Solid-liquid separation treatment equipment

A treatment equipment, solid-liquid separation technology, applied in the field of sanitary equipment, can solve the problems of affecting the efficiency of microbial fermentation treatment, unable to collect urine, unavoidable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation and safety evaluation of embodiment 1 microbial bacterial agent

[0031] The medium formula used to cultivate Saccharomyces cerevisiae ZL-1011 strain with the preservation number CGMCC No.2018: 10.0 grams of peptone, 1.0 grams of yeast extract, 5.0 grams of molasses, 1.0 liter of water, natural pH, sterilized at 115 degrees 30 minutes. Shake the culture at 25-28° C. on a shaker (200 rpm) for 36-48 hours. Take 1 kg of sterilized sawdust and mix it evenly with the fermented bacteria liquid, and dry it at room temperature, which is the yeast inoculant.

[0032] The preservation number is Bacillus megaterium ZL-1010 strain CGMCC No.1724, the preservation number is Bacillus subtilis ZL-1007 strain CGMCC No.1725, the preservation number is Bacillus sphaericus ZL-1008 strain CGMCC No.1726, and the preservation number is 6 The strains were cultured in liquid respectively, and the medium formula used was: 10.0 grams of peptone, 1.0 grams of yeast extract, 5.0 gram...

Embodiment 2

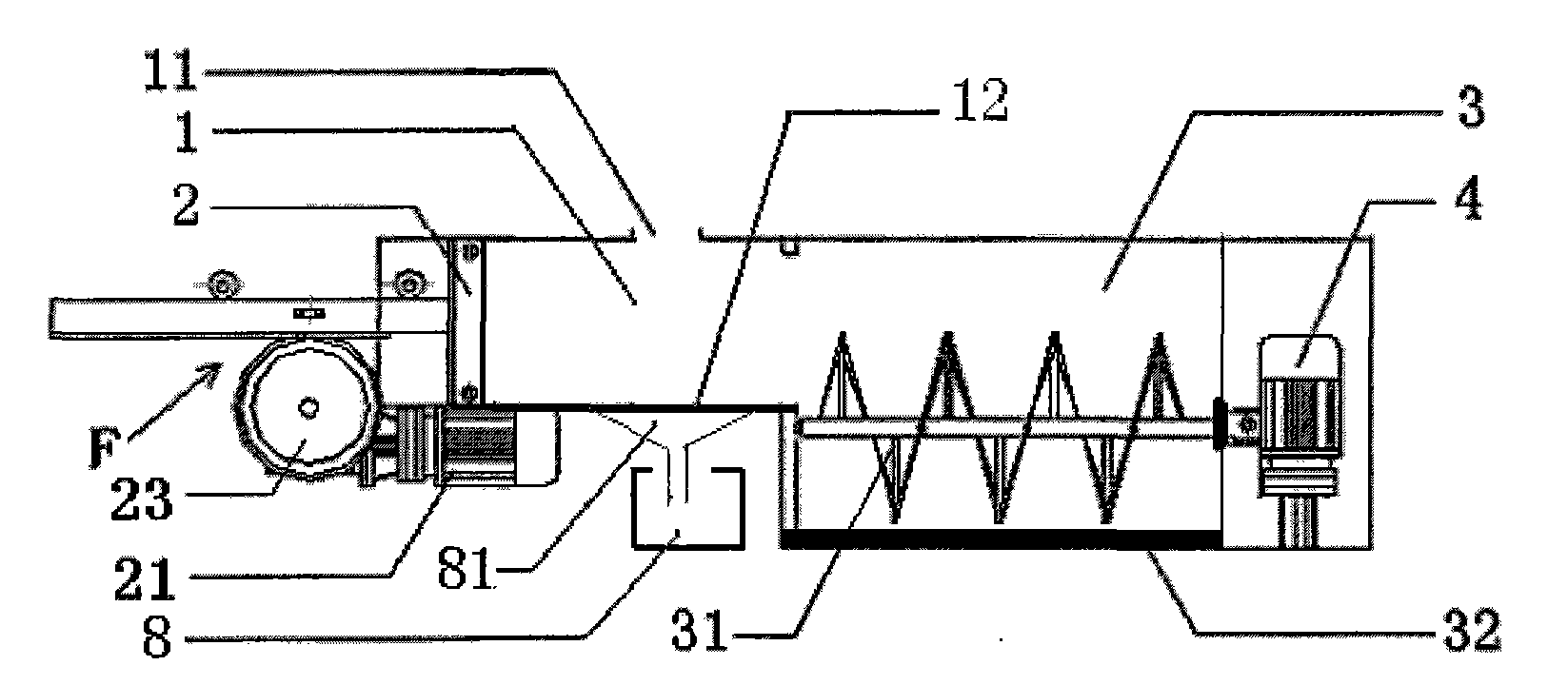

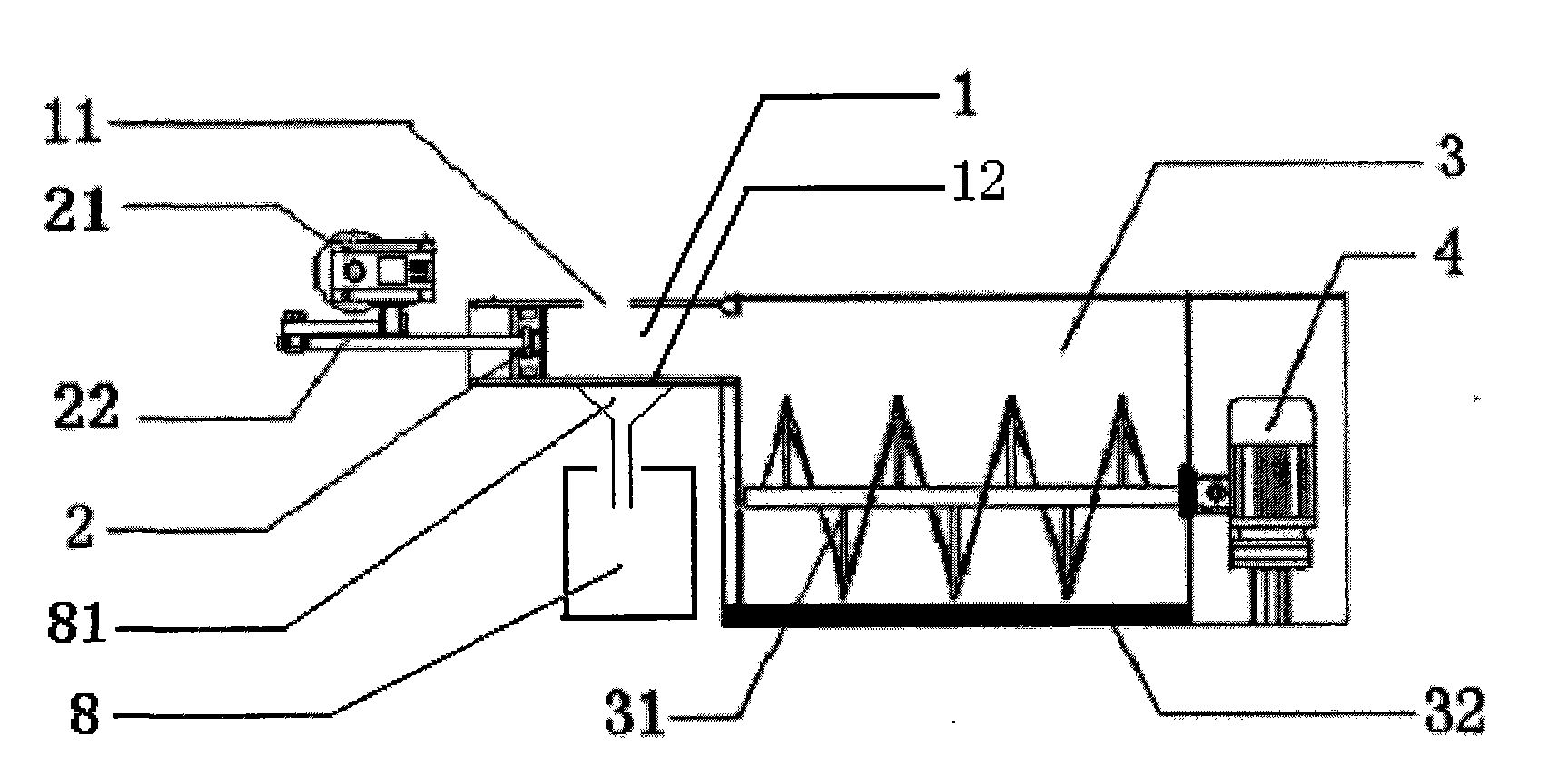

[0037] Embodiment 2 is used for the excrement and urine treatment equipment of ecological non-flush toilet

