Smart camshaft phase regulator of variable valve timing system of engine

A valve timing and engine technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large output torque, difficult arrangement of the front end of the engine, excessive axial size, etc., and achieve small torque loss and compact structure , The effect of reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0027] preferred embodiment

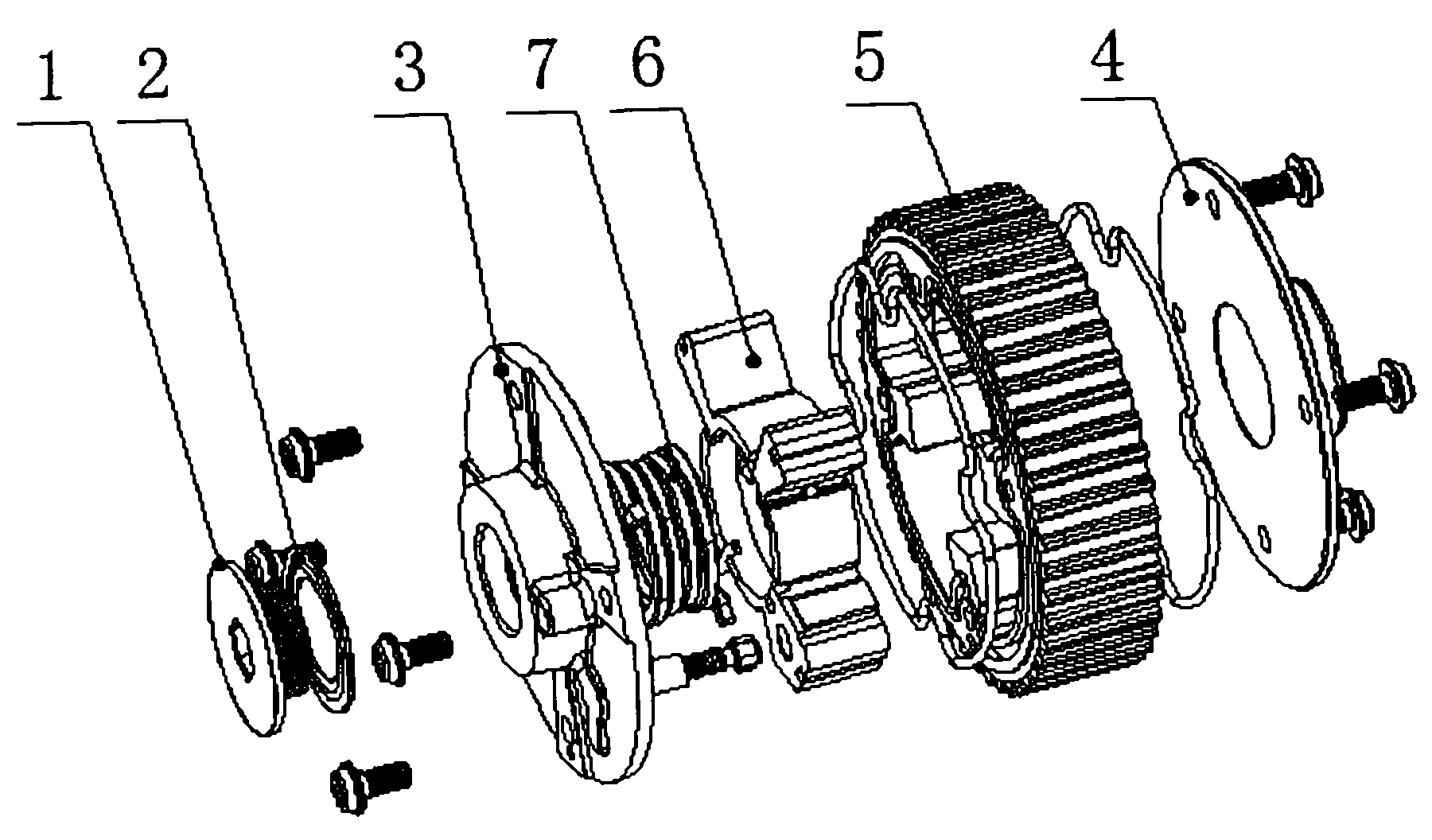

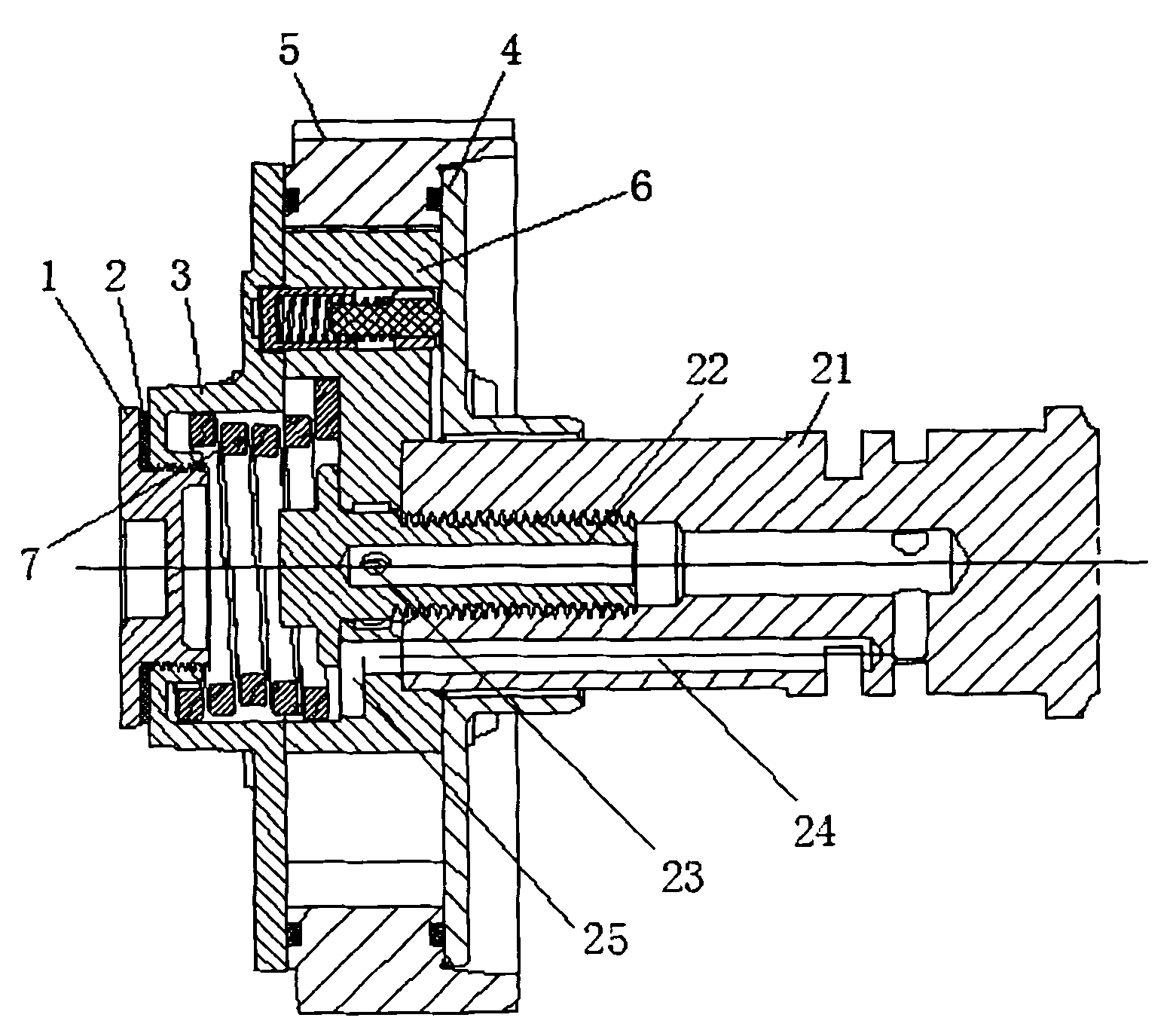

