Honeycomb-spraying paper-plastic composite book cover and preparation method thereof

A manufacturing method, paper-plastic composite technology, applied to book covers, chemical instruments and methods, books, etc., can solve problems affecting the use of books, and achieve the effect of improving roll resistance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below according to accompanying drawing and specific embodiment the present invention is further described:

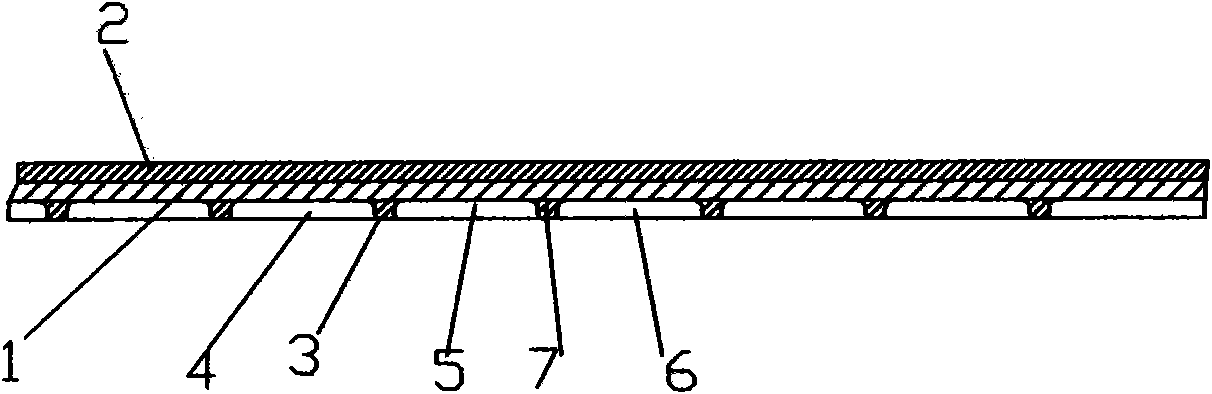

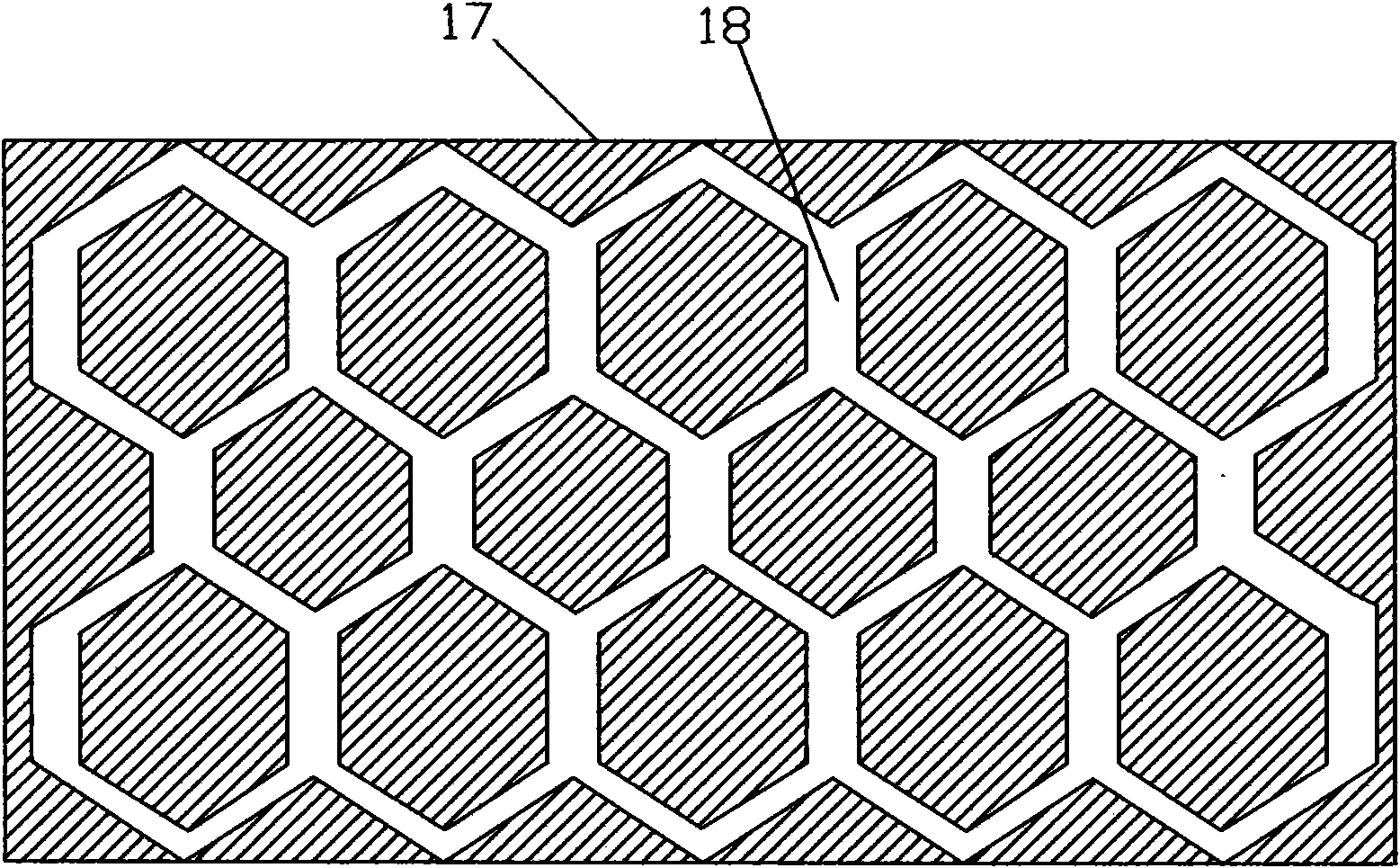

[0011] figure 1 The spray-coated honeycomb paper-plastic composite book cover includes plane paper 1 and plastic film 2, and the spray-coated honeycomb paper-plastic composite book cover is composed of