Combined flue

A combined, flue gas duct technology, applied in vertical pipes, building components, buildings, etc., can solve the problems of increased weight, waste of raw materials, inconvenient production, transportation, and installation, and achieves weight reduction, production convenience, and savings. The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

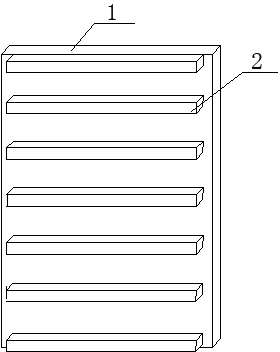

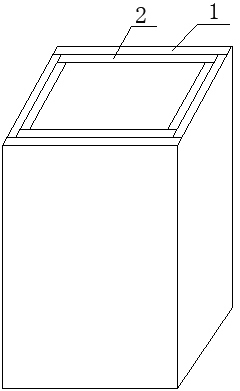

[0023] Refer to attached figure 1 , 2 , this embodiment is a single-hole flue gas channel, using more than two flue gas channel plates, which are matched and combined with each other to form a complete flue gas channel. There is space between the strips, and the strips are set on the surface of the flue gas duct plate to ensure the strength of the flue gas duct plate. There is space between the strips, which saves raw materials and reduces weight; The thickness of the flue gas channel plate can be reduced by arranging several strips on the top, and the thickness of the entire flue gas channel wall is the sum of the thickness of the flue gas channel plate and the plate strip. The section of the strip is rectangular, and a plurality of strips are arranged horizontally and parallelly on the flue gas duct plate.

Embodiment 2

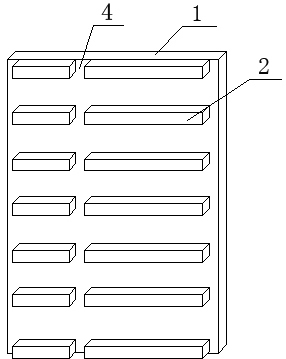

[0025] Refer to attached image 3 , 4 , the present embodiment is a two-hole flue gas channel, and the plate strips 2 on the corresponding two flue gas channel plates 1 are provided with corresponding longitudinal through grooves 4, and are also provided with longitudinal inner hole partitions 5, longitudinally The inner hole partition is inserted into two corresponding longitudinal through grooves, which divides the space in the flue gas channel into two to form a two-hole flue gas channel. The section of the strip is rectangular, and a plurality of strips are arranged horizontally and parallelly on the flue gas duct plate.

Embodiment 3

[0027] Refer to attached Figure 5 , in this embodiment, a flue gas duct liner 3 is arranged outside the strip 2, and the strip 2 is clamped between the flue gas duct plate 1 and the flue gas duct lining 3; between the strip and the flue gas duct plate , The fixed connection between the strip and the flue liner.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap