Optimization operational method based on energy consumption analysis for power plant and system thereof

A technology of energy consumption analysis and optimized operation, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of operation optimization and adjustment guidance without practical significance, unable to guide the optimal operation of the unit, and reducing the energy consumption of the unit. , to achieve a high degree of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

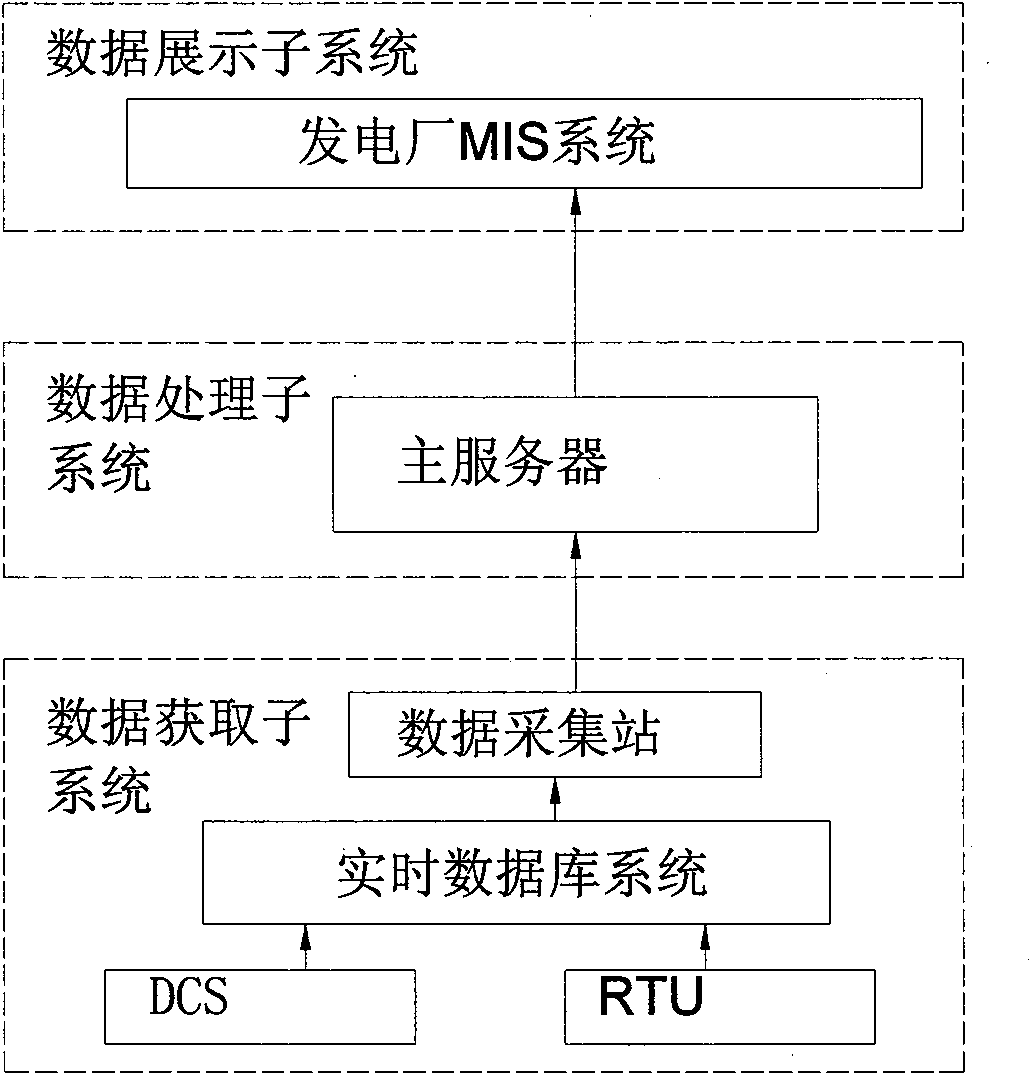

[0028] figure 2 It is a physical structure diagram of an optimized operation system based on energy consumption analysis of a power plant. It can be seen from the figure that all requirements of the system for the hardware environment of the power plant are that the power plant has built an MIS network system and can provide and obtain DCS data. An effective way to provide relational database support (such as Oracle database), provide a high-end PC server with better computing performance as the main server, that is to say, the system's requirements for the operating conditions of the power plant are completely based on the IT level the most common requirements. The system belongs to a production-oriented and data center-oriented information system between the DCS of the power plant and the power generation MIS. The entrance of the system is the power generation control system (DCS, RTU, PLC, etc.), and the exit is the power generation MIS or the power generation enterprise p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com