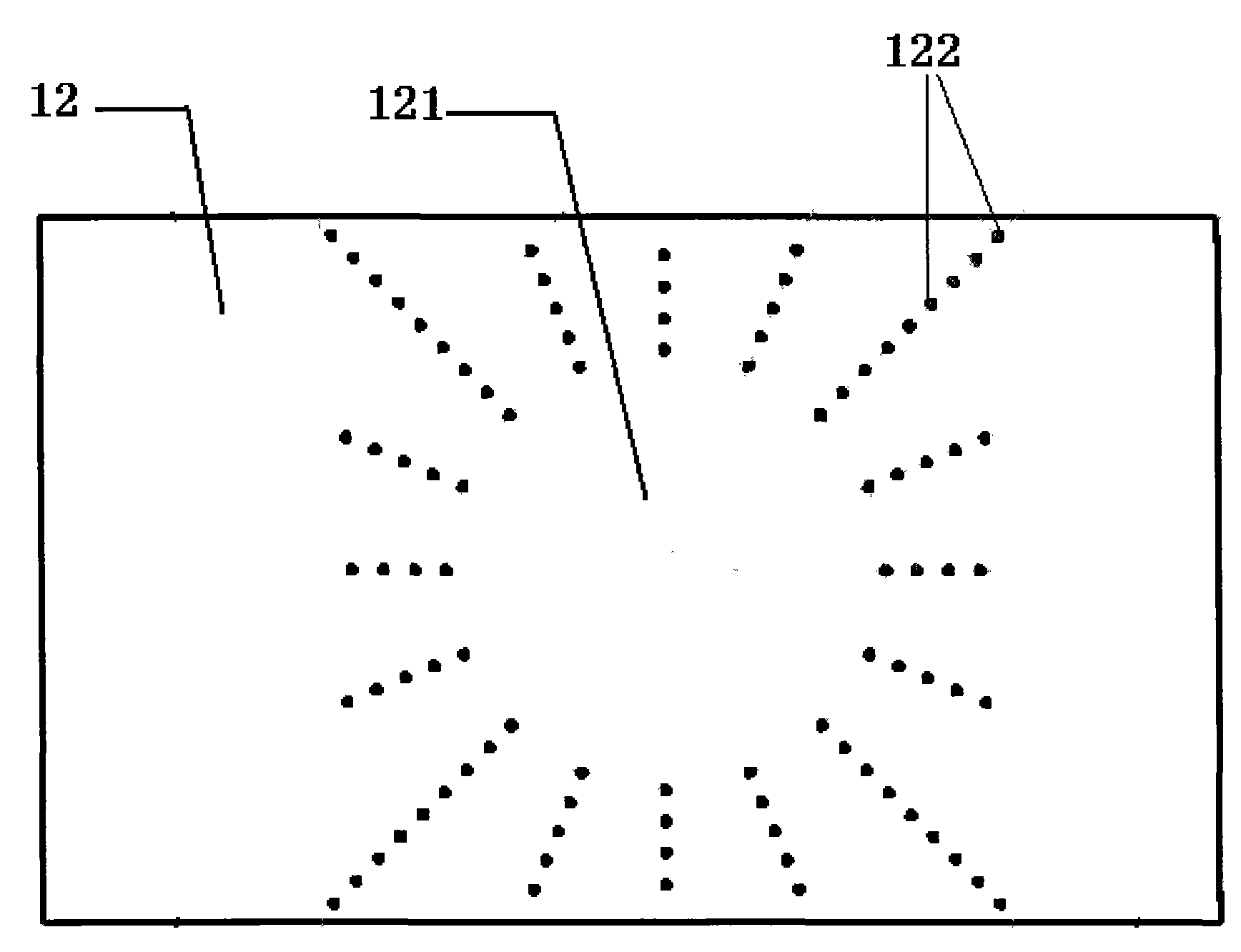

[0038] Such as Figure 1-4 As shown, the excrement and urine treatment equipment for ecological flush-free toilets includes a temporary feces storage container 1, a scraping device 2, a fermentation container 3, a liquid storage container 8 and a mechanical transmission device 4, and is characterized in that the temporary feces storage container 1. The upper part has an opening 11, which can correspond to the movable baffle plate 51 at the bottom of the squatting pan 5; the bottom surface 12 of the temporary feces storage container 1 is facing the area 121 of the opening 11 and is provided with holes 122 around it. The liquid can pass through the hole 122 and flow through the catheter 81 into the liquid storage container 8 below the temporary feces storage container 1; the temporary feces storage container 1 communicates with the fermentation container 3, and the tempor...

Embodiment 3

[0041] Embodiment 3 Ecological free flush toilet and its application

[0042] Such as Figure 1-4 As shown, the ecological flush-free toilet includes a squatting toilet room 100 located on the base surface 7 and a treatment chamber 200 located under the base surface 7. It is characterized in that the squatting toilet room 100 is equipped with a squatting toilet 5, and the squatting toilet 5 Closet 5 is installed above base surface 7; And, the excrement and urine treatment equipment described in embodiment 2 is installed in the treatment chamber 200, wherein the temporary excrement storage container 1 top has opening 11, and it is connected with the movable stop of squatting pan 5 bottoms. Plate 51 corresponds.

[0043] In this ecological flush-free toilet, there is a photoelectric sensor 6 in the squatting room 100, and the photoelectric sensor 6 is connected with the electric control device in the excrement and urine treatment equipment, and it is used for sensing activitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com