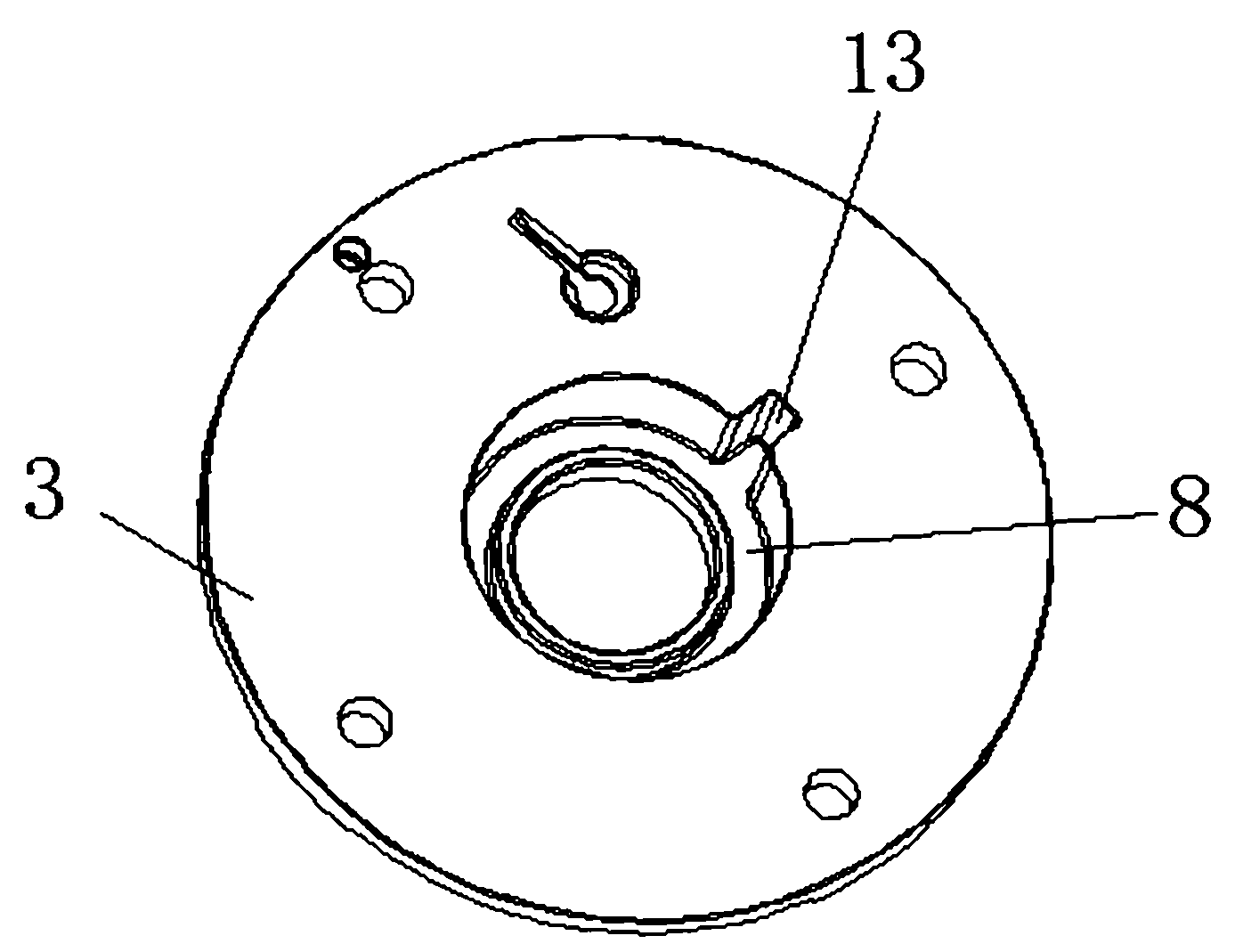

[0028] Such as Figure 1-Figure 9 The camshaft smart phaser of the variable valve timing system of the engine shown, including screw plug 1, gasket 2, front end cover 3, rear end cover 4, hollow shell 5, rotor 6 and return spring 7, screw plug 1 and the gasket 2 are connected to the front end cover 3, the front end cover 3 and the rear end cover 4 are respectively connected to the housing 5, the inside of the housing 5 is hollow, the rotor 6 is placed in the housing 5, and the front end cover 3 is concaved to form a The radial groove 8, the middle part of the rotor 6 near the front end cover 3 is concaved to form a groove 9, and the return spring 7 is placed in the cavity formed by the radial groove 8 and the groove 9. The structure of the present invention integrates the rotor 6, the oil chamber, the housing 5 and the return sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com