Mobile operation platform device for ship

A working platform and mobile technology, applied in the direction of ship cleaning device, slipway, hoisting device, etc., can solve the problems such as the need for ship maintenance and cleaning operations, and the increase in construction costs, so as to save operating time and reduce costs. Construction costs and the effect of ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 is a single-track mobile working platform device for working in the cargo hold of a bulk carrier.

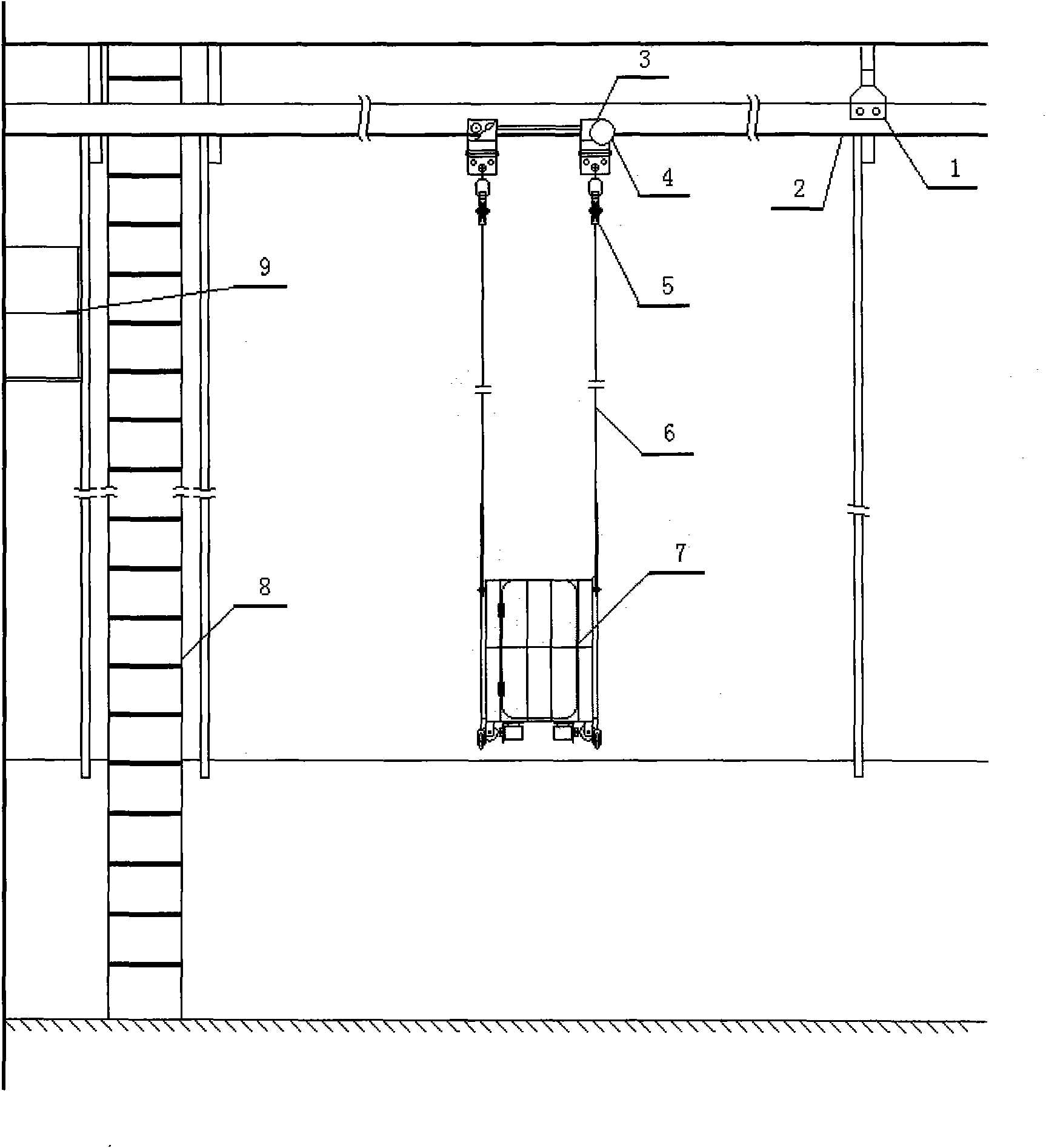

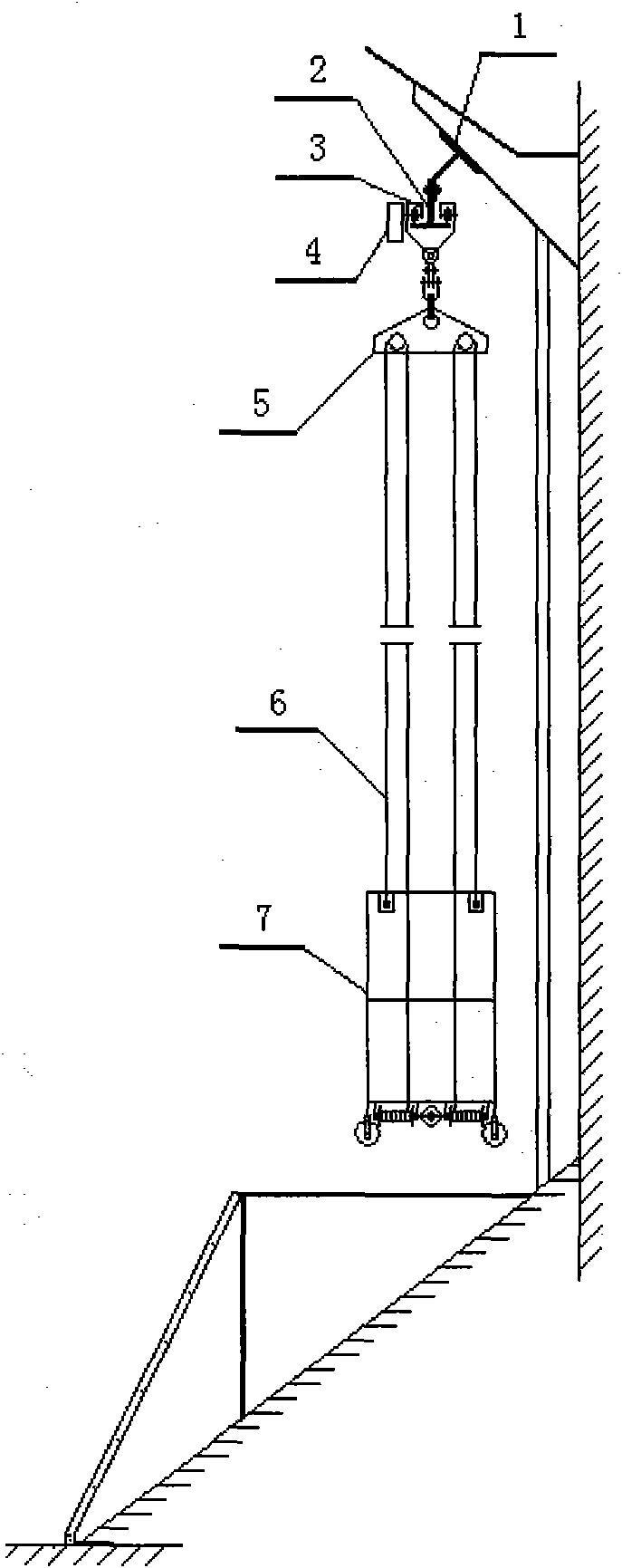

[0027] Such as figure 1 and figure 2 As shown, the main structure of the single-track mobile work platform device is composed of the connecting base (1), driving track (2), hanging basket driving (3), driving device (4), connecting rigging (5), lifting mechanism (6), work hanging basket (7), working ladder (8), working platform (9) and other components. in:

[0028] Connecting base (1): It is a group of connectors fixedly installed on the roof, wall or other hull components of the ship's cargo hold, and is used to install components such as driving rails.

[0029] Driving track (2): It is a group of beam frame members installed along the horizontal direction of the working surface and erected on the cargo tank roof, upper bulkhead or rib bracket through the connecting base (1). It provides a passage for the work hanging basket (7) to move horizontally al...

