Method for repairing drainage pipeline without water supply suspended

A technology for drainage pipelines and drainage pipes, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as economic loss, traffic impact, high power consumption, etc., achieve chemical bond stability, save money, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

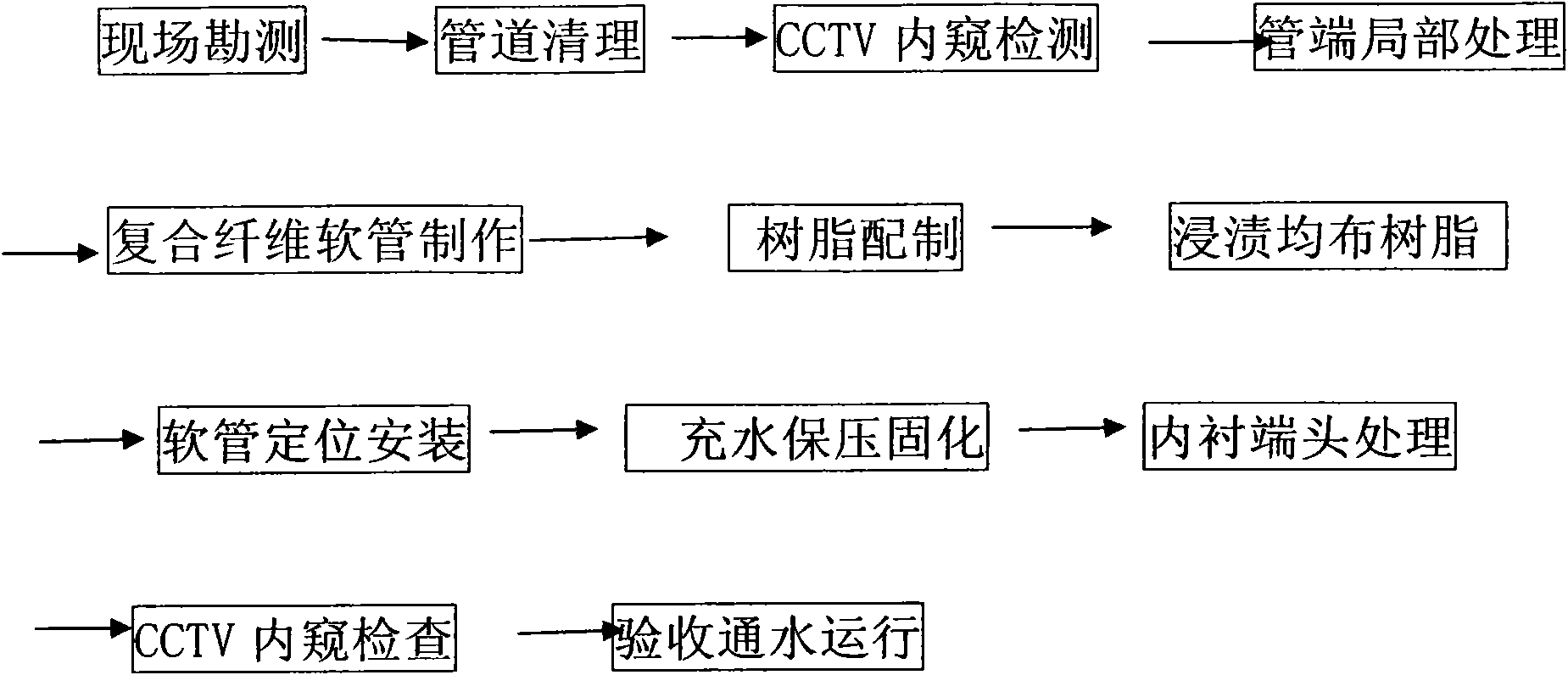

[0035] The method for repairing the drainage pipeline without stopping water of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0036] The method for non-stop water repair of drainage pipelines of the present invention is based on the following design ideas:

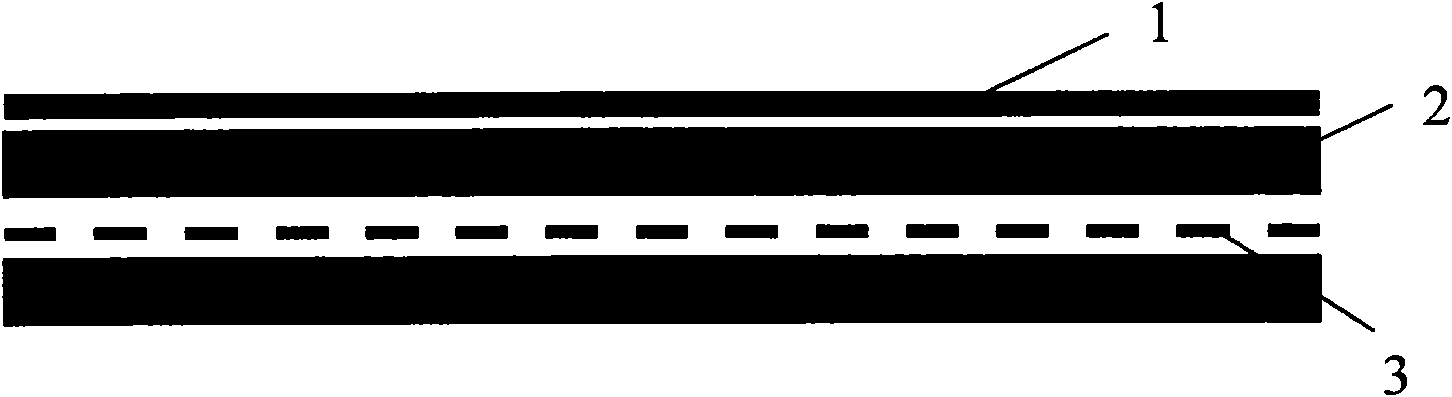

[0037] The non-excavation and non-stop water resin lining repair technology of drainage pipes is to use resin-soaked composite fiber hoses as the lining material of the pipelines. The inner and outer sides of the hoses are water-resistant and corrosion-resistant waterproof membranes. Use the drag-in method to drag the hose into the pipeline to be repaired, and after positioning and fixing, use the sewage in the pipeline to fill water and maintain pressure, so that the hose is continuously opened in the drainage pipeline and attached to the pipe wall, and finally the resin is soaked. The hose is closely attached to the inner wall of the pipe to be repaired. After a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com