Apparatus for washing and dewatering pulp

一种设备、纸浆的技术,应用在纸浆脱水、纸浆打浆/精浆方法、洗涤/置换纸浆处理液等方向,能够解决成本高、运输和安装难、大结构制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

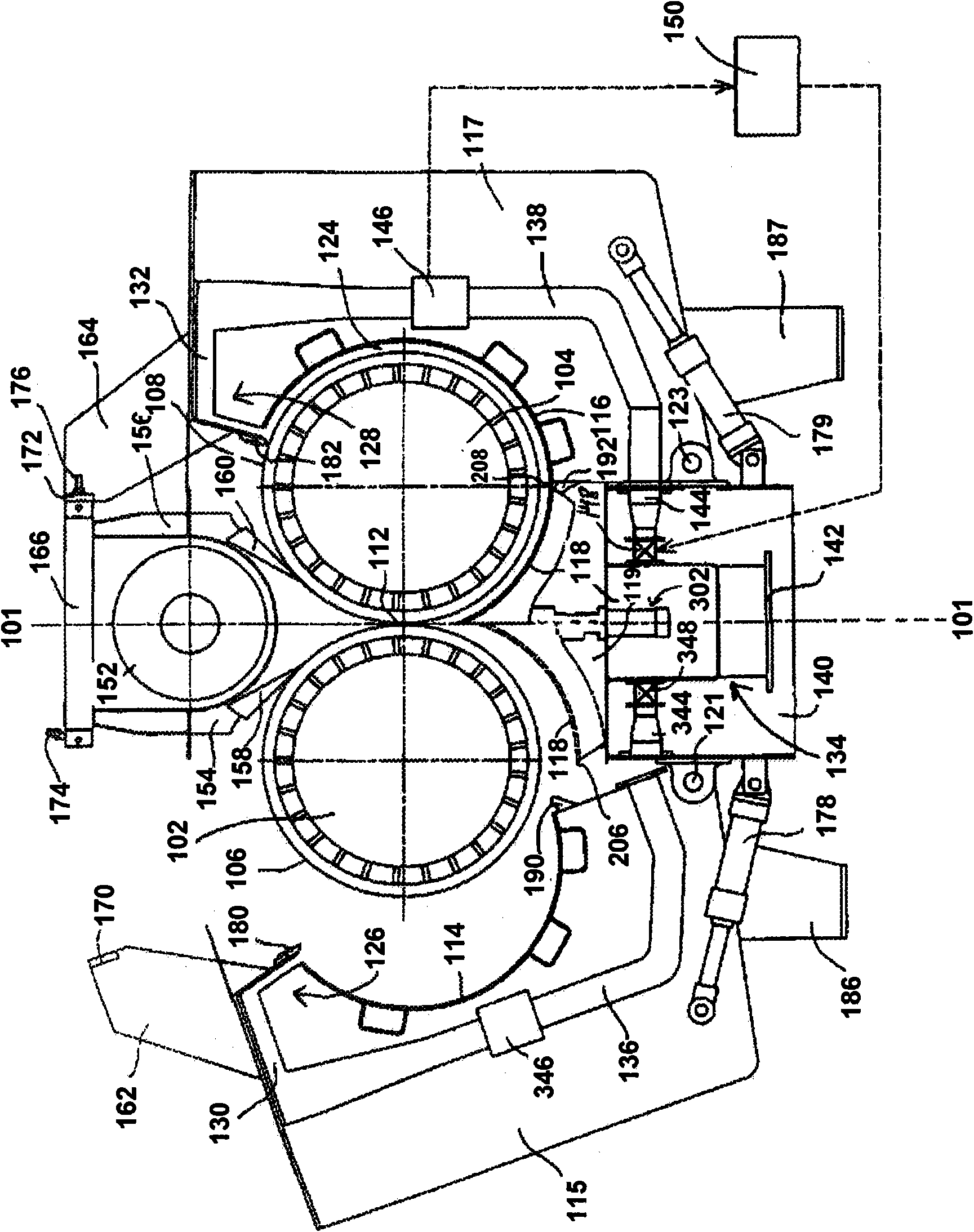

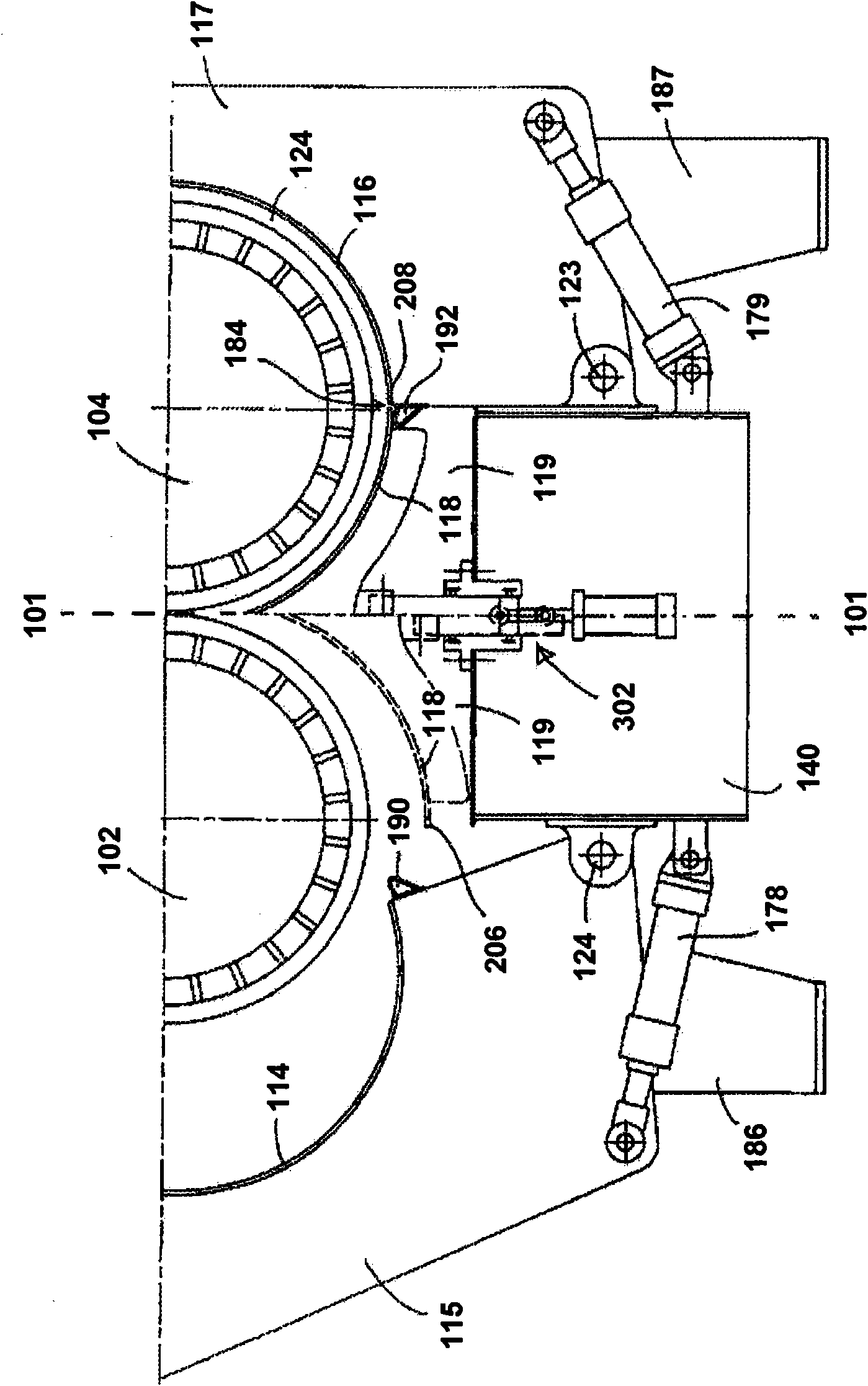

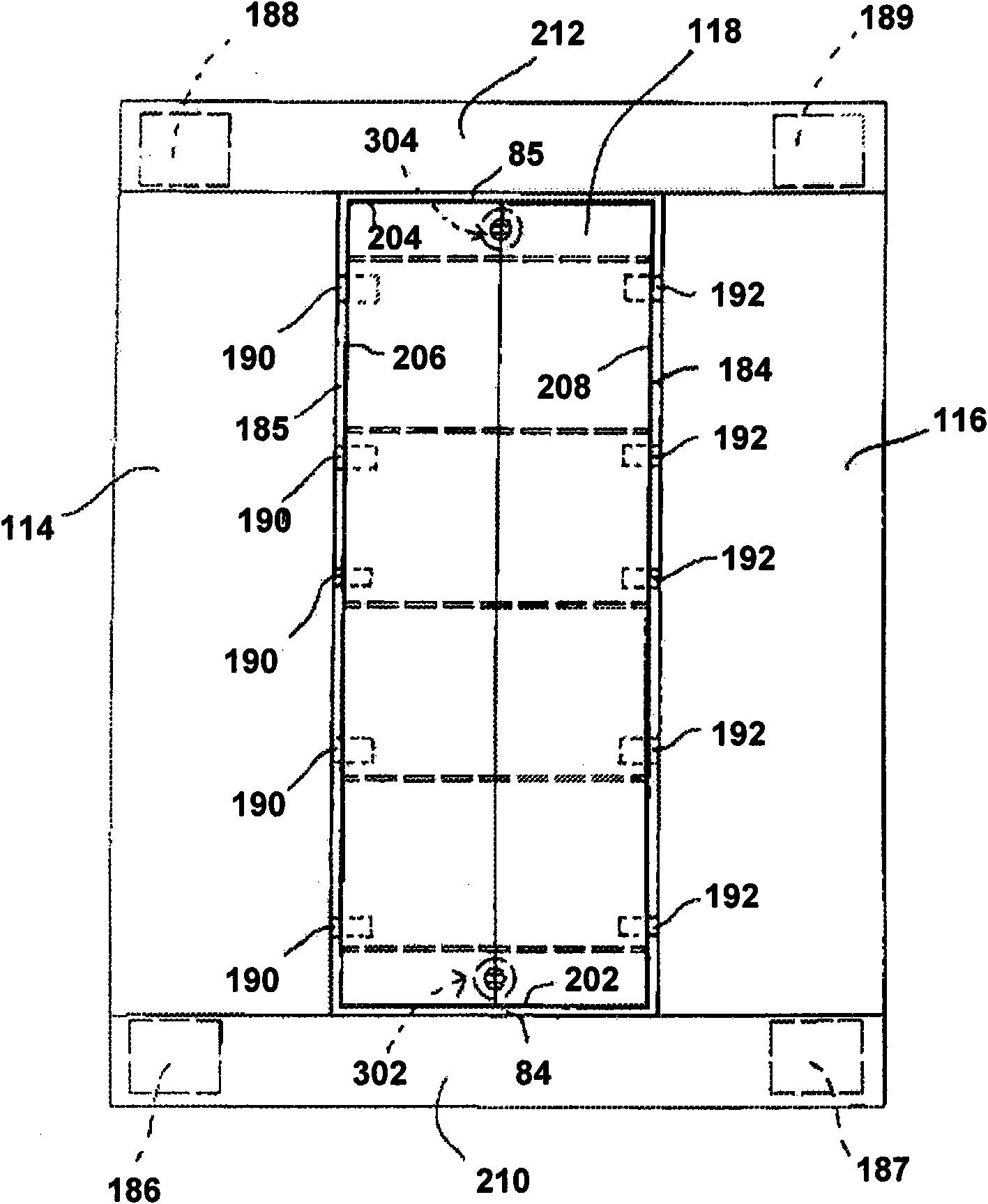

[0033] Figure 1A An embodiment of an apparatus for washing and dewatering cellulose-containing pulp according to the invention is shown. The device has a substantially symmetrical configuration with respect to the plane of symmetry 101, where Figure 1A In , the left side of the device (ie, the left side of the symmetry plane 101) shows the device in the open position, while the right side of the device (ie, the right side of the symmetry plane 101) shows the device in the closed working position. The apparatus comprises a first rotatable press roll 102 on the left side of the apparatus and a second rotatable press roll 104 on the right side of the apparatus, each press roll 102 , 104 having a permeable outer surface 106 , 108 . The outer surfaces 106, 108 are porous, ie provided with a plurality of pores, whereby the outer surfaces 106, 108 are permeable to the filtrate from the pulp extrusion. The shape of the hole is usually circular but can be of any shape. The press rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com