Embodiment 2

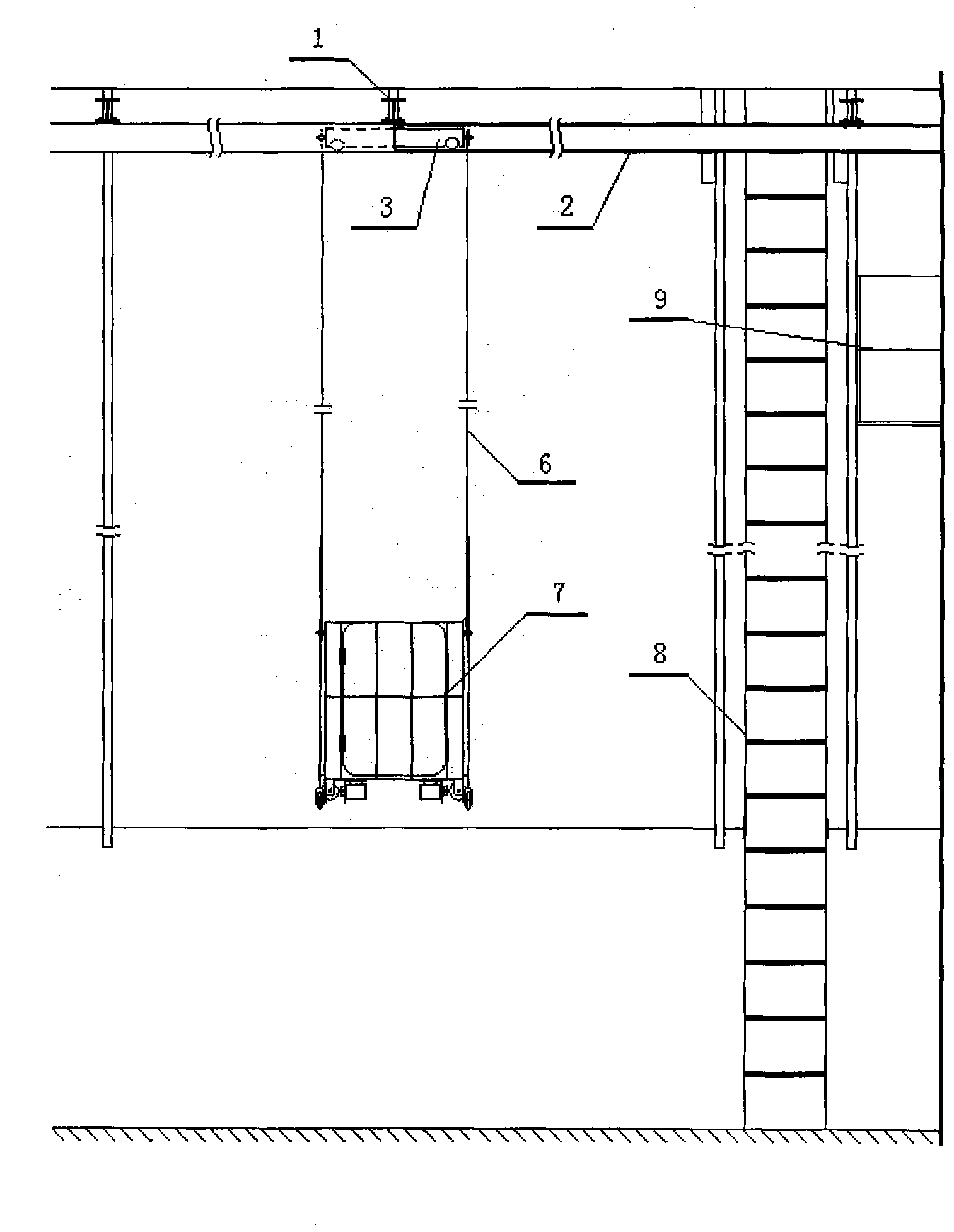

[0049] Embodiment 2 is a double-track mobile working platform device mainly used in the cargo hold of a single-hull bulk carrier.

[0050] Such as Figure 3 ~ Figure 4 As shown, its main structure is composed of connecting base-cantilever frame (1), driving track (2), hanging basket driving (3), lifting mechanism (6), working hanging basket (7), working ladder (8), Working platform (9) and other components are formed. in:

[0051] Cantilever frame (1): One end is fixedly connected to the rib or bulkhead plate at the height of the cargo hold wall and other places, and the other end can be suspended in the air to erect the cantilever beam structure. It is one of the main components of the device, which can be made of I-beam or other materials with considerable strength, and can be welded or connected to the above-mentioned components with fasteners such as bolts.

[0052] Driving track (2): It is a group of beam frame components connected to the cantilever frame (1) and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com