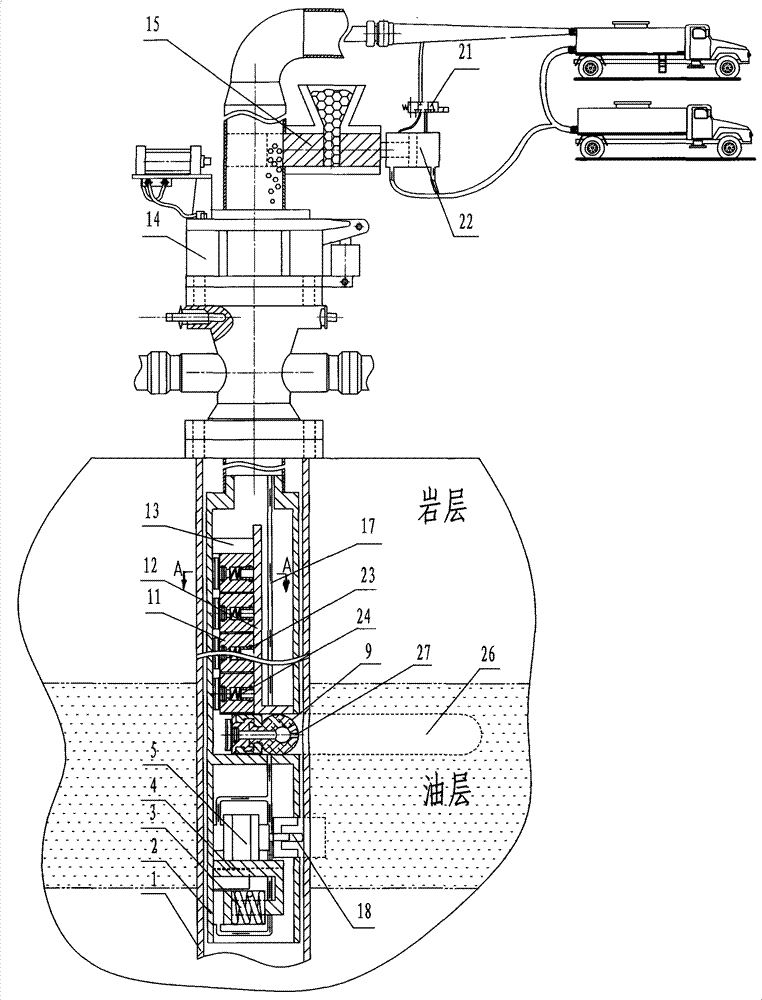

[0034] image 3 A schematic structural diagram of Embodiment 3 is provided. As shown in the figure, this oilfield downhole high-pressure fluid-driven spin horizontal drilling device is mainly composed of a surface high-pressure water system, a drilling-production drilling mechanism, and a casing drilling mechanism. The surface high-pressure water system consists of a wellhead, a lifting and centralizing mechanism 14, an abrasive adding device 15, a water pump 22, and an electromagnetic control valve 21. The abrasive adding device 15 is connected to the water pump 22 through a horizontal pipe, and the water pump 22 is connected to the electromagnetic control valve 21. The electromagnetic control valve 21 is The two-position three-way solenoid valve, the solenoid control valve 21 is connected with the high-pressure pipeline from the high-pressure water injection truck, and the water pump 22 is connected with the pipeline from the oil field operation water tank truck.

[0035] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com