Sludge drying method

A sludge and dryer technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of long process operation time, complicated equipment and process, low sludge moisture content, etc., achieving significant environmental benefits and improving Service life, effect of improving heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

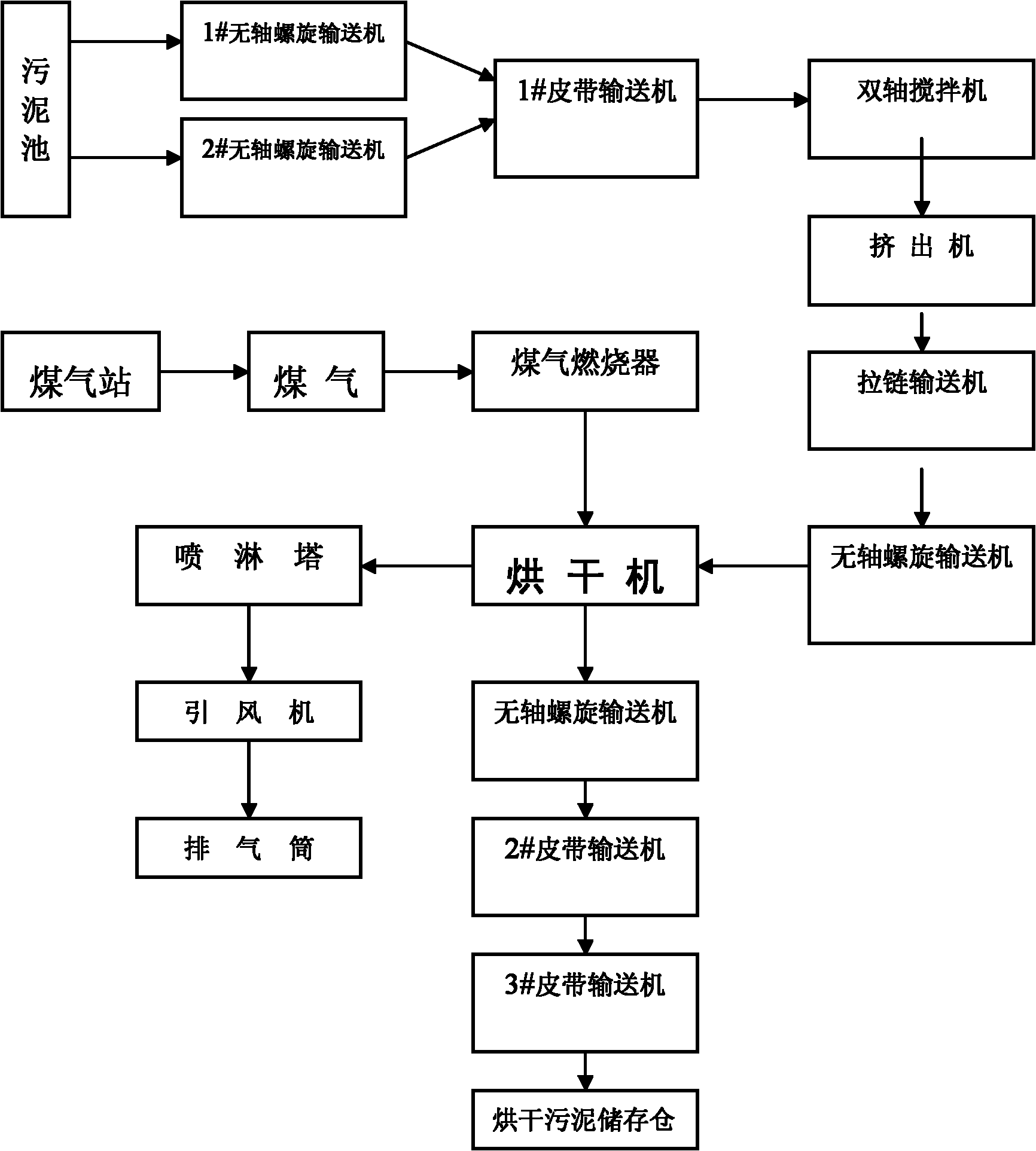

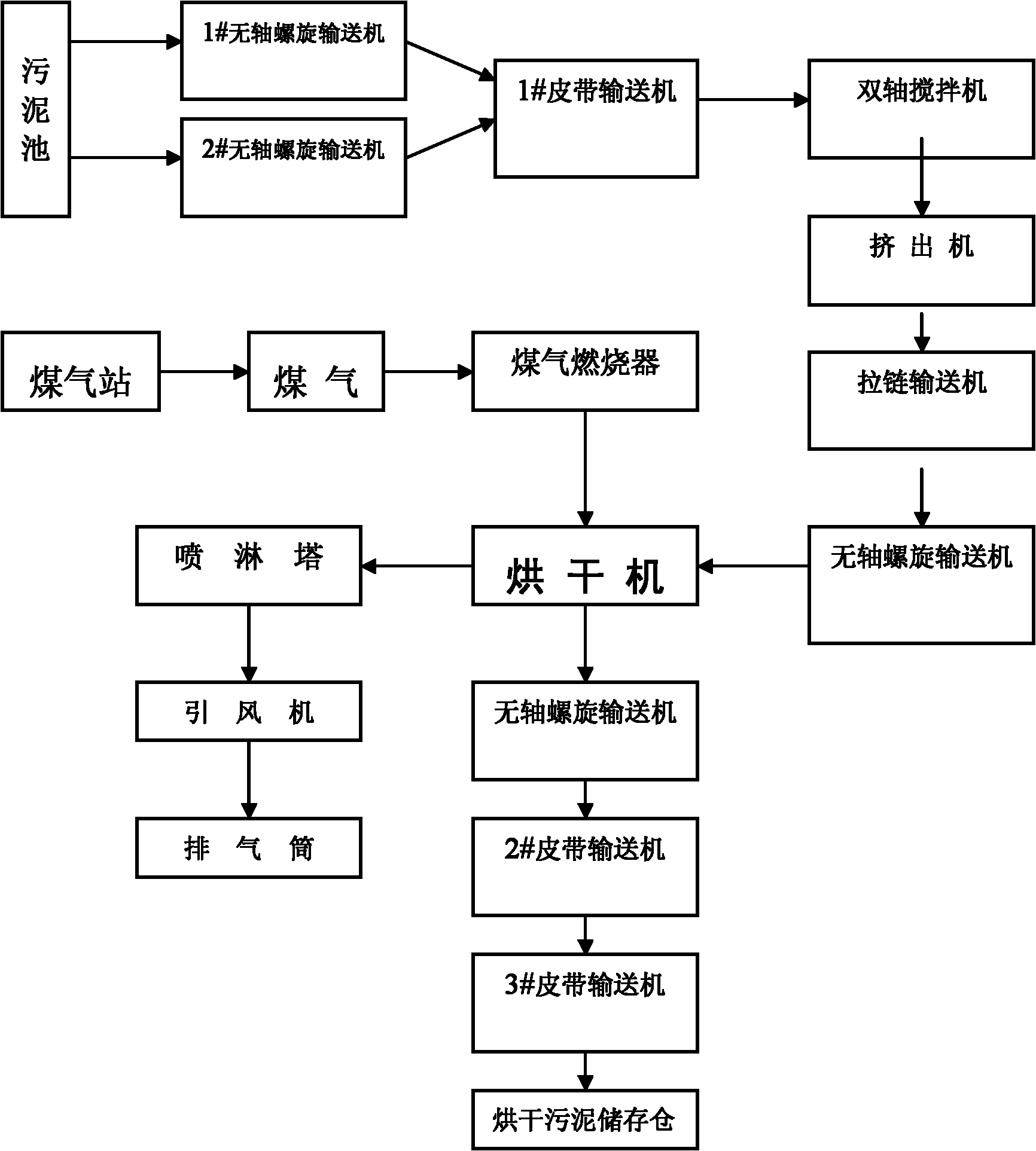

[0030] Such as figure 1 Shown: First use two shaftless screw conveyors (model: WLSS40) to transport the sludge with a water content of 85% in the sludge tank to the belt conveyor (model: B600X158m) for 2 minutes, and then use the belt conveyor (Model: B600X158m) After conveying the sludge for 4 minutes to a twin-shaft mixer ((Model: JLSS40) for 2 minutes, then extruding it through an extruder (Model: JLSS40, output 10t / h), the extrusion time for 2 minutes.

[0031]First use the zipper conveyor (model: GSS250, output 5t / h) to transport the extruded sludge particles to the shaftless screw conveyor (model: LSS250) for 2 minutes, and then use the shaftless screw conveyor to transport the sludge After conveying for 4 minutes, the inclined plate made of 2520 heat-resistant stainless steel plate slides the material into the cylinder space at the feed end along the inclined surface. The rotary drum dryer (model: Φ2.2×30m; 0.6 ~5r / min) for 50 minutes, the inlet temperature of the dry...

Embodiment 2

[0034] First use two shaftless screw conveyors (model: WLSS40) to transport the sludge with a water content of 80% in the sludge tank to the belt conveyor (model: B600X158m) for 1 minute, and then use the belt conveyor (model: : B600X158m) transport the sludge for 5 minutes to a twin-shaft mixer ((model: JLSS40) for 3 minutes and then extrude it through an extruder (model: JLSS40, output 10t / h), and the extrusion time is 1 minute .

