Apparatus for heating pattern frame

A kind of equipment and frame technology, applied in the field of heating equipment, can solve the problems of limited rapid heating, heating equipment 10 is not equipped with a specific cooling device, and it is difficult to cool quickly and uniformly, so as to achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

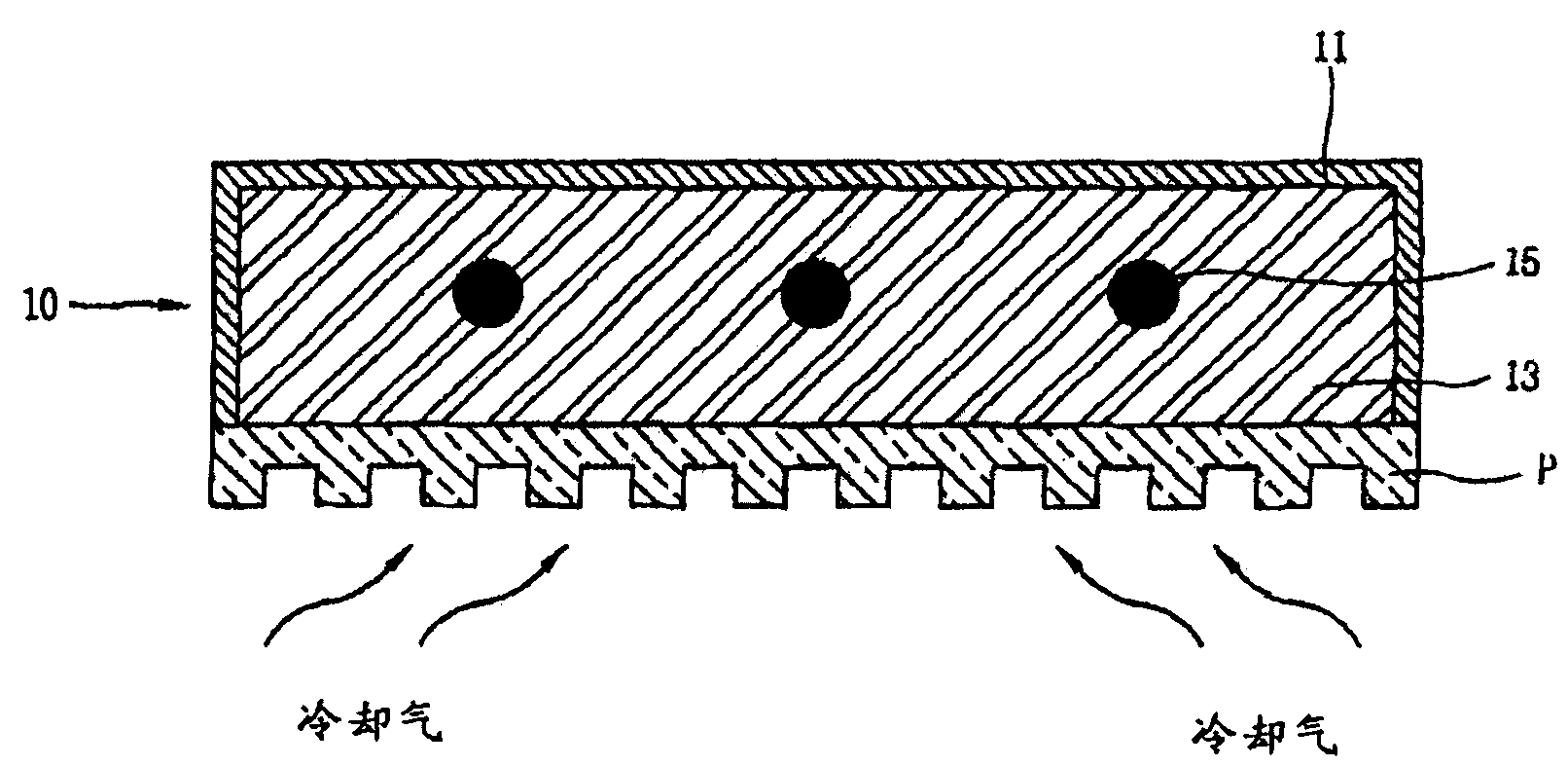

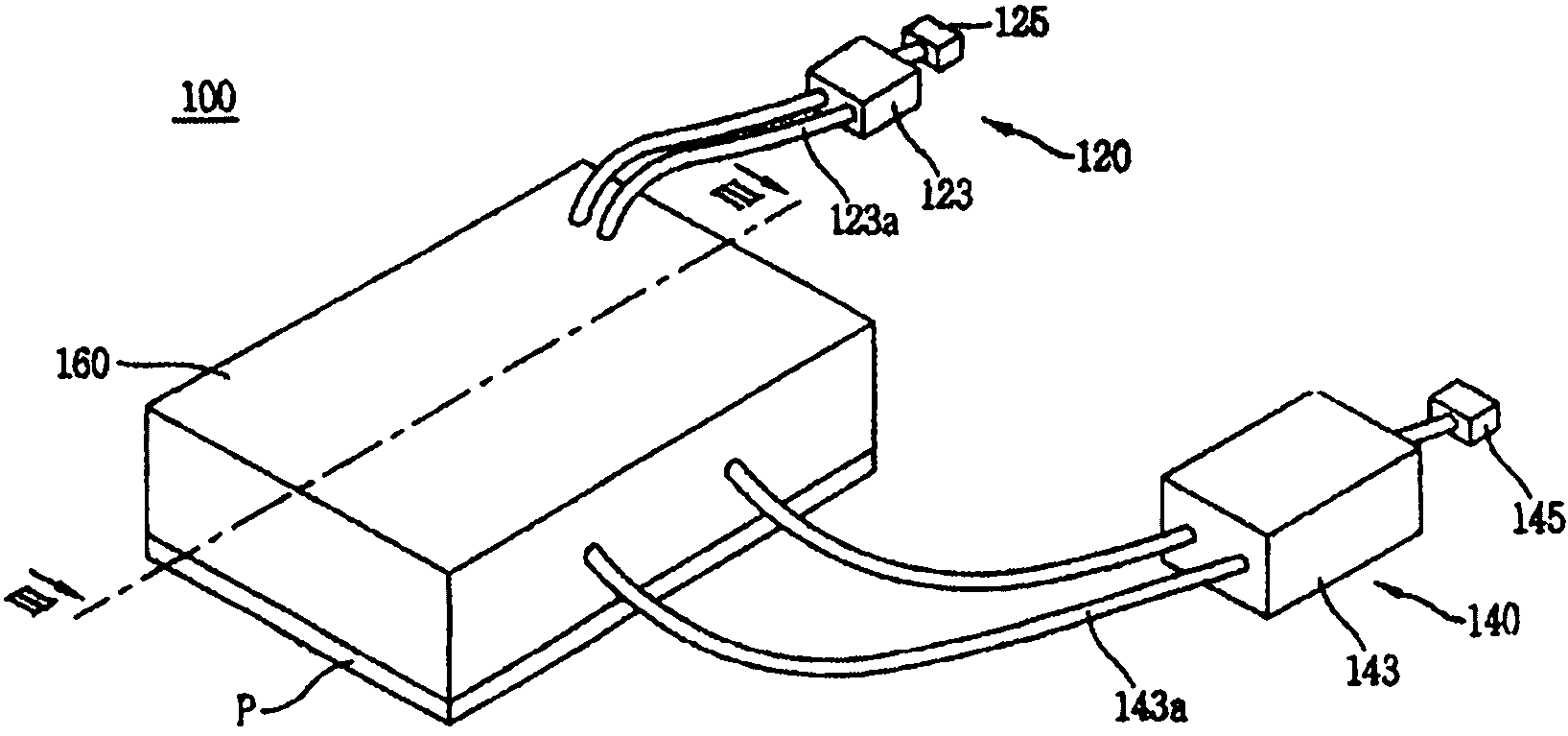

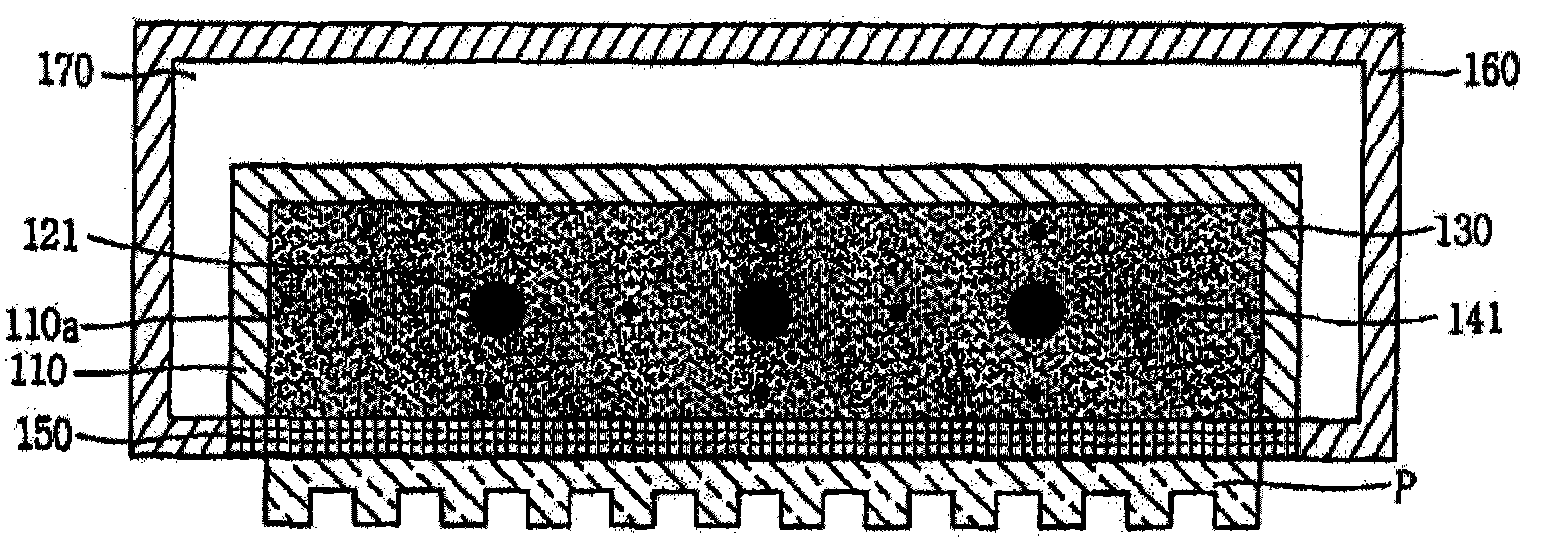

[0037] Hereinafter, an apparatus for heating a pattern frame according to a preferred embodiment of the present invention will be described in detail, examples of which are shown in the accompanying drawings.

[0038] figure 2 is a perspective view showing an apparatus 100 for heating a pattern frame according to a first embodiment of the present invention.

[0039] see figure 2 , the device 100 for heating a pattern frame includes: a cover 160 having a pattern frame P mounted to one surface thereof and enclosed internal components; a heating unit 120 electrically connected to the internal components in the cover 160; and a cooling unit 140 , which communicates with internal components within the cover 160 .

[0040] The pattern frame P is heated by the internal components of the cover 160 and the heat generating unit 120, and then contacts the glass plate G on which the film is formed ( Figure 4 ). To bring the pattern frame P into contact with the glass sheet G, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com