Fixture whole lamp aging detection line and operating mode thereof

A working method and detection line technology, applied in the field of aging detection of lighting lamps, can solve the problems of large assembly line structure, easy to cause danger, low aging efficiency, etc., and achieve improved aging efficiency, less floor space, and compact and reasonable equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

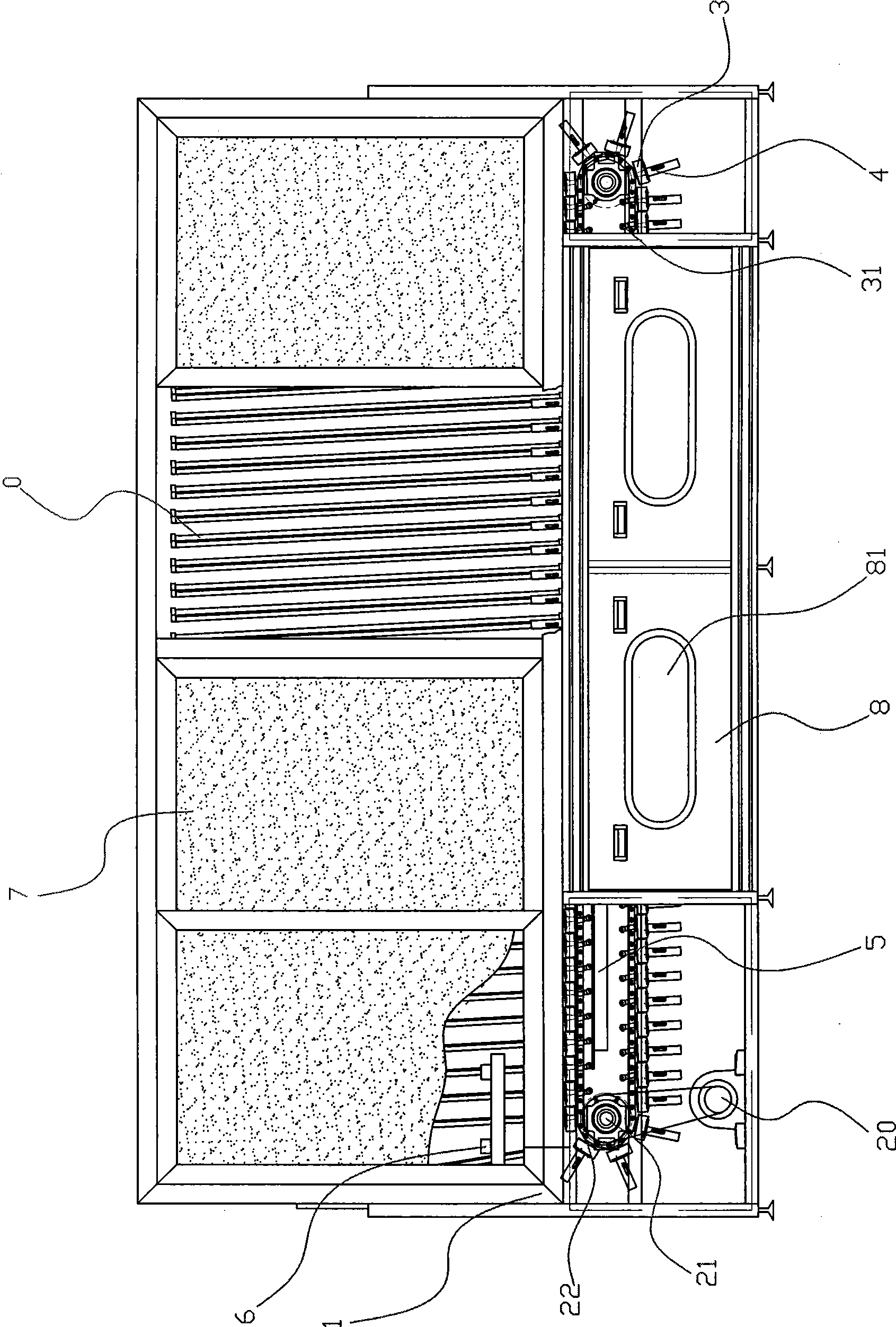

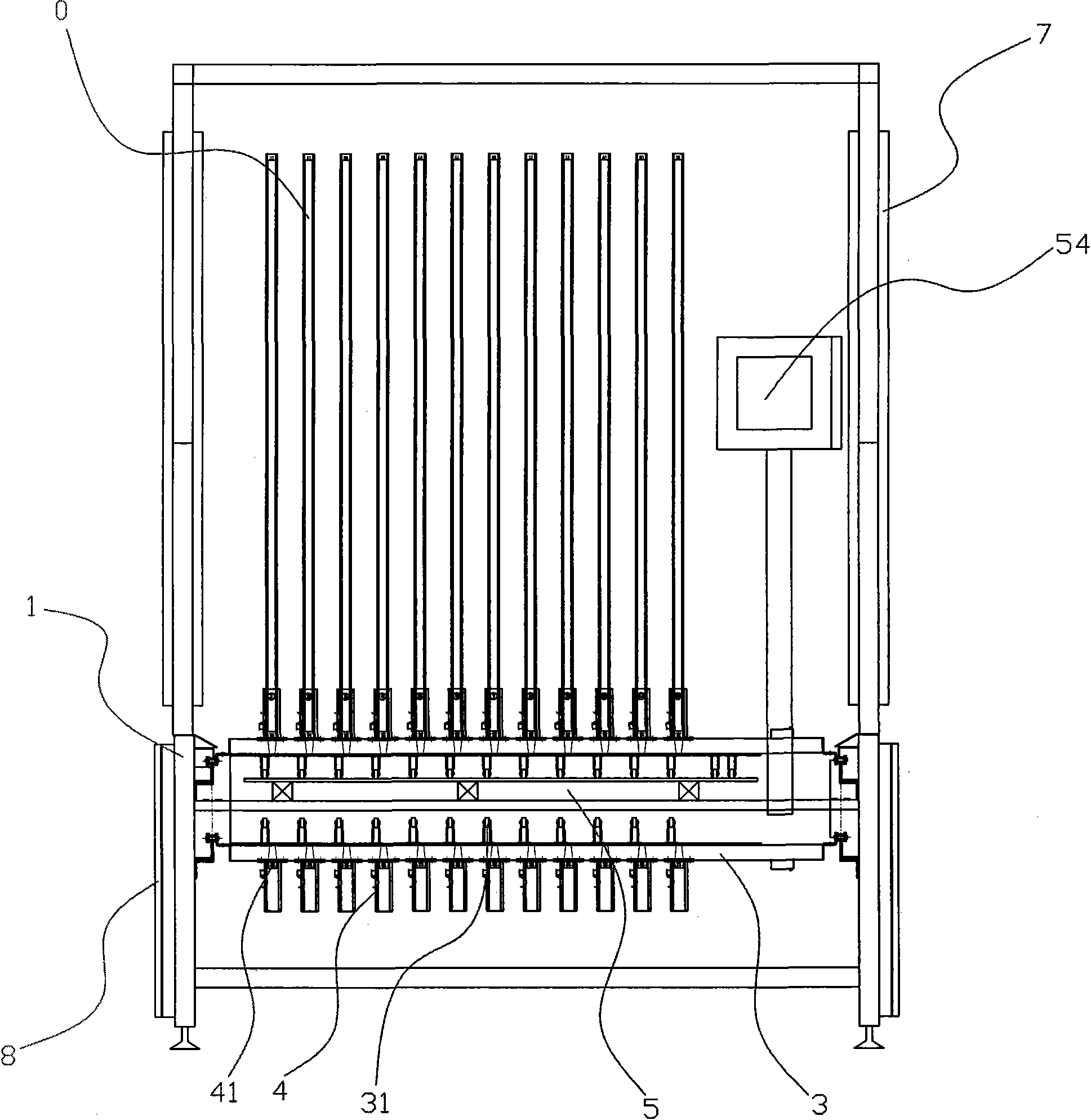

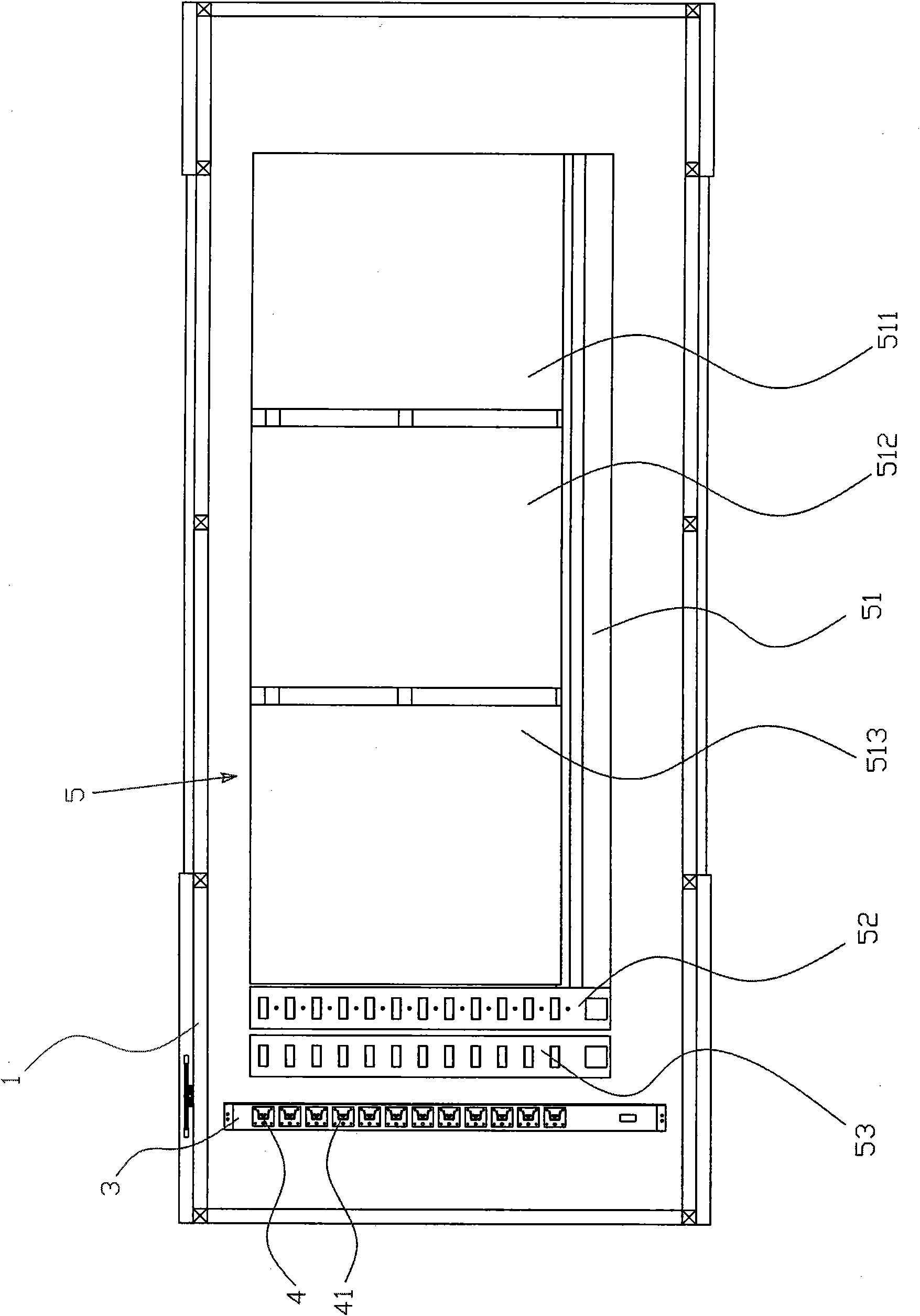

[0025] refer to Figure 1 ~ Figure 2 , the bracket whole lamp aging detection line provided by the present invention includes a frame 1 and a power mechanism 20. A conveying chain 22 is installed on the frame 1 through a transmission assembly 21, and the transmission assembly 21 is connected to the power mechanism 20 by transmission. The assembly 21 includes a transmission sprocket, and the driving and driven wheels balancedly distributed on the frame 1. During operation, the power mechanism 20 transmits to the transmission assembly 21 through the chain, and then drives the movement of the conveying chain 22 from front to back, and obtains a basic In the present invention, the conveying chain 22 is equipped with chain plates 3, and the chain plates 3 are arranged and installed above the conveying chain 22 in order, as the assembly of the fixed bracket whole lamp 0, wherein each chain plate 3 top is along its There are several bracket lamp clamping seats 4 arranged in a row in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com