Differential frequency multiplication rotary coder

A rotary encoder and differential technology, applied in the field of differential frequency multiplication rotary encoder, can solve the problems of high ambient temperature, no good ground wire, large vibration of the transmission drum and transmission mechanism, etc., and achieve high-precision measurement and direction identification and debugging. The effect of easy and simple calibration and long data transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

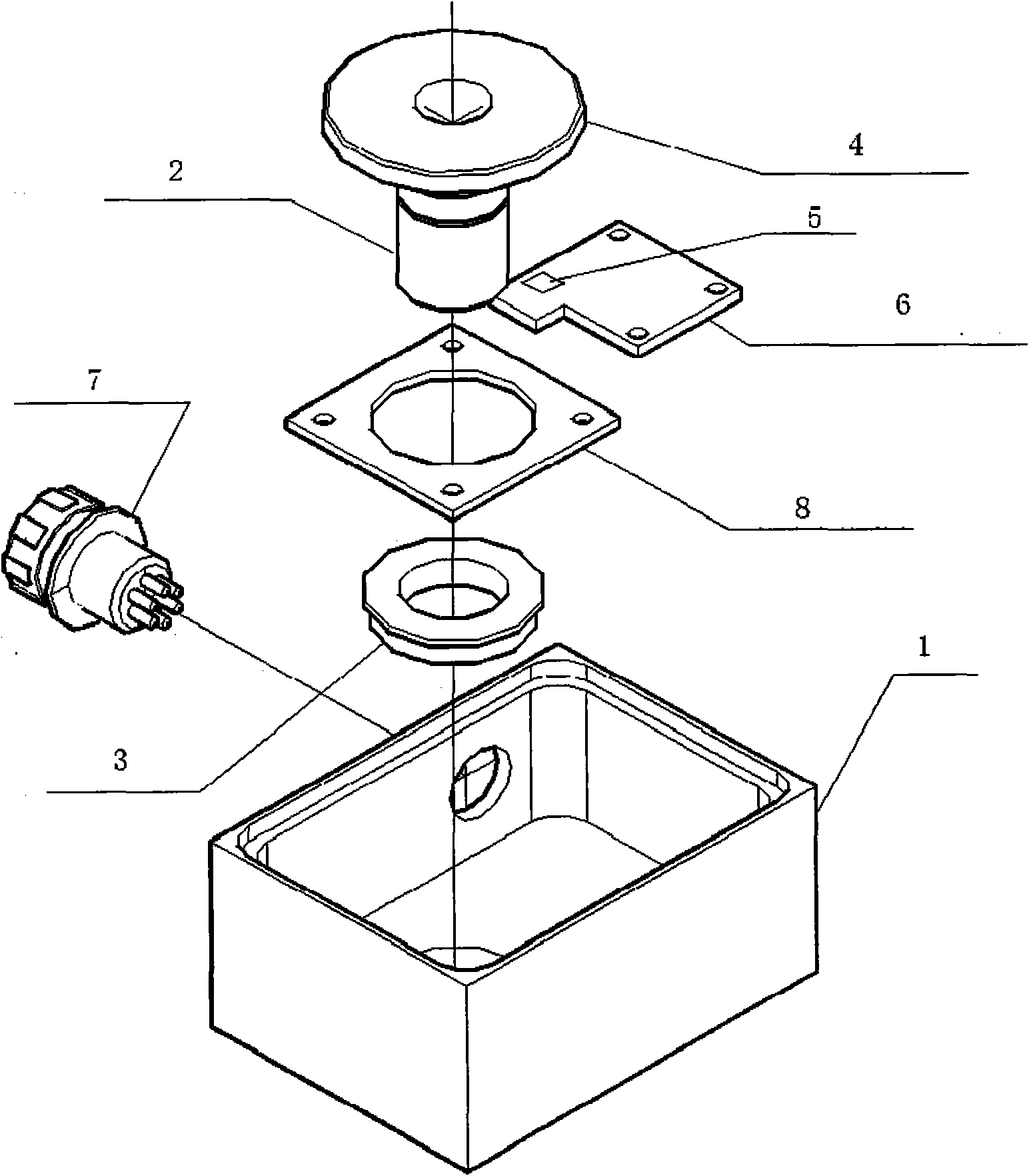

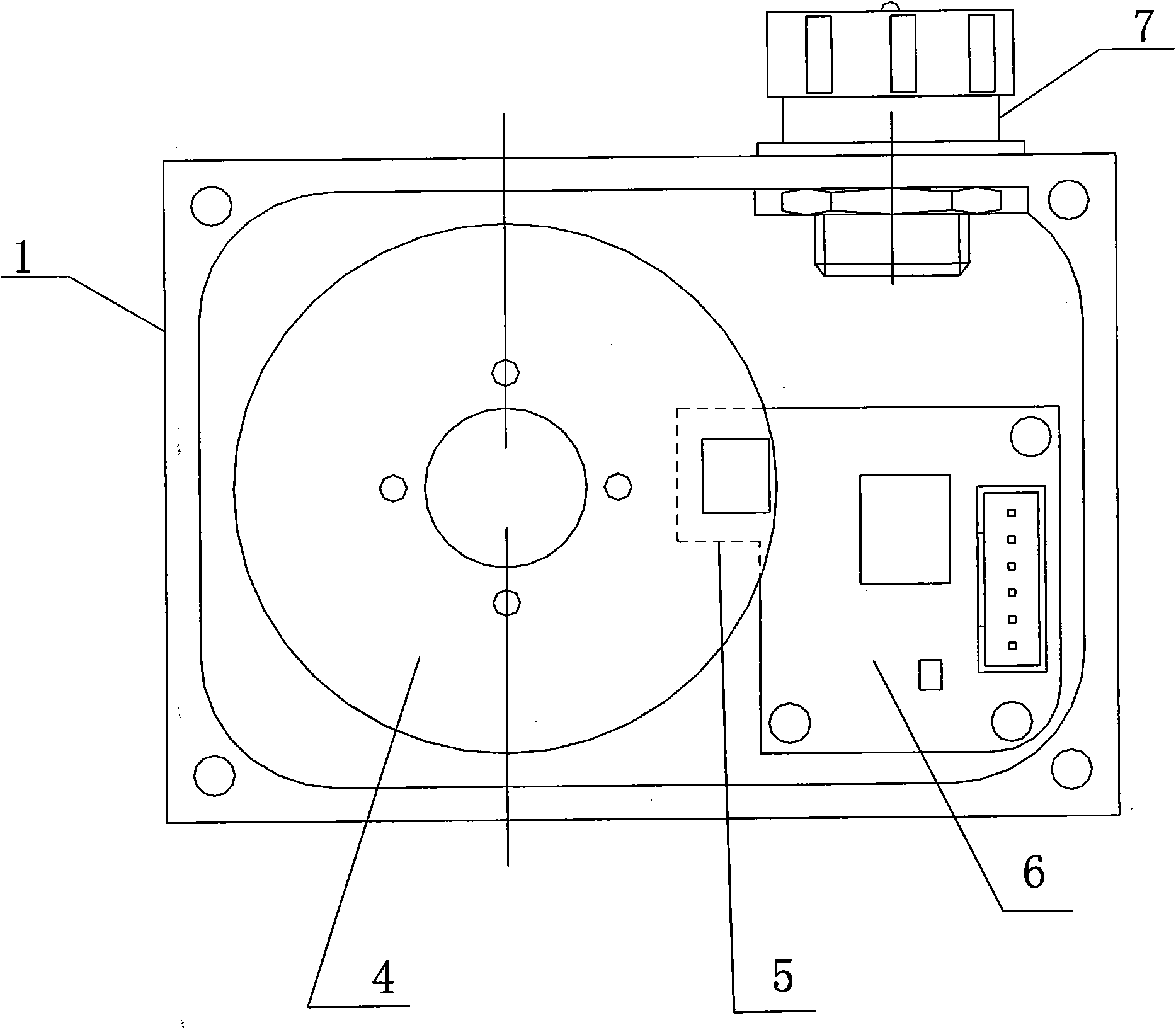

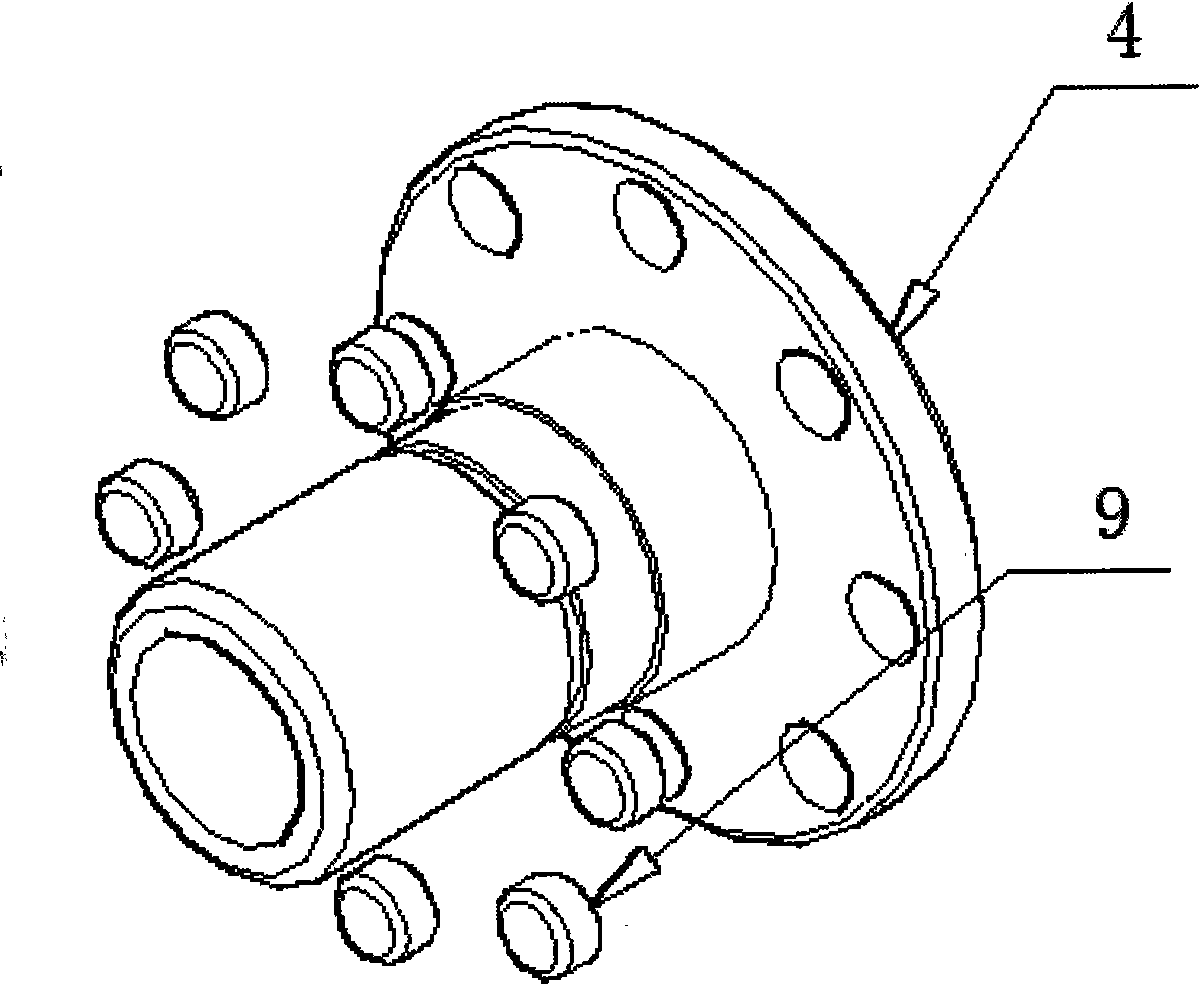

[0018] figure 1 , figure 2 , image 3 It includes a housing 1, the housing 1 is provided with a connecting shaft 2, one end of the connecting shaft 2 is installed in the bearing 3, and the other end is connected with the pulse code disc 4; the housing 1 is also provided with a dual-channel Hall The chip 5 and the differential conditioning circuit 6 are connected to the aviation plug 7, and the dual-channel Hall chip 5 corresponds to the pulse code disc 4. The connecting shaft 2 is connected with the bearing 3 through the bearing fixing piece 8 . Several magnetic steels 9 are evenly distributed on the circumference of the pulse code disc 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com