[0035] First use the zipper conveyor (model: GSS250, output 5t / h) to transport the extruded sludge particles to the shaftless screw conveyor (model: LSS250) for 1 minute, and then use the shaftless screw conveyor to transport the sludge After being transported for 5 minutes, the inclined plate made of 2520 heat-resistant stainless steel plate slides the material into the cylinder space at the feed end along the inclined surface. The rotary drum dryer (model: Φ2.2×30m; 0.6 ~5r / min) for 60 minutes, the inlet temperature of the dryer is 600°C, and t...

Embodiment 3

[0038] First use two shaftless screw conveyors (model: WLSS40) to transport the sludge with a water content of 90% in the sludge tank to the belt conveyor (model: B600X158m) for 3 minutes, and then use the belt conveyor (model: : B600X158m) transport the sludge for 2 minutes to the twin-shaft mixer ((model: JLSS40) for 1 minute and then extrude it through the extruder (model: JLSS40, output 10t / h), the extrusion time is 3 minutes .

[0039] First use the zipper conveyor (model: GSS250, output 5t / h) to transport the extruded sludge particles to the shaftless screw conveyor (model: LSS250) for 3 minutes, and then use the shaftless screw conveyor to transport the sludge After being transported for 2 minutes, the inclined plate made of 2520 heat-resistant stainless steel plate slides the material into the cylinder space at the feed end along the inclined surface. The rotary drum dryer (model: Φ2.2×30m; 0.6 ~5r / min) for 40 minutes, the inlet temperature of the dryer is 800°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com