plane paper 1, plastic film 2 and sprayed net 3; in order to improve the strength of plane paper 1, the plane The back of the paper 1 is spray-coated with a honeycomb mesh 3, the honeycomb mesh 3 is made of cured resin glue or cured transparent paint, the honeycomb mesh 3 and the back of the plane paper 1 form a honeycomb groove 4, and the honeycomb groove 4 is composed of multiple, There is a honeycomb bar 7 between the first honeycomb groove 5 and the second honeycomb groove 6, and the front of the plane paper 1 is combined with the plastic film 2.

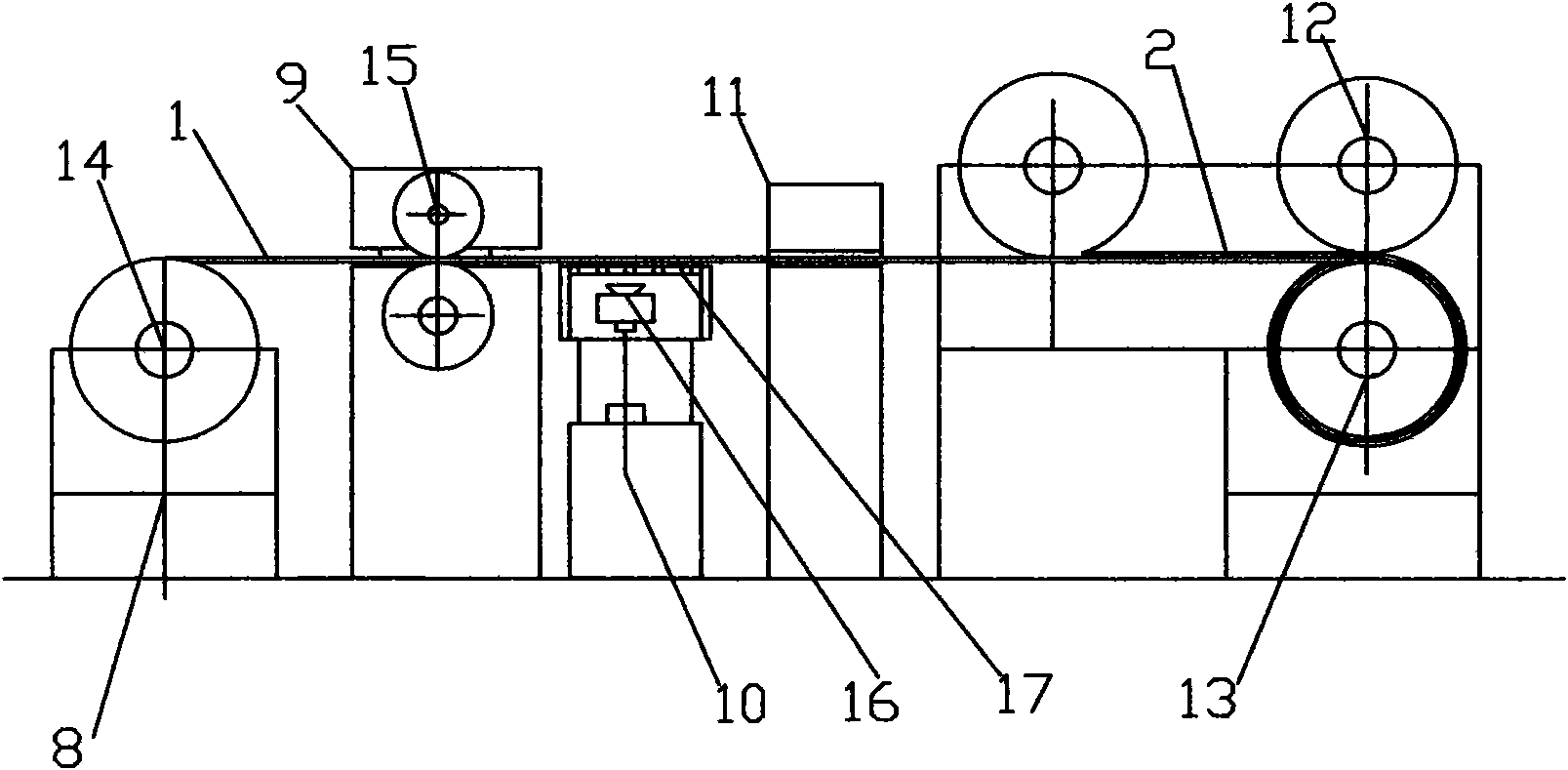

[0012] The manufacturing method of the spray-coated honeycomb paper-plastic composite book cover is: plane paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com