X-ray steel pipe seam detection supporting arm device

A welding seam detection and X-ray technology, which is applied in the field of X-ray detection devices, can solve the problems of inaccurate positioning, affecting the stability of the device, and poor control of adjustment and positioning, and achieves stable transmission, reasonable structural arrangement and high success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

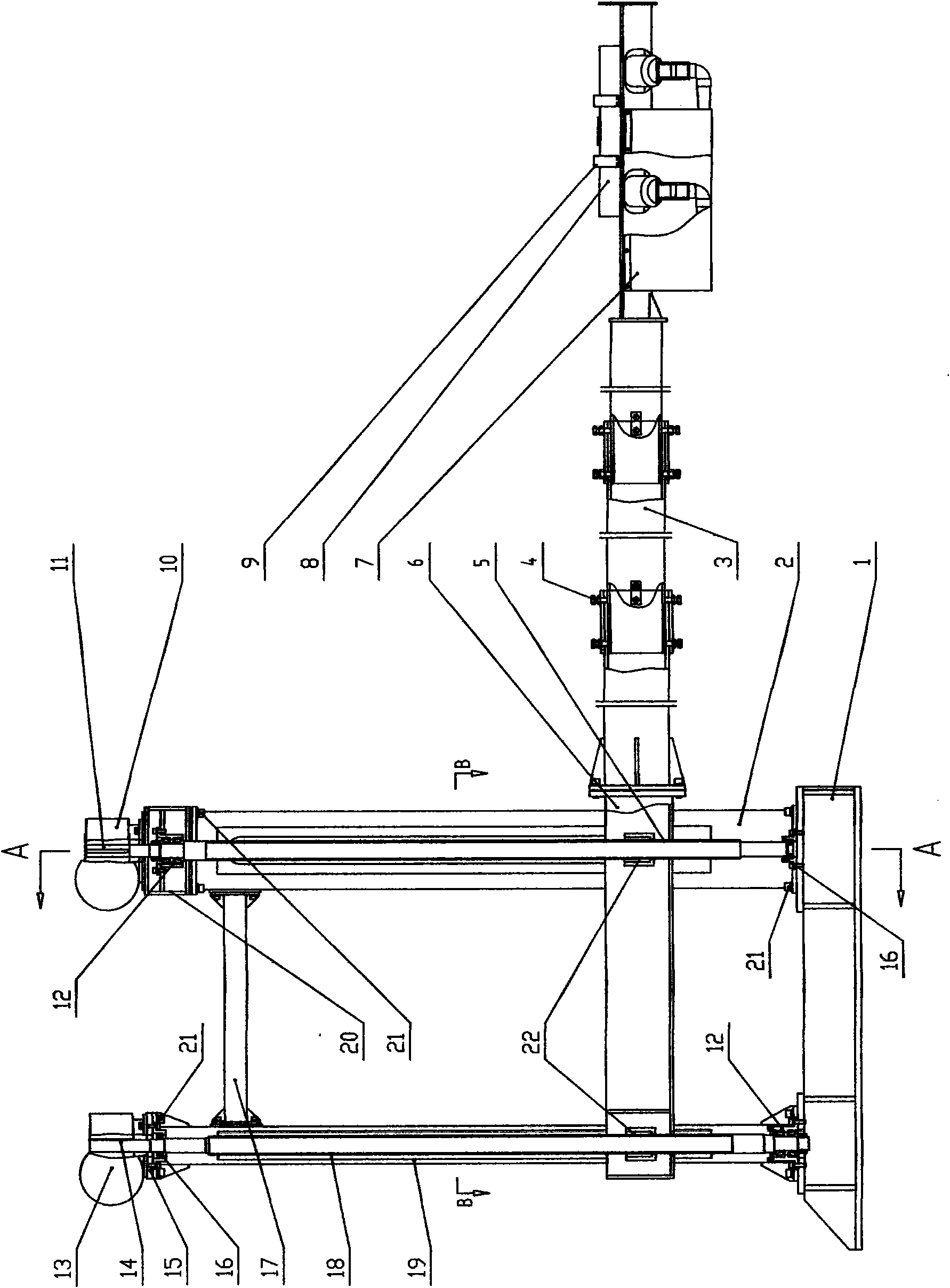

