Method for improving graphics critical dimension uniformity in mask

A key dimension and mask technology is applied in the field of semiconductor photolithography to improve the uniformity of key dimensions of mask patterns, and can solve the problems of optimal process condition deviation, difficult process control, and reduction of photolithography process window, etc. To achieve the effect of reducing the difference of etching uniformity, reducing the difference, and increasing the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

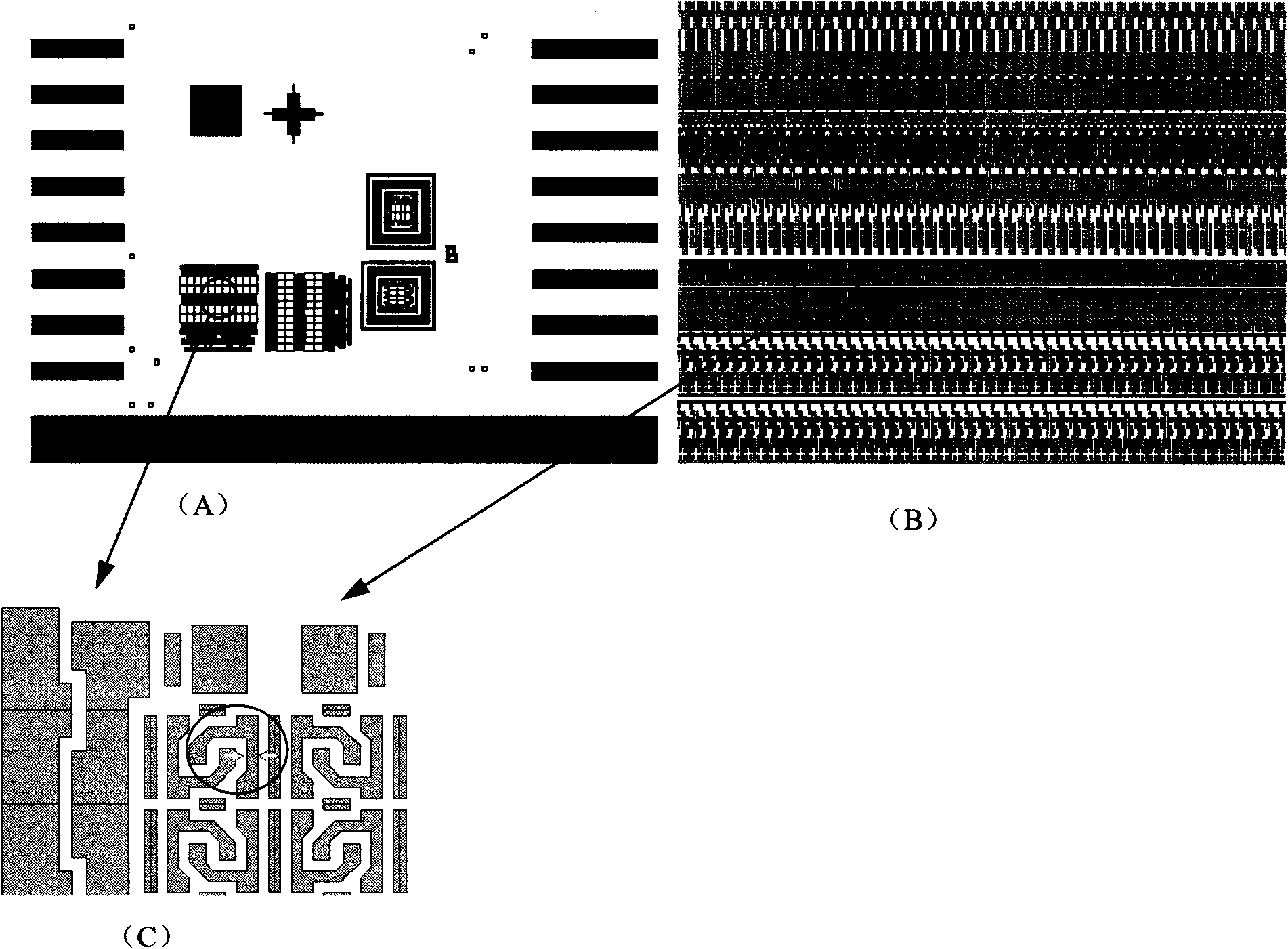

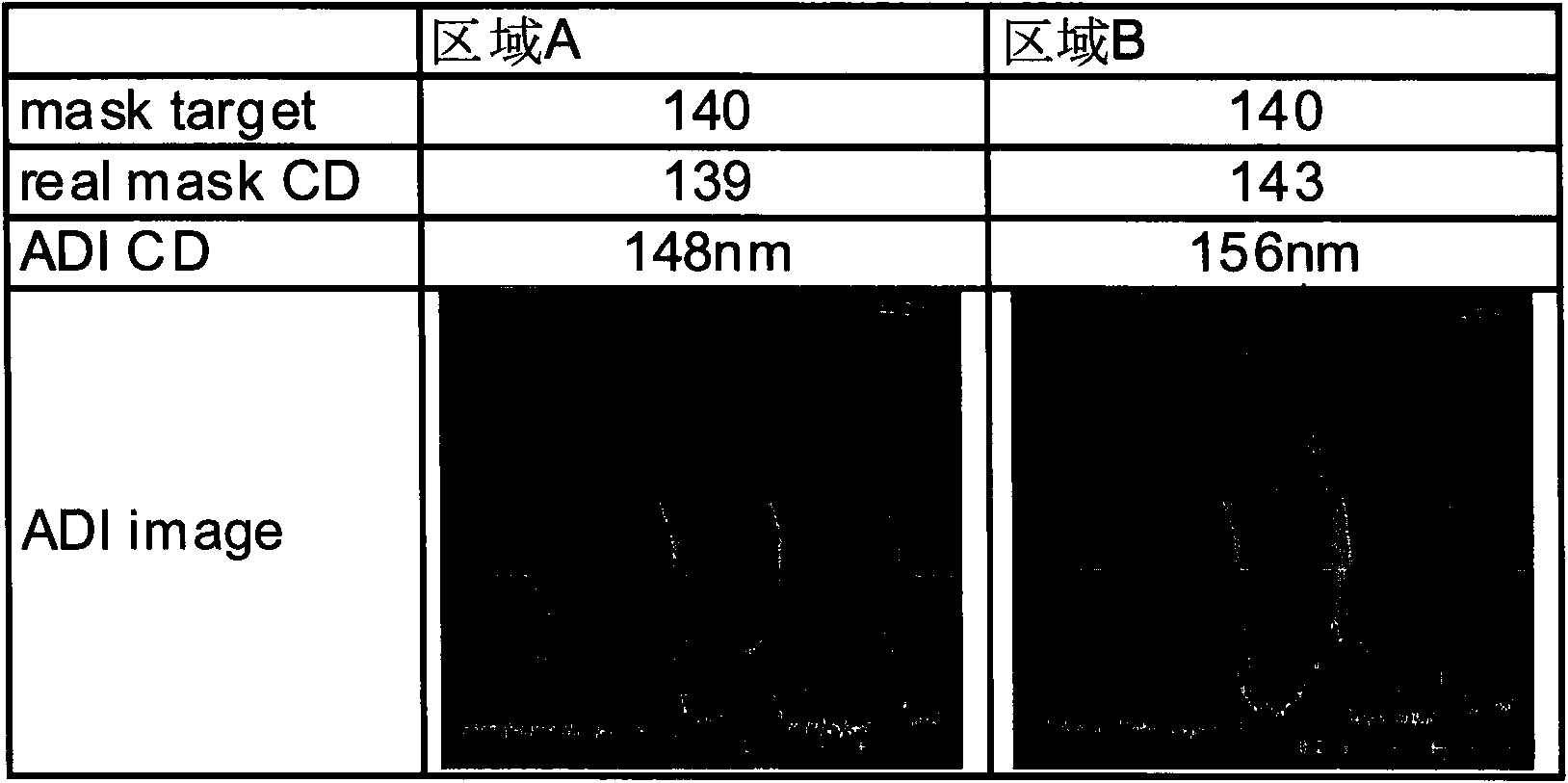

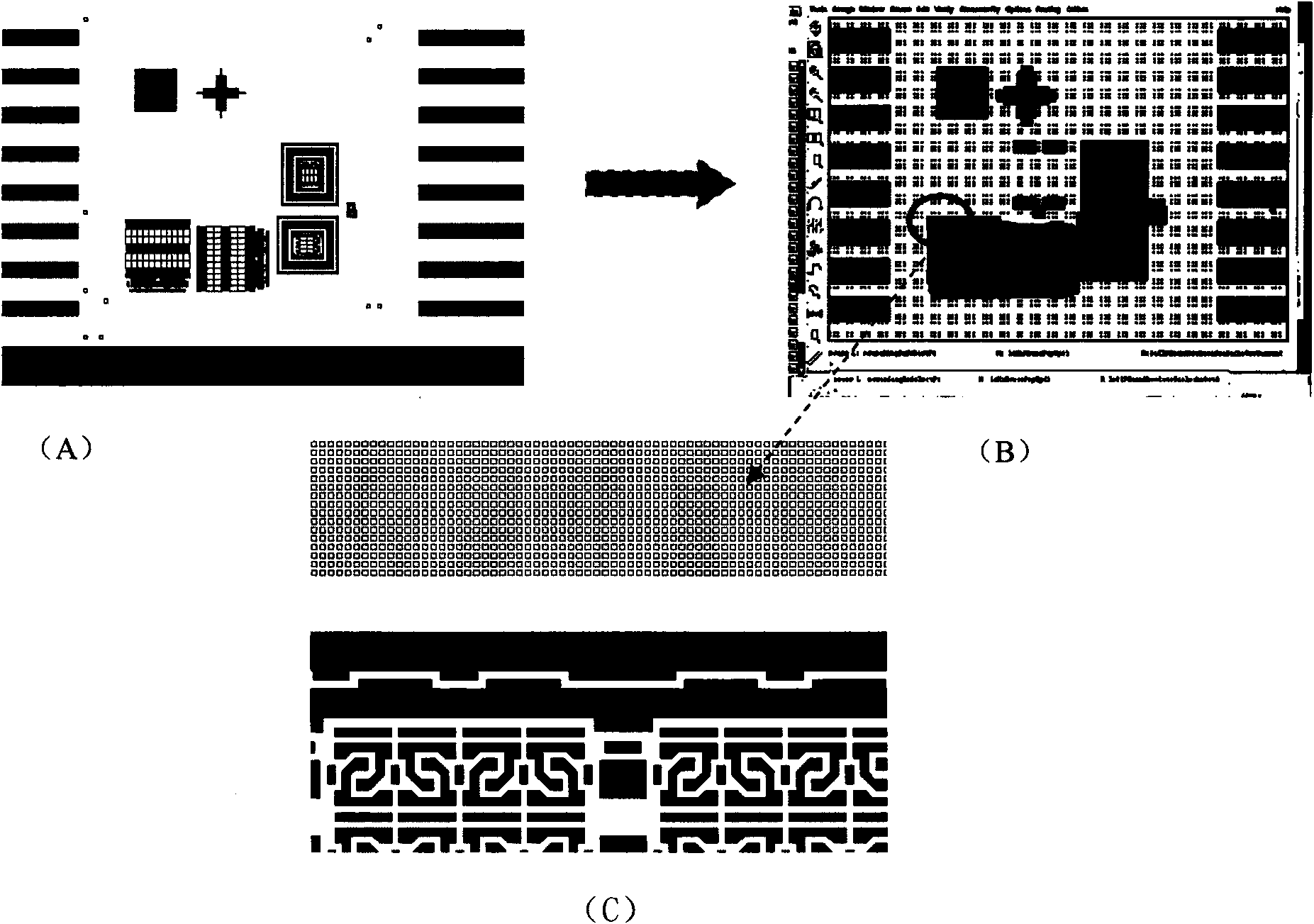

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] The concrete steps of the inventive method are as follows:

[0022] 1. In the photolithography process, before the mask plate is made, use OPC software or other related auxiliary software to insert auxiliary graphics in the layout according to certain rules. The general rule for inserting auxiliary graphics is: add multiple small-sized auxiliary graphics in the area where dummy patterns are not allowed to be inserted in the layout (chip design graphics). The "area where dummy graphics are inserted" usually refers to the dicing line or the open area far away from the working unit of the chip. Dummy graphics are allowed to be inserted, and small-sized auxiliary graphics are added in areas where dummy graphics are not allowed to be inserted to balance the difference in graphic density in different local areas. This small-sized au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com