Reducer capable of regulating return difference

A reducer and adjustable technology, applied in the direction of mechanical equipment, transmission parts, gear transmissions, etc., can solve the problems of increased operating costs, increased processing costs, frequent accidents, etc. Effect of service life and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

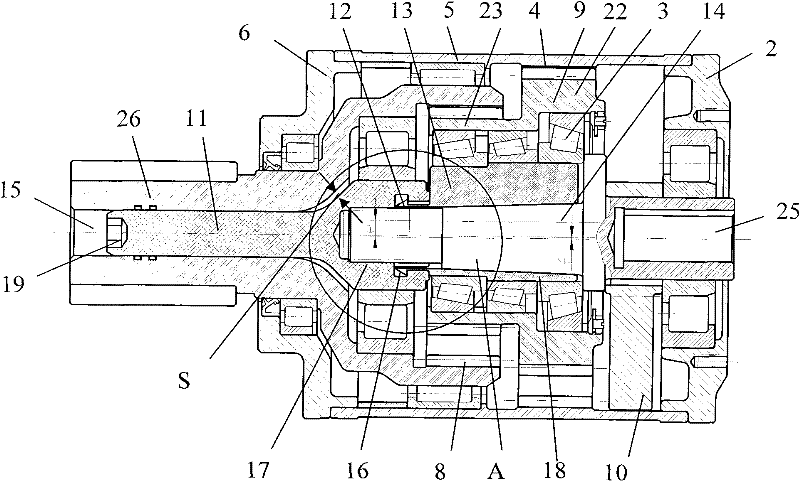

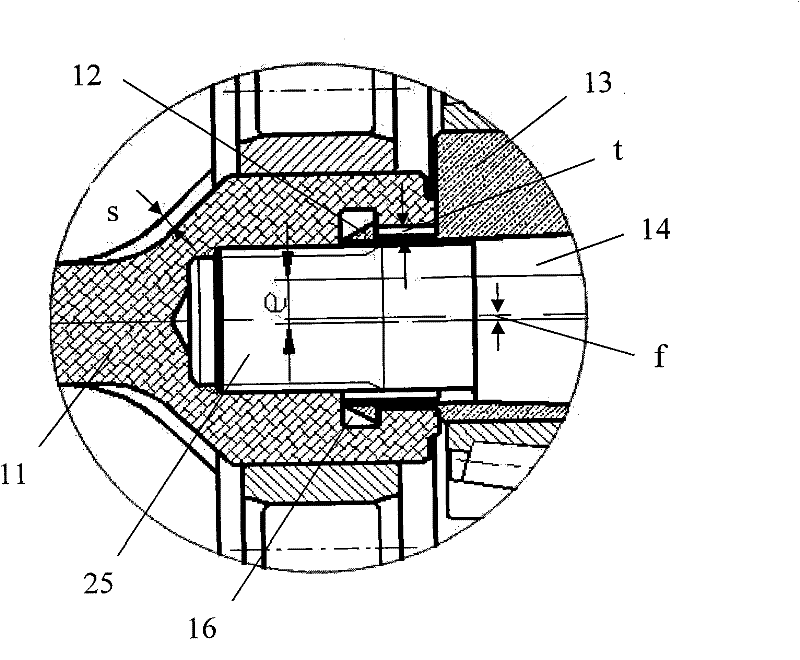

[0084] The second embodiment of the present invention can realize automatic adjustment of hysteresis.

[0085] Figure 7 It is a structural sectional view of the second embodiment of the speed reducer with adjustable hysteresis of the present invention.

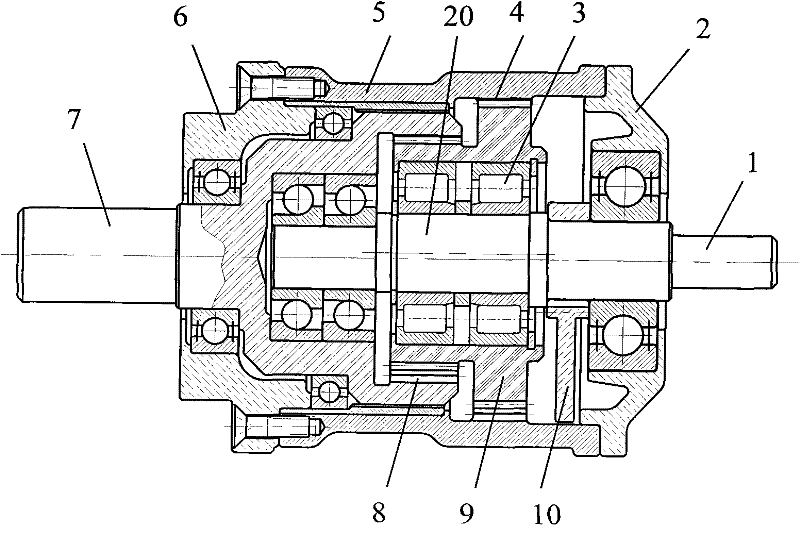

[0086] Such as Figure 7 As shown, the speed reducer with adjustable hysteresis of the present invention includes: a housing 5, a double planetary gear 9 mounted on the eccentric journal 42 of the input shaft through a bearing, an input shaft 41 with one end mounted on the input end cover 2, a mounting On the output shaft 39 on the output end cover 6, the input shaft remains at the center of the speed reducer, the first gear 22 of the double planetary gear meshes with the fixed ring gear 4 on the housing, and the second gear 23 of the double planetary gear Mesh with the gear 8 of the output shaft, the input shaft and the output shaft are in a straight line, and a balance weight 10 is also installed on the input shaft.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com