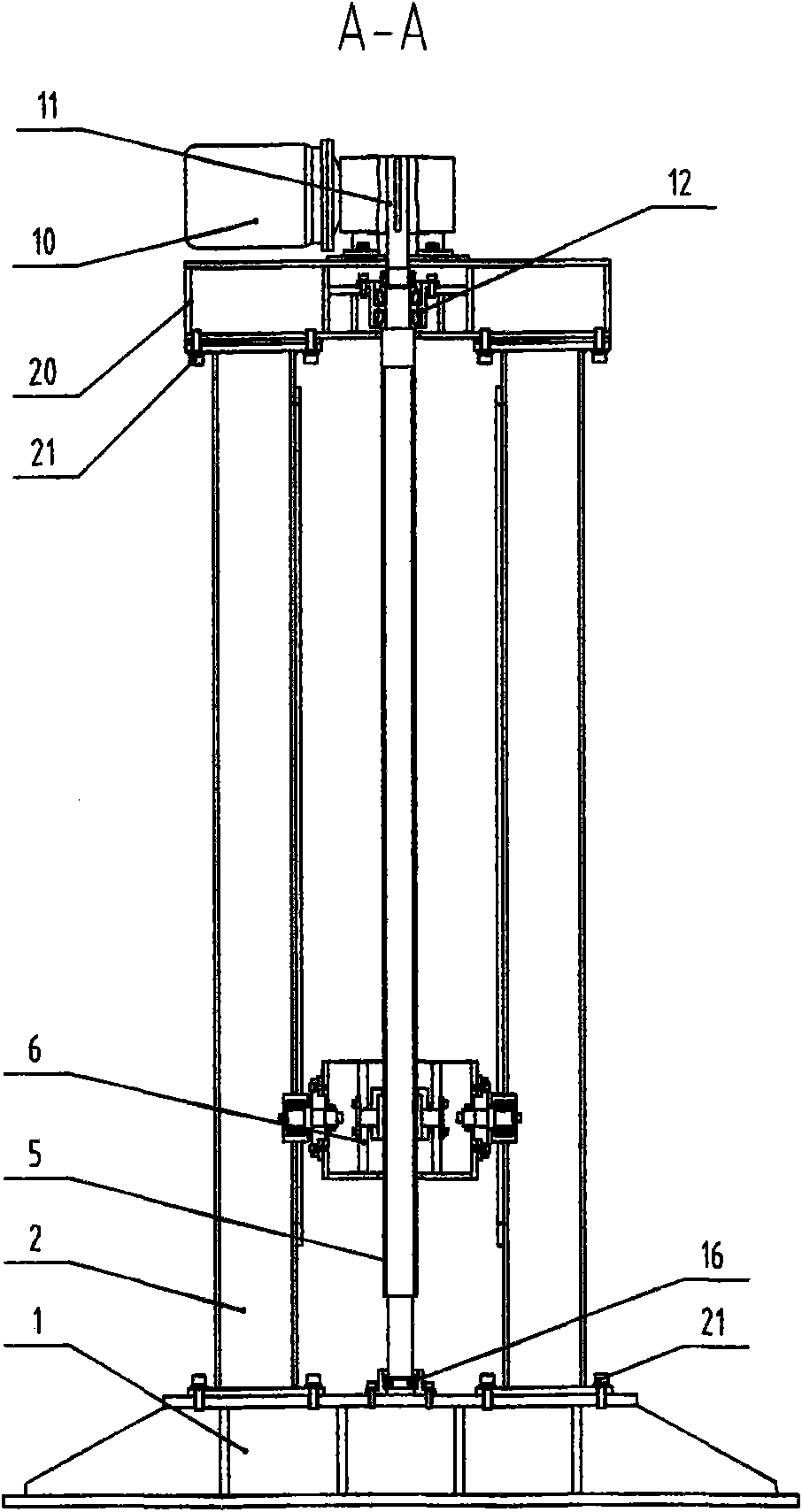

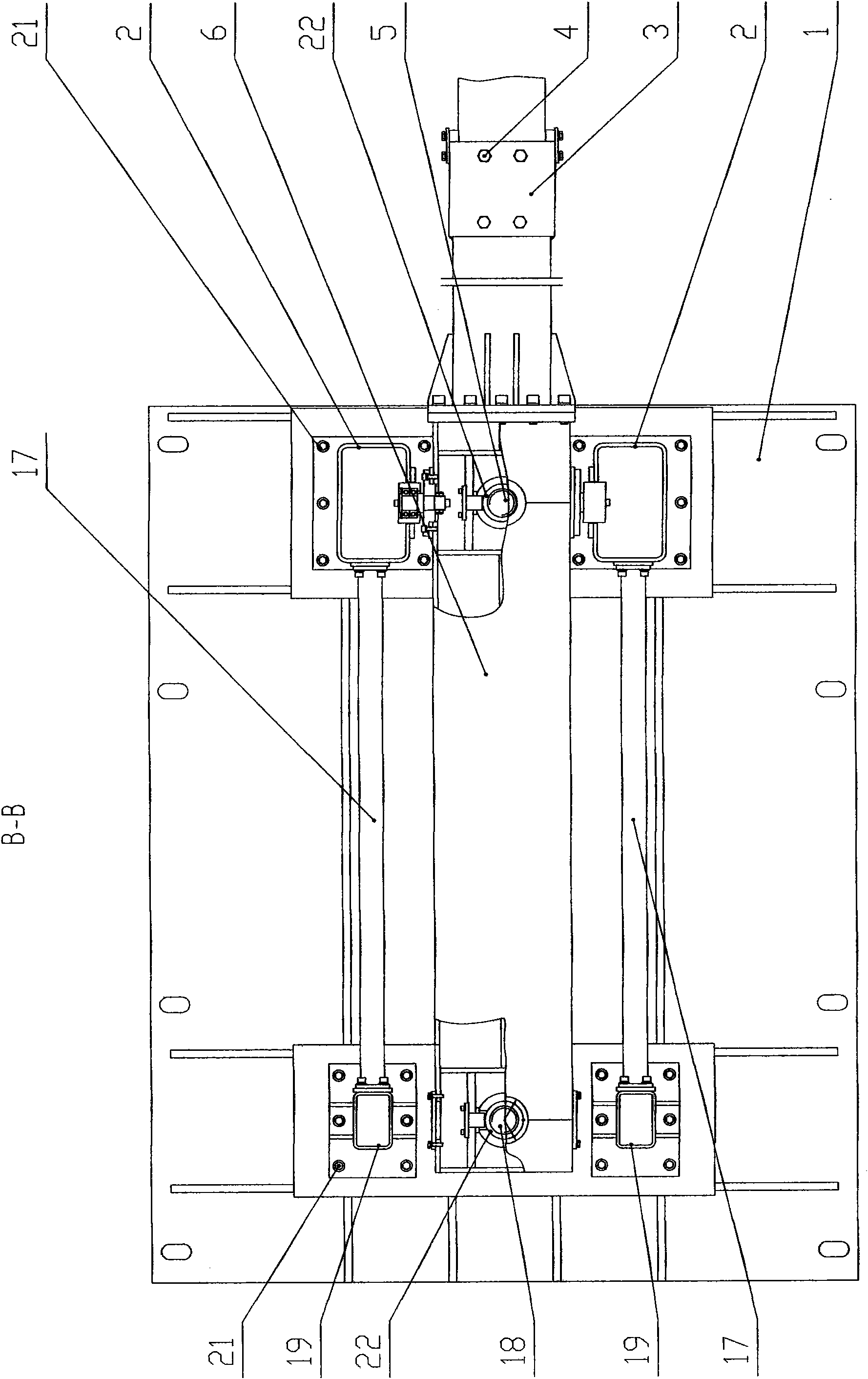

[0011] An X-ray steel pipe weld detection probe arm device, such as figure 1 , figure 2 and image 3 As shown, the bottoms of the two main columns 2 and the two auxiliary columns 19 are fixed on the base 1, and the upper ends are connected by front and rear reinforcement beams 17, which can increase the stability of the equipment. The main screw 5 is arranged between the two main columns 2 , and the auxiliary screw 18 is arranged between the two auxiliary columns 19 . The upper end of the main column 2 is connected with the beam 20 through the bolt 21, and the upper end of the main screw 5 is connected with the beam 20 through the bearing seat 12, wherein the upper and lower ends of the main screw 5 are respectively positioned by the bearing seat 12 and the bearing seat 16, The bearing seat 12 can bear the axial force, and is used for bearing the downward pulling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com