Plate shearing machine

A technology of shearing machine and frame, which is applied in the direction of shearing device, shearing machine equipment, metal processing equipment, etc., and can solve the problems of failure to meet the use requirements, low control accuracy, and cutting off the intermediate material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

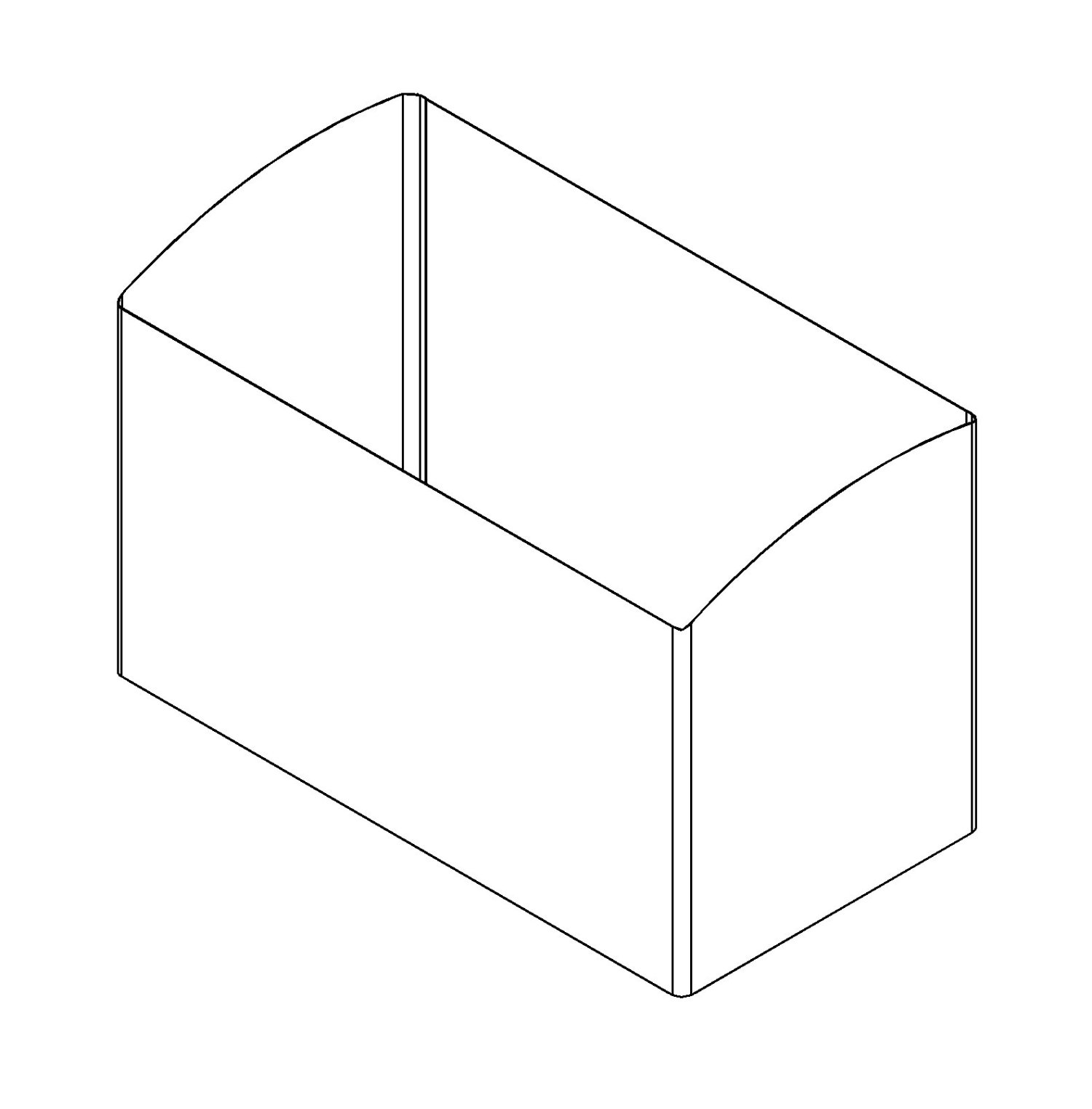

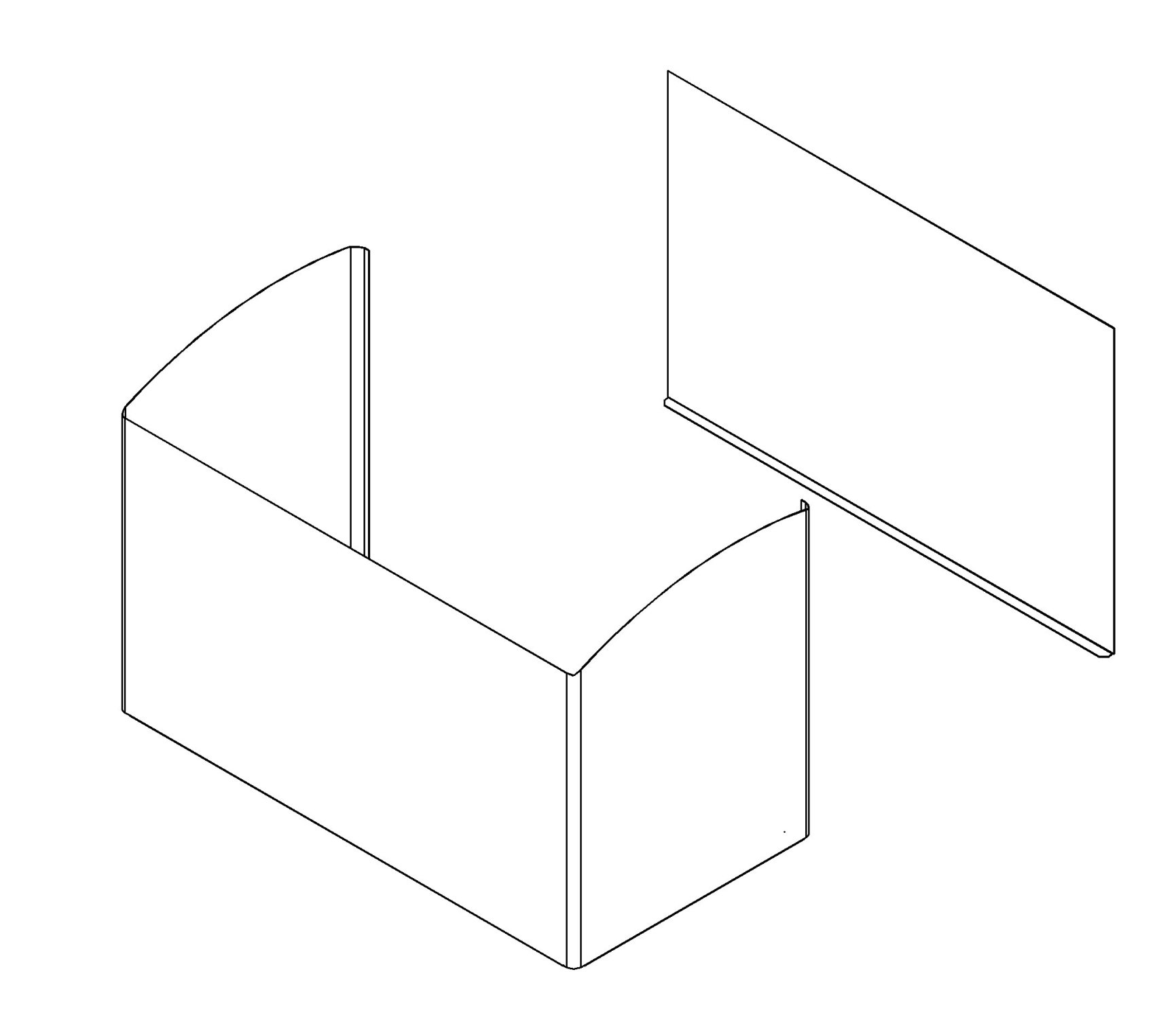

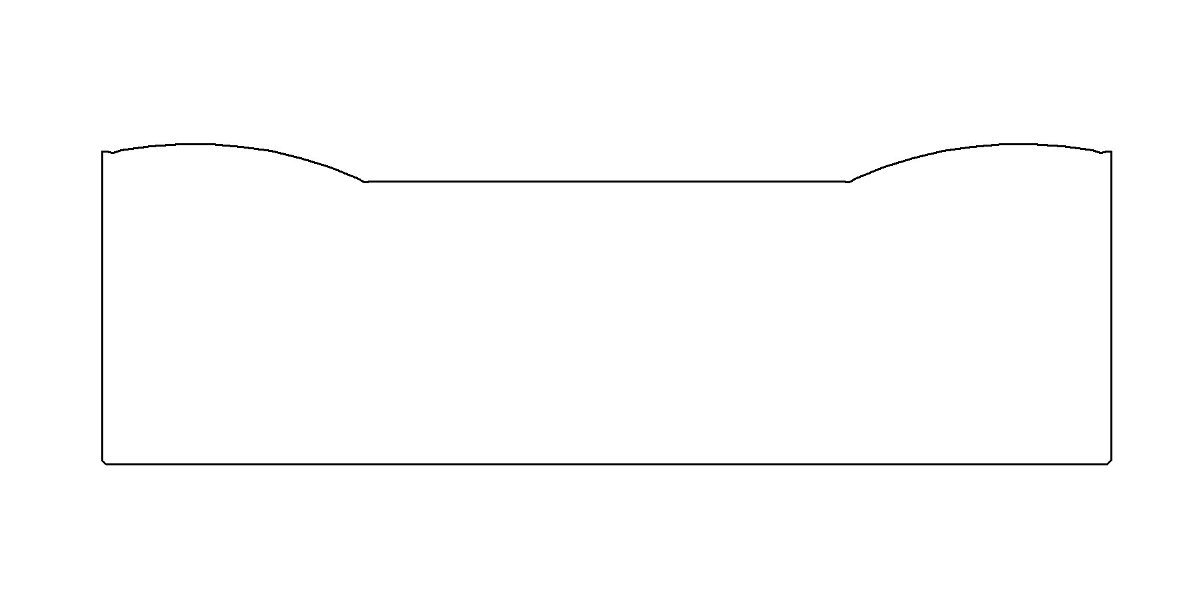

[0017] A shearing machine, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , including a frame 1 and a slider 2 installed on the frame 1 through a linear guide rail pair 14, a lower scissor 3 is fixed on the frame, an inclined upper scissor 4 is fixed on the slider, and the upper scissors and the lower scissors are staggered from each other, The blade surfaces are flush with each other; multiple (two, three or more) nuts 5 are fixed on the top of the slider, and each nut is equipped with a longitudinal screw 6, and the top of the screw can change the transmission The bevel gear steering boxes 7 in the direction, each bevel gear steering boxes are connected by joint shafts 15, and one of the bevel gear steering boxes is connected with the servo motor 8. The bevel gear steering box can transform the rotation in the horizontal direction into the rotation in the vertical direction. It is an existing technology, and it can be only two bevel gears meshing with each other at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com