Process for producing bakery product

A production method and baking technology, which can be used in baked goods, baking, baking mixtures, etc., can solve problems such as unknown freeze drying, and achieve good quality and anti-aging effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

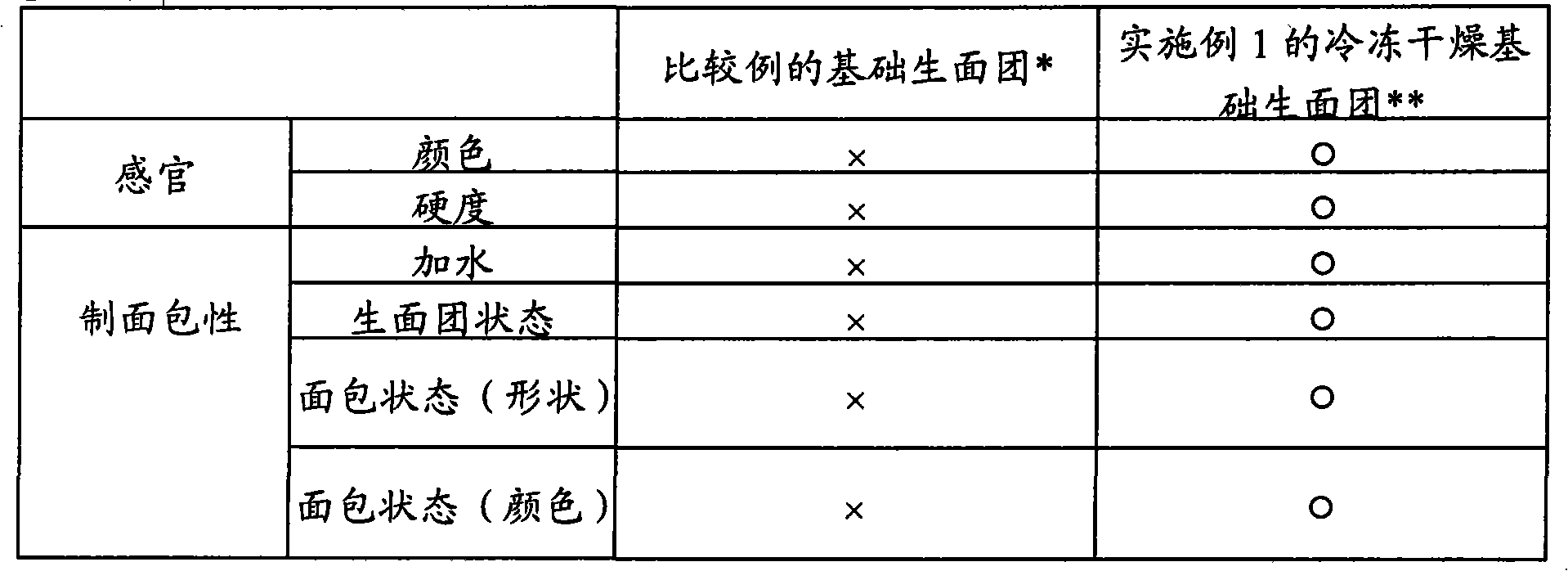

Examples

Embodiment 1

[0056] Process (1) Production of basic dough:

[0057] With respect to the amount (100 parts by weight) of all wheat flour required for making white bread, 40 parts by weight of wheat flour were used for making the base dough.

[0058] First, with respect to 40 parts by weight of wheat flour, 1 part by weight of sugar, 1 part by weight of salt and 1 part by weight of skimmed milk powder were added, mixed with 20 parts by weight of hot water and kneaded to obtain a basic dough. At this time, quickly measure the amount of the above-mentioned boiling water, then add wheat flour and other baked product ingredients at a temperature of about 99°C, and perform mixing and kneading. After the mixing and kneading is completed, the temperature of the base dough becomes about 70°C. Store the kneaded basic dough in cold storage (about 3-8° C.) for more than 8 hours.

[0059] Operation (2) freeze-drying:

[0060] The basic dough was rolled out to a thickness of about 2.5 cm, frozen at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com