Pile foundation manufacturing method

A manufacturing method and a technology of pile foundations, which are applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems affecting the construction period, long period, and cumbersome construction procedures, etc., and achieve shortened construction period, simple construction method, and high cost. pile speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

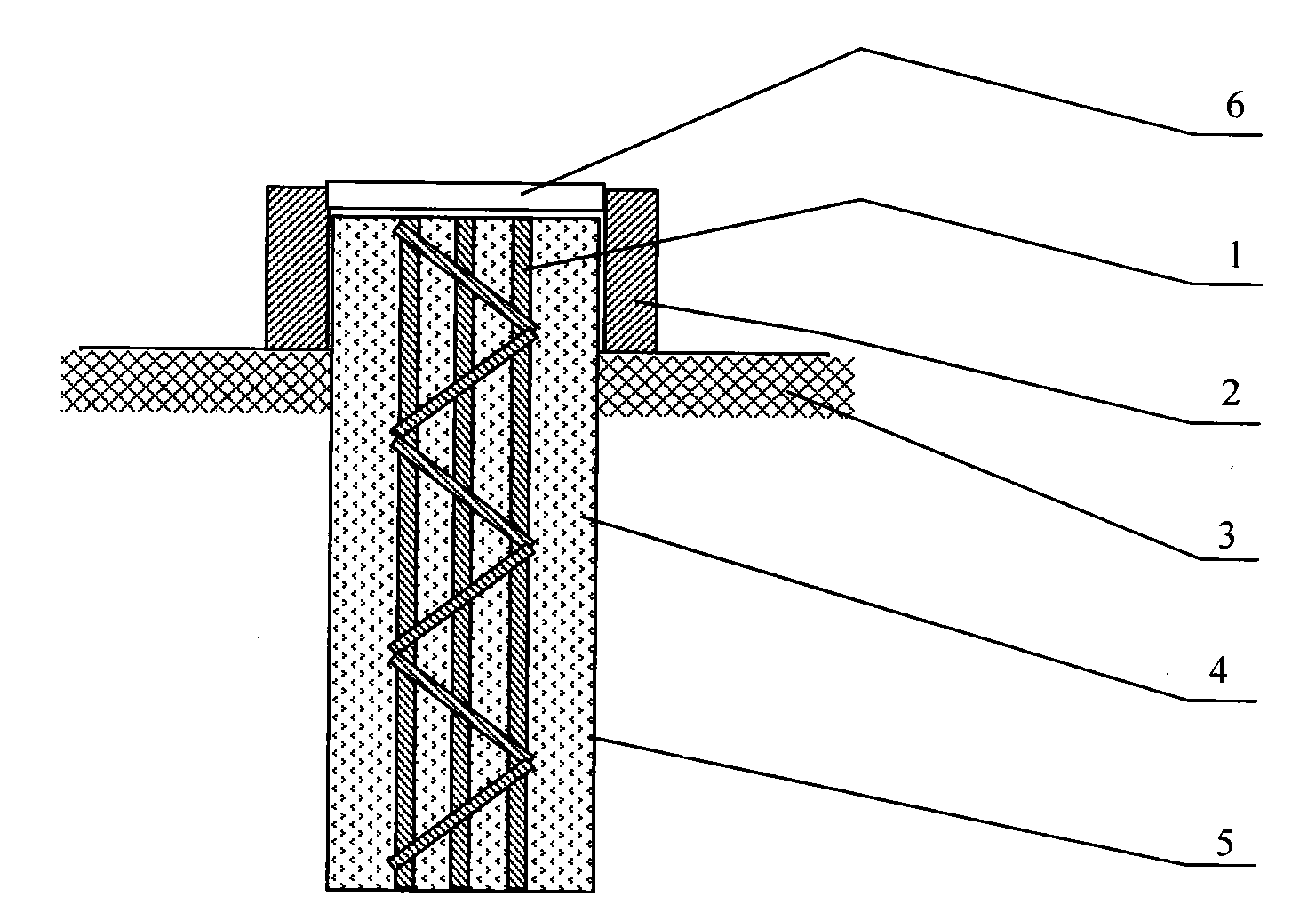

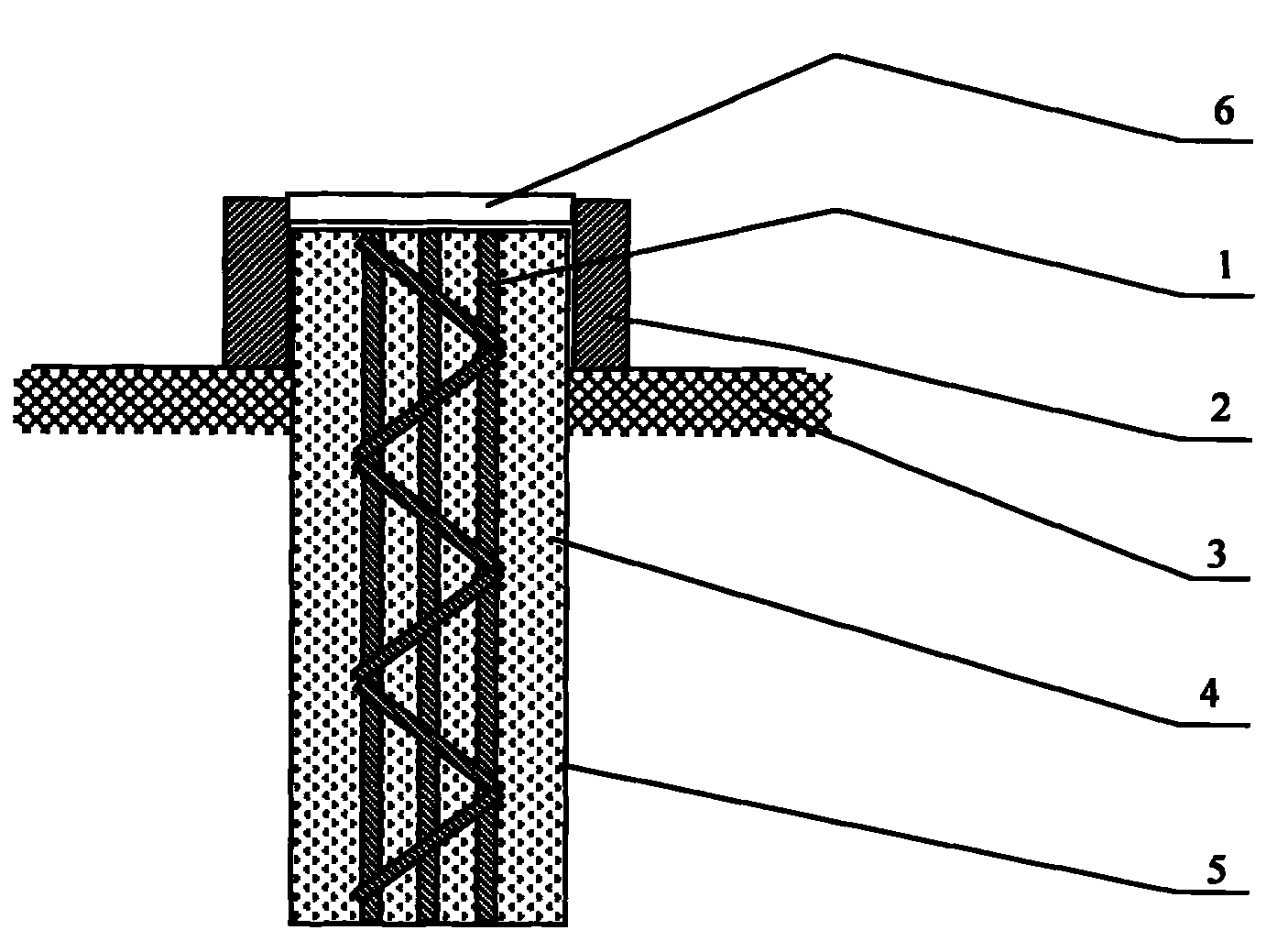

[0008] Example 1: Drill vertical boreholes 5 downwards on the ground 3, pour concrete into the boreholes 5, and lower the reinforcement cage 1 to form small-aperture piles. After the concrete pile body 4 reaches strength, the superstructure can be directly constructed Install.

[0009] Use a short auger drill to drill a vertical borehole 5 with a diameter of 300-350 in the ground 3. The depth of the borehole 5 is between 2-3 meters. Then, while lifting the hollow drill bit, pour C30 concrete into the borehole 5. And the small-aperture pile formed by lowering the reinforcement cage 1, the concrete pile body 4 can be directly constructed and installed on the superstructure after reaching the strength. Formwork 2 is installed around the hole 5 upper opening. Template 2 is cylindrical or square barrel-shaped. The upper surface of the concrete in the template 2 is pressed and covered with the top plate 6 . The top plate 6 is a steel plate.

[0010] In this embodiment, the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com