Elastic longitudinal joint device used for shield tunnel segments in swelling soil areas

A shield tunnel segment and expansive rock technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of difficult implementation, high cost, high cost and difficult to achieve, and reduce equivalent stiffness and reinforcement. the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

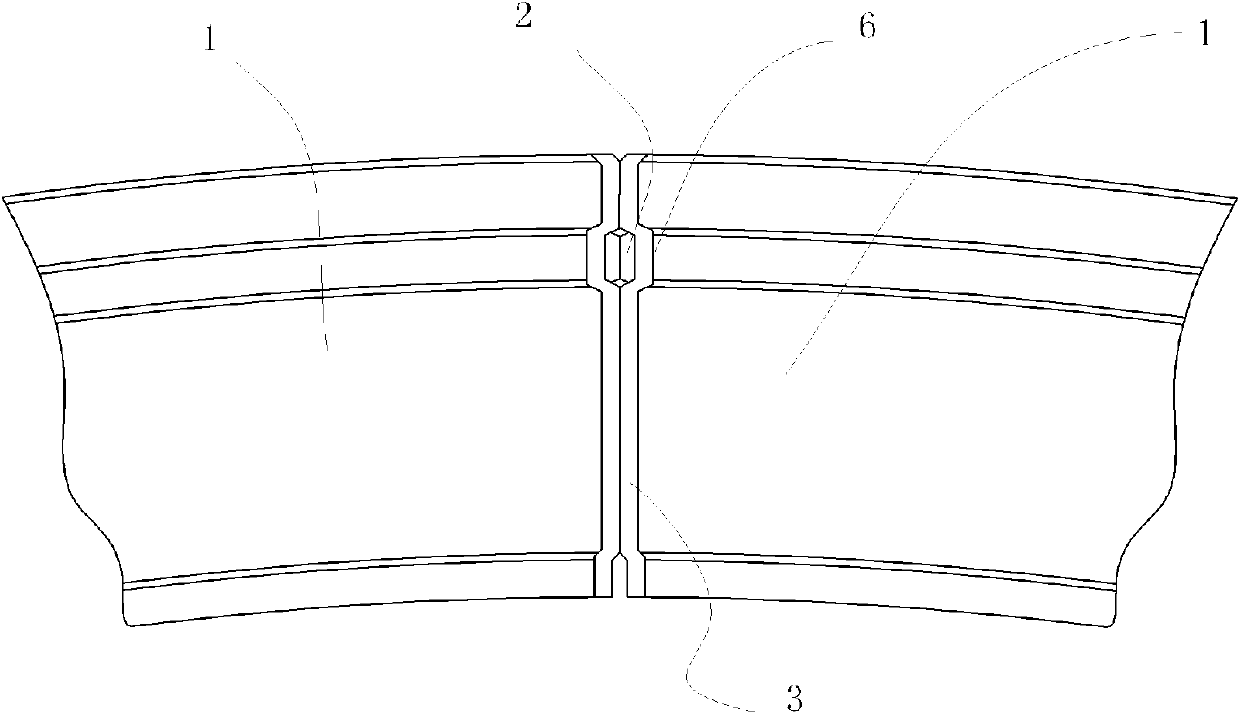

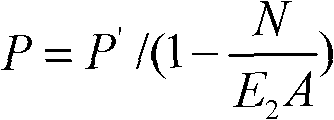

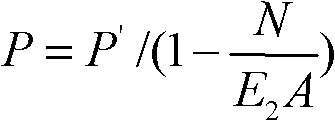

[0016] figure 1 It is shown that a specific embodiment of the present invention is: an elastic longitudinal seam device for shield tunnel segments in expansive rock and soil areas, including sealing grooves 6 respectively provided on the longitudinal seam walls of connected segments 1 And the gasket 2 in the sealing groove 6. The longitudinal seam wall of the segment 1 is provided with a rubber belt 3 covering the entire longitudinal seam wall, and the rubber belt 3 at the seal groove 6 is located between the seal groove 6 wall and the gasket 2, and the thickness P of the rubber belt 3 is as follows: The formula determines:

[0017] P = P ′ / ( 1 - N E 2 A )

[0018] Among them, P' is the thickness of the rubber